-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 29, 2025 05:45 Back to list

EN10253 BUTT-WELDING FITTINGS Equal Tee/Reducing Tee

The skills required for 6G pipe welding are highly valued in industries such as oil and gas, construction, and shipbuilding. Mastering this intricate welding position can open doors to lucrative career opportunities. The 6G position, a challenging uphill and overhead task, involves welding a pipe fixed at a 45-degree angle, necessitating proficiency in various positional welds such as overhead, horizontal, and vertical. Here we delve into why 6G pipe welding stands as a benchmark for skill, quality, and industry compliance.

Trustworthiness in 6G pipe welding is crucial, as it directly affects the structural integrity and safety of the build. Industries view welders with a track record of delivering defect-free, structurally sound welds as invaluable. Trust is built over time, maintained through the consistent application of best practices and adherence to safety protocols. Experienced welders understand the implications of their work on overall project timelines and budgets, often viewed as partners in quality assurance due to their role in preventing costly reworks or potential failures. Companies investing in 6G pipe welding technologies further resonate in terms of trust. Innovations such as advanced arc welding machines with precise control settings, real-time monitoring tools, and safety-enhancing features demonstrate commitment to not only efficiency but also to safety and quality. Collaborations with equipment manufacturers ensure that welders have access to cutting-edge tools that aid in achieving superior outcomes. To conclude, mastering 6G pipe welding represents a pinnacle within the welding profession. It demands a harmonious blend of hands-on Experience, technical Expertise, recognized Authoritativeness, and inherent Trustworthiness. For organizations, employing skilled 6G welders and investing in supporting technologies reflects a dedication to maintaining the highest standards of quality and safety in their operations. As industries continue to evolve, these core attributes guarantee that 6G pipe welding remains an essential and respected craft worldwide.

Trustworthiness in 6G pipe welding is crucial, as it directly affects the structural integrity and safety of the build. Industries view welders with a track record of delivering defect-free, structurally sound welds as invaluable. Trust is built over time, maintained through the consistent application of best practices and adherence to safety protocols. Experienced welders understand the implications of their work on overall project timelines and budgets, often viewed as partners in quality assurance due to their role in preventing costly reworks or potential failures. Companies investing in 6G pipe welding technologies further resonate in terms of trust. Innovations such as advanced arc welding machines with precise control settings, real-time monitoring tools, and safety-enhancing features demonstrate commitment to not only efficiency but also to safety and quality. Collaborations with equipment manufacturers ensure that welders have access to cutting-edge tools that aid in achieving superior outcomes. To conclude, mastering 6G pipe welding represents a pinnacle within the welding profession. It demands a harmonious blend of hands-on Experience, technical Expertise, recognized Authoritativeness, and inherent Trustworthiness. For organizations, employing skilled 6G welders and investing in supporting technologies reflects a dedication to maintaining the highest standards of quality and safety in their operations. As industries continue to evolve, these core attributes guarantee that 6G pipe welding remains an essential and respected craft worldwide.

Latest news

-

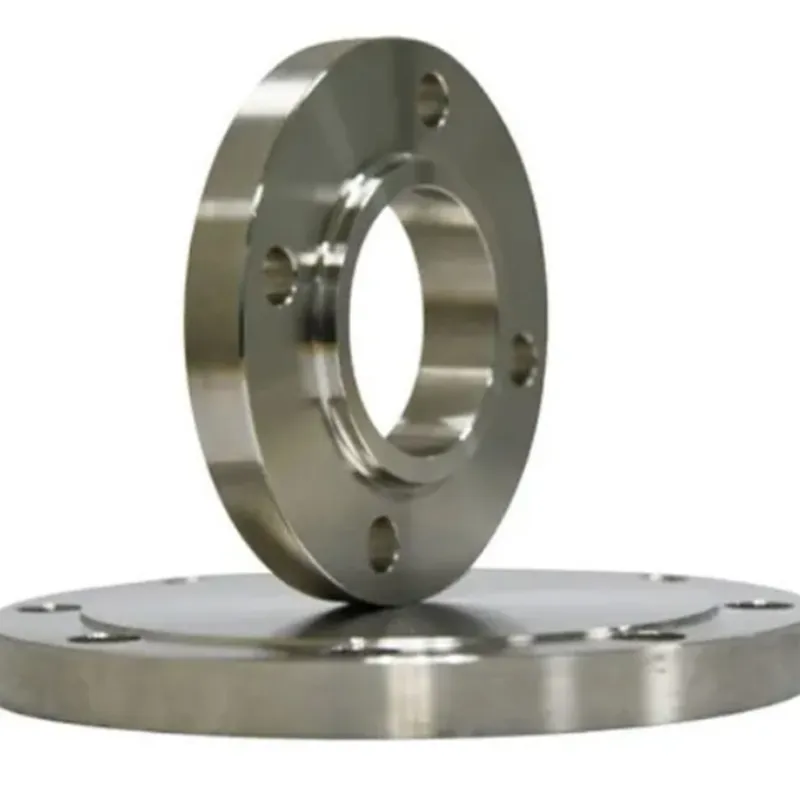

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024