-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 20, 2024 10:11 Back to list

42 Inch Pipe Cap for Effective Pipeline Closure and Protection Solutions

Understanding 42-Inch Pipe Caps Applications and Benefits

In industrial settings, the integrity and functionality of piping systems are crucial for efficient operations. One of the essential components that help maintain this integrity is the pipe cap. Specifically, the 42-inch pipe cap serves a vital role in various applications, ensuring that pipelines remain secure, safe, and operational. This article delves into the significance, applications, and benefits of 42-inch pipe caps in modern engineering and construction.

What is a Pipe Cap?

A pipe cap is a fitting used to seal the end of a pipe. These caps are typically made from materials such as carbon steel, stainless steel, or PVC, depending on the requirements of the application. The primary purpose of a pipe cap is to prevent liquids and gases from leaking out, to protect the pipe's internal environment from external contaminants, and to maintain a consistent pressure within the pipeline.

The Importance of Size

The designation 42-inch refers to the diameter of the pipe that the cap is designed to fit. This size is significant as it is commonly used in large-scale industrial applications, including oil and gas, water treatment facilities, and construction projects. A 42-inch pipe cap is robust enough to handle the substantial pressures that may be experienced within the system.

Common Applications

1. Oil and Gas Industry In the oil and gas sector, 42-inch pipe caps are frequently used to seal pipeline ends during construction or maintenance activities. They play a critical role in preventing leaks and ensuring that the system is safe and functional.

2. Water Treatment Facilities Water treatment plants utilize large diameter piping to transport water efficiently. Pipe caps are employed to seal ends during repairs or to temporarily close off sections of the pipeline, thus ensuring effective maintenance without disrupting the overall system.

3. Construction Projects In the construction industry, pipe caps are often used in situations where pipelines are laid but not yet put into full operation. This helps to protect the pipeline from environmental damage due to dirt, debris, or water infiltration.

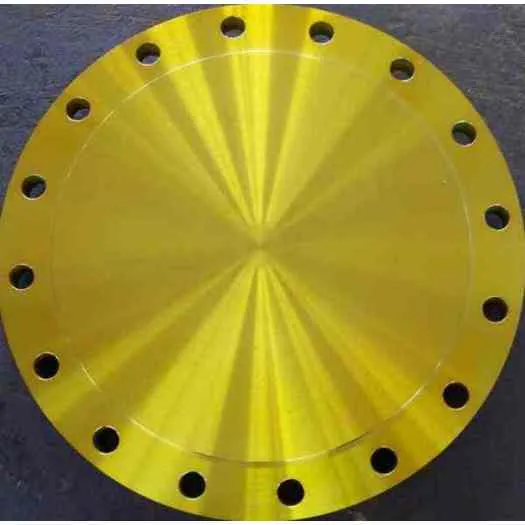

42 inch pipe cap

4. Mining Operations In mining, large pipes are used to transport various materials, including slurry and waste. Caps are essential to secure these pipes against external elements and to manage pressure effectively.

Benefits of Using 42-Inch Pipe Caps

1. Leak Prevention One of the most significant advantages of using pipe caps is leak prevention. This is crucial in high-pressure systems where even the smallest leak can lead to catastrophic failures and safety hazards.

2. Cost Efficiency By sealing pipes properly, organizations can avoid costly repairs and downtime associated with leaks and contamination. This cost-saving aspect is particularly vital for industries that rely on large-scale operations.

3. Durability Many 42-inch pipe caps are designed to withstand harsh conditions. Their robust manufacturing materials ensure long-lasting performance, even in extreme environments, reducing the frequency of replacements.

4. Safety Sealing pipes effectively contributes to overall safety in industrial operations. By preventing leaks and protecting the integrity of the pipeline, pipe caps help avert potential accidents that could harm workers and the surrounding environment.

5. Flexibility Pipe caps offer the flexibility to modify piping systems according to changing operational needs, allowing for easy maintenance and upgrades without significant overhauls.

Conclusion

In conclusion, 42-inch pipe caps are essential components in various industries, providing safety, efficiency, and reliability to piping systems. Their role in preventing leaks, protecting pipelines, and ensuring operational integrity cannot be overstated. As industries continue to evolve and grow, the importance of high-quality pipe caps will likely remain significant, underpinning the continuous development of safer and more effective infrastructure. Whether in oil and gas, water treatment, construction, or mining, the benefits of using a 42-inch pipe cap are clear, making it a fundamental aspect of modern engineering practices.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024