-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 07, 2024 18:09 Back to list

Understanding the Importance of 6% Flange in Structural Engineering Applications

Understanding 6% Flange A Key Component in Engineering and Industry

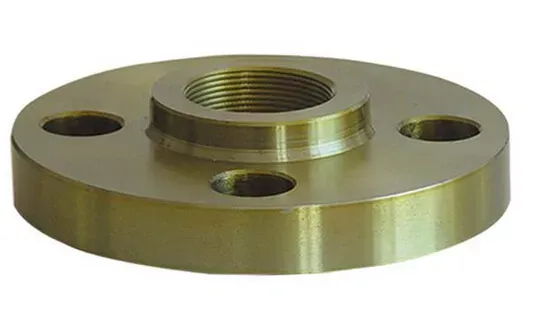

Flanges are an essential component in various engineering and industrial applications. They are used to join two pieces of equipment, piping, or machinery, creating a robust and reliable connection. Among the many types of flanges, the 6% flange has gained attention for its unique characteristics and advantages. This article delves into the features, applications, and benefits of the 6% flange, highlighting its significance in modern engineering.

What is a 6% Flange?

The term 6% flange generally refers to a specific dimensional ratio in the design of flanges, which is often associated with flanges that have a 6% thickness-to-diameter ratio. This particular ratio influences the flange's mechanical properties, durability, and suitability for various applications. A 6% flange can be either welded or bolted, depending on the requirements of the system in which it is used.

Flanges are typically categorized based on their shape, size, material, and pressure rating. The 6% flange can be made from various materials, including steel, stainless steel, plastic, and more, each of which affects the flange’s performance under different environmental conditions.

Advantages of 6% Flanges

1. Increased Strength One of the most notable benefits of the 6% flange design is its superior strength. The 6% ratio provides a balance between flexibility and rigidity, making it suitable for high-pressure applications where safety and reliability are paramount.

2. Enhanced Sealing Capability 6% flanges often feature a raised face or a flat face that facilitates better sealing when joined with gaskets. This is particularly important in systems that handle pressurized fluids or gases, as it minimizes the risk of leaks.

3. Ease of Installation The design of 6% flanges allows for easier alignment and connection, which can save both time and labor costs during installation. This feature is especially beneficial in complex industrial setups where precision is critical.

4. Corrosion Resistance Depending on the materials used, 6% flanges can be highly resistant to corrosion. This quality ensures longevity, even in harsh conditions, making them suitable for applications in chemical processing, oil and gas, and water treatment.

6 flange

5. Adaptability to Various Applications The versatility of 6% flanges means they can be employed in a wide range of industries, from construction and manufacturing to energy and aerospace. They can be tailored for specific applications, ensuring optimal performance.

Applications of 6% Flanges

6% flanges are utilized across numerous sectors due to their robust nature. Some common applications include

- Oil and Gas These flanges are integral in connecting pipelines and maintaining the integrity of systems that transport oil and gas. Their strength and leak-proof design are crucial in preventing spills and ensuring safety.

- Chemical Processing In facilities that handle corrosive substances, 6% flanges provide a reliable joining solution that minimizes the risk of chemical leaks and reactions between dissimilar materials.

- Water Treatment Water treatment plants often use 6% flanges to connect various components in filtration and distribution systems. Their corrosion-resistant properties are particularly valuable in this environment.

- Aerospace In the aerospace industry, the lightweight yet strong nature of 6% flanges makes them ideal for use in aircraft assemblies where weight reduction is a priority without compromising safety.

Conclusion

The 6% flange is a critical component in many industrial and engineering applications, offering strength, reliability, and versatility. Its specific design characteristics make it suitable for high-pressure scenarios and corrosive environments, adding to its appeal across multiple sectors. As industries continue to evolve and require more efficient and effective connection solutions, the 6% flange will likely remain a vital player in the field of mechanical engineering. Whether in oil and gas, chemical processing, water management, or aerospace, understanding and utilizing the advantages of 6% flanges is essential for enhancing performance and ensuring the safety and durability of various systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024