-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 20, 2024 16:00 Back to list

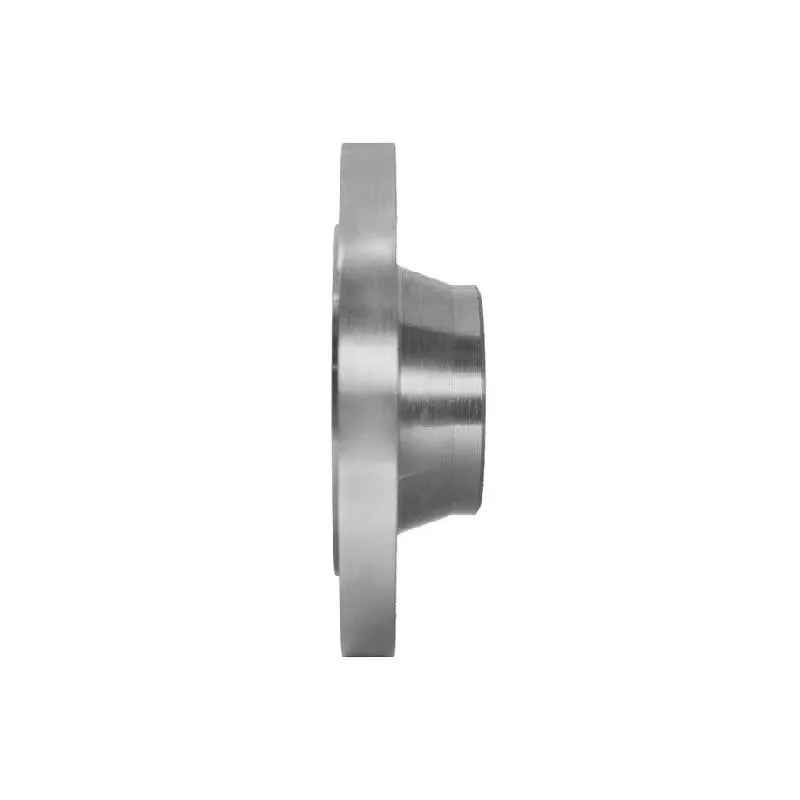

4 inch flange

The Significance of 4-Inch Flanges in Industrial Applications

Flanges are mechanical components used to join pipes, valves, and other equipment in various industrial systems. Among the numerous specifications, the 4-inch flange has gained prominence for its versatility and effectiveness in a multitude of applications. This article delves into the significance of 4-inch flanges, examining their design, applications, and benefits in various industries.

Understanding 4-Inch Flanges

A flange is essentially a flat piece, typically made from metals or other materials, that features holes at regular intervals to accommodate bolts or screws. The 4-inch designation refers to the nominal diameter of the flange, which is crucial for ensuring compatibility with pipes and fittings. Flanges come in different types, such as weld neck, slip-on, blind, and threaded flanges, each serving specific applications.

The 4-inch flange typically conforms to various standards set by organizations such as the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME), which provide guidelines for dimensions, tolerances, and material specifications. Because of this standardization, professionals can ensure that their piping systems are reliable and safe.

Applications of 4-Inch Flanges

4-inch flanges are widely utilized across several industries including oil and gas, water treatment, chemical processing, and HVAC systems. They facilitate the connection of pipes that transport liquids or gases, ensuring that the flow is maintained and leakage is minimized. In the oil and gas industry, for example, 4-inch flanges are crucial for joining pipelines that carry crude oil, natural gas, and refined products under high pressure.

In chemical processing facilities, 4-inch flanges provide secure connections for reactors, separators, and storage tanks that handle corrosive materials. The durability of the material used for the flanges is critical, as it ensures that the risks of leaks and failures are significantly reduced. Flanges made from stainless steel, for instance, offer excellent corrosion resistance, making them ideal for such environments.

4 inch flange

Advantages of 4-Inch Flanges

One of the primary benefits of utilizing 4-inch flanges is their ease of installation. With the right tools and expertise, flanges can be easily bolted together, providing a strong and reliable connection without the need for complicated welding processes. This not only speeds up the installation time but also reduces labor costs.

Additionally, 4-inch flanges allow for easy disassembly, which is beneficial for maintenance and inspection. In industries where equipment undergoes regular servicing, the ability to quickly remove and replace flanged connections can lead to significant uptime improvements.

Another advantage is the versatility of the 4-inch flange size itself. A 4-inch diameter is commonly used, striking a balance between flow capacity and physical space, making it a popular choice for many different applications across various sectors. This size is manageable and can handle substantial fluid flow, making it suitable for both small and medium-sized systems.

Conclusion

In summary, 4-inch flanges play a crucial role in ensuring the integrity and efficiency of industrial piping systems. Their standardization in design, coupled with their ease of installation and maintenance, has made them a prevalent choice in numerous industries. Whether in the oil and gas sector, chemical processing, water treatment, or HVAC systems, these flanges serve as essential components that contribute to the reliability and safety of operations.

As industries move towards more automated and efficient systems, the design and material technology of flanges continue to evolve, promising even better performance and durability. Understanding the attributes and applications of 4-inch flanges not only aids engineers and technicians in making informed choices but also underscores their strategic importance in modern industrial applications.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024