-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 15, 2024 21:35 Back to list

50mm flange

Understanding 50mm Flange A Comprehensive Guide

In the world of manufacturing and construction, the flange plays a pivotal role in connecting pipes, valves, and other equipment. Among the various types of flanges available, the 50mm flange is particularly notable due to its versatility and widespread application. Understanding its features, uses, and installation processes is crucial for engineers, technicians, and anyone involved in piping systems.

What is a Flange?

A flange is a mechanical component used to join two parts together. It generally consists of a flat piece of metal with holes for bolts and a raised or recessed area to accommodate a gasket. This design allows for a strong, leak-proof seal between two connected items, making flanges essential in numerous industries, including oil and gas, water treatment, and HVAC systems.

Features of a 50mm Flange

The term 50mm flange typically refers to the diameter of the flange or the piping it is intended to connect. The 50mm measurement indicates the nominal size, which can vary in actual dimensions depending on the flange type and standards. Common materials used in the construction of 50mm flanges include stainless steel, carbon steel, and PVC, allowing for a wide range of applications based on environmental factors and fluid characteristics.

Flanges are also categorized based on their design, including slip-on, weld neck, blind, and threaded. Each type has its own advantages, and the choice largely depends on the specific requirements of a project. For example, slip-on flanges are easier to align and install, while weld neck flanges provide a more robust connection, making them ideal for high-pressure applications.

Applications of 50mm Flanges

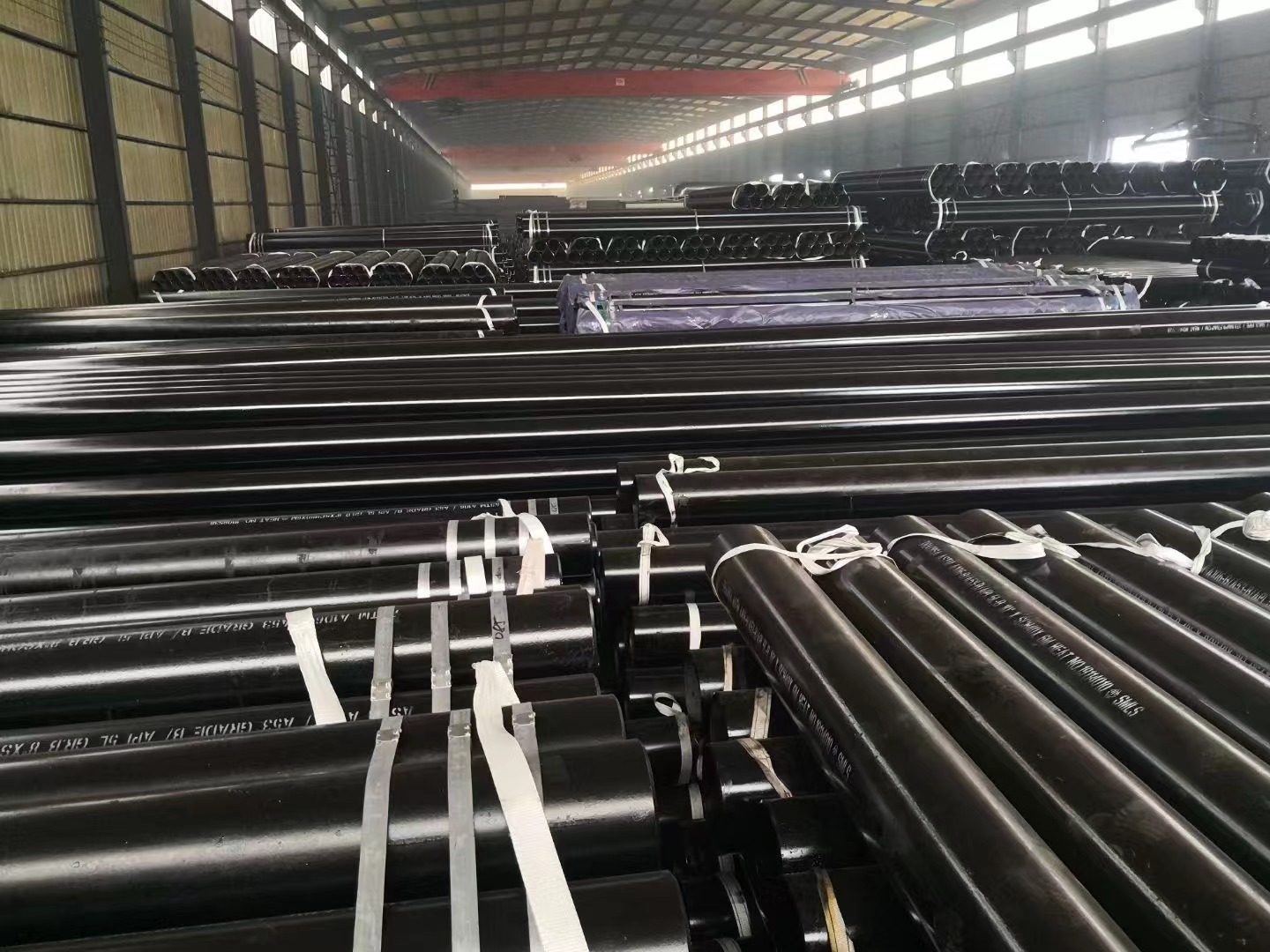

50mm flange

The 50mm flange is employed in a variety of settings. In plumbing, it might connect different sections of piping or join valves for systems that transport water or chemicals. In the oil and gas industry, 50mm flanges are vital for connecting pipelines that carry crude oil, natural gas, or refined products. The ability to create a secure and leak-tight seal is paramount in these applications, as any failure could result in costly environmental and safety hazards.

Moreover, 50mm flanges are common in HVAC systems for duct connections and air handling units. The flexibility in material choices means that engineers can select a flange type that best suits the operating temperature and pressure of the system involved.

Installation Considerations

When installing a 50mm flange, precise alignment and torque specifications are crucial to ensure a secure fit. The surface of the connecting pipes or equipment must be clean and free from debris to achieve an effective seal. It is also essential to use the correct type of gasket for the application, as this will enhance the overall performance of the connection.

When bolting the flange, it is important to follow a specific tightening sequence to evenly distribute pressure, reducing the likelihood of leakage. Regular inspections and maintenance can further prolong the lifespan of these connections.

Conclusion

In summary, the 50mm flange is an essential component in various industrial applications, providing strong and reliable connections across piping systems. Understanding its features, applications, and installation techniques is vital for anyone involved in engineering, construction, or facilities management. By selecting the right type of flange and implementing proper installation practices, stakeholders can ensure the integrity and efficiency of their systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024