-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 08, 2024 18:02 Back to list

6 150 blind flange

Understanding the 6% 150% Blind Flange Importance and Applications

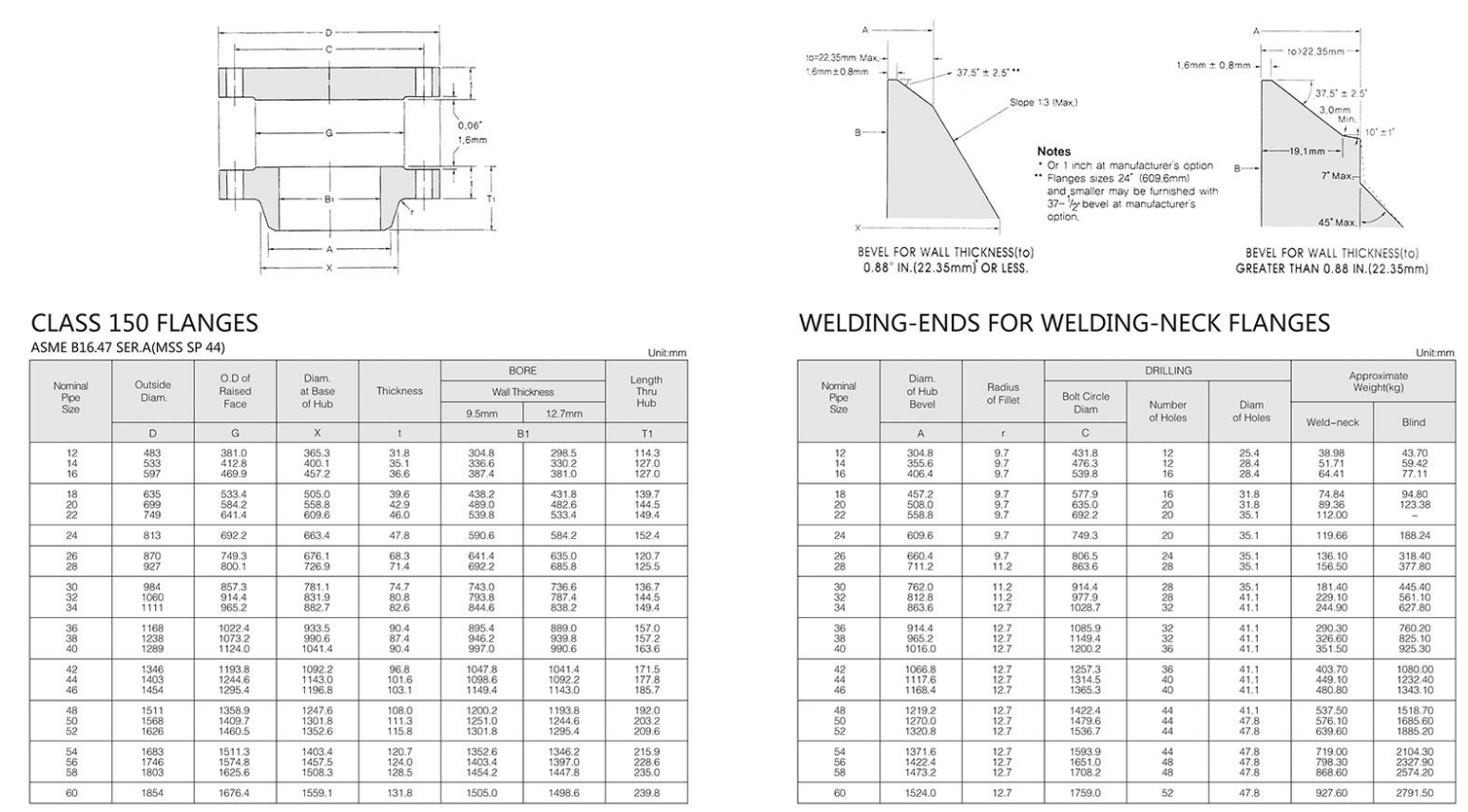

A blind flange is an essential component in various piping systems used in industries such as oil and gas, chemical processing, and water treatment. It is a type of flange that does not have a hole in the center, making it ideal for sealing the end of a piping system. Among the various specifications and standards governing flanges, the term 6% 150% blind flange often surfaces, denoting particular standards that can be critical for engineers, designers, and manufacturers.

What Does 6% 150% Mean?

In the context of flanges, 6% 150% generally refers to the pressure and temperature ratings of a blind flange based on the ANSI (American National Standards Institute) classifications. The 150 rating indicates that the flange can handle a maximum pressure of 150 psi (pounds per square inch) at a certain temperature. Furthermore, the 6% may refer to specific tolerance levels or dimensional specifications mandated by certain industry standards. Understanding these numbers is essential when selecting the appropriate blind flange for a specific application, ensuring the unit can withstand operational demands without failure.

Material Selection

Blind flanges are manufactured from a variety of materials, including carbon steel, stainless steel, and alloys, depending on the application requirements. For instance, carbon steel flanges are widely used in low-temperature and low-pressure applications due to their cost-efficiency, while stainless steel flanges provide durability and resistance to corrosion, making them ideal for more demanding environments. In cases where higher temperatures or aggressive chemicals are involved, specialty alloys might be necessary.

The material must be selected not only based on the temperature and pressure ratings but also on factors such as the chemical compatibility of the media flowing through the pipeline. Engineers often reference Material Safety Data Sheets (MSDS) and other compatibility charts to make informed decisions about material selection for a specific blind flange.

Importance of Proper Installation

6 150 blind flange

Installation of a blind flange is critical to ensure a leak-proof system. It is imperative to follow guidelines and best practices during the installation to avoid common pitfalls. This includes proper surface preparation, the use of correct gaskets, and ensuring that the bolt torque specification is adhered to. Misalignment during installation can lead to flange distortion, which may compromise the sealing performance.

Moreover, maintenance routines should include inspections of the blind flanges periodically to identify any signs of wear, corrosion, or leakage. Such practices ensure longevity and reliability in the piping system, ultimately reducing operational costs due to unexpected repairs or downtime.

Applications of Blind Flanges

Blind flanges find applications in various sectors. In the oil and gas industry, they are used to seal off the ends of pipelines during testing and to facilitate maintenance work. They serve as a barrier to ensure no fluid escapes, enabling safe handling of potentially hazardous materials. Similarly, in chemical processing facilities, blind flanges can isolate sections of a piping system during repairs or modifications without interrupting the entire operation.

In wastewater treatment plants, blind flanges can be utilized to prevent backflow or provide inspection points without needing an entire system shutdown. Their versatility and reliability make them a preferred choice among engineers and maintenance professionals.

Conclusion

In summary, the 6% 150% blind flange is a critical component in various piping systems, where precision in specifications, material selection, and careful installation plays a vital role in maintaining system integrity and safety. Understanding its characteristics and applications allows engineers and other stakeholders to make better decisions that can influence the efficiency and longevity of complex piping systems. As industries continue to evolve, knowledge of such components will remain essential for maintaining optimal operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024