-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 19, 2024 18:37 Back to list

6 flange

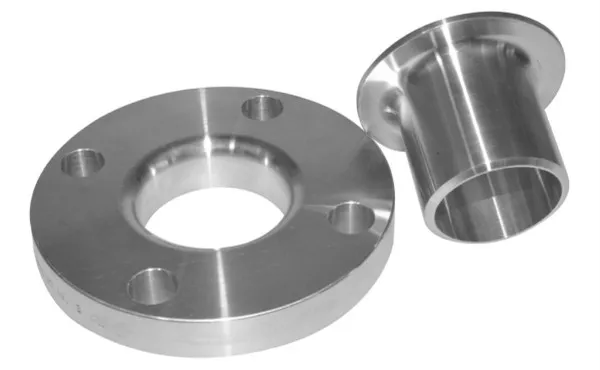

Understanding the 6% Flange Applications and Importance

In the world of engineering and construction, flanges play a crucial role in ensuring that various components of a system are securely joined together. Among the myriad of flange types, the 6% flange has emerged as a significant component due to its unique design and favorable properties. This article aims to explore the characteristics, applications, and importance of the 6% flange in various industries.

What is a 6% Flange?

The term 6% flange typically refers to a specific design wherein the flange provides a 6% increase in strength or load-bearing capacity compared to standard flanges within the same category. This enhancement can be attributed to various factors, including the material used, the design geometry, and the manufacturing processes involved. 6% flanges are often used in high-stress applications where traditional flanges may not suffice.

Characteristics of the 6% Flange

1. Material Composition The 6% flange is often made from high-strength materials such as carbon steel, stainless steel, or specialized alloys. These materials not only provide superior strength but also enhance corrosion resistance, making the flanges suitable for various environmental conditions.

2. Design Geometry The design of the 6% flange typically incorporates features that improve its performance under load. These may include thicker sections, reinforced edges, or geometric modifications that distribute stress more evenly across the flange.

3. Precision Engineering Given the critical role flanges play in maintaining the integrity of a system, the manufacturing of 6% flanges often adheres to strict tolerances and quality standards. This precision ensures that they fit seamlessly with other components and can withstand the necessary operating conditions without failure.

Applications of the 6% Flange

The versatility of the 6% flange makes it suitable for various applications across multiple industries

6 flange

1. Oil and Gas Industry In the oil and gas sector, flanges are commonly used to connect pipes and valves in high-pressure environments. The 6% flange's enhanced strength makes it ideal for use in critical applications such as offshore drilling and pipeline installations.

2. Water and Wastewater Treatment Flanges are integral in water treatment facilities, where they connect different components of the piping system. The durability and corrosion resistance of 6% flanges ensure they can withstand the harsh conditions often found in wastewater treatment processes.

3. Chemical Processing In chemical plants, flanges are used to connect vessels, reactors, and pipelines. The 6% flange can be designed to withstand aggressive chemicals, making it a reliable choice for ensuring the safety and efficiency of chemical processes.

4. Aerospace and Automotive In aerospace and automotive applications, the need for lightweight yet durable components is paramount. 6% flanges can be produced with advanced materials that provide strength without adding unnecessary weight, making them ideal for use in high-performance vehicles and aircraft.

Importance of the 6% Flange

The significance of the 6% flange lies in its ability to improve the safety, efficiency, and reliability of the systems in which it is used. By providing enhanced strength, these flanges help prevent leaks and failures that could lead to catastrophic events in critical applications. Moreover, their durability reduces maintenance costs and downtime, contributing to overall operational efficiency.

In addition, as industries increasingly focus on sustainability and reducing environmental impact, the ability to produce more reliable systems through the use of advanced components like the 6% flange becomes more critical. Their long service life and reduced failure rates align with these sustainability goals.

Conclusion

The 6% flange stands out as a vital component in numerous industries, combining strength, durability, and versatility. As engineering challenges continue to evolve, the demand for high-performance flanges, such as the 6% variety, will only increase. Engineers and designers must remain cognizant of these advancements to ensure optimal system performance and safety, confirming the lasting importance of the 6% flange in modern engineering.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024