-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 28, 2024 03:47 Back to list

Understanding 8% threaded pipe coupling for enhanced connection and efficiency in plumbing systems

Understanding 8% Threaded Pipe Coupling Its Importance and Applications

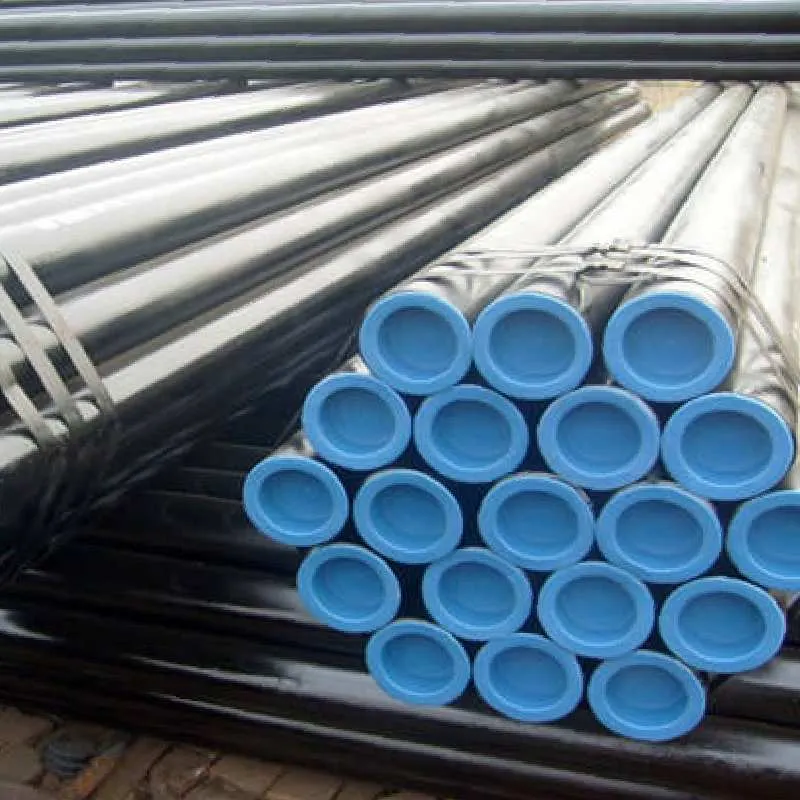

In the realm of plumbing and piping systems, the seamless connection between different components is crucial for maintaining an efficient and leak-proof network. One such essential component is the threaded pipe coupling, and among its various specifications, the 8% threaded pipe coupling stands out due to its unique features and applications.

A threaded pipe coupling is designed to connect two pipes or tubes in order to facilitate the transportation of fluids or gases. The 8% refers to a specific dimension or design characteristic that provides various advantages in installation and performance. Understanding the significance of this measurement can help in selecting the right coupling for specific projects.

Key Characteristics of 8% Threaded Pipe Coupling

1. Thread Design The 8% threaded pipe coupling features a unique thread design that enhances engagement between the connected pipes. This design ensures a tighter seal, which is critical in preventing leaks, especially in high-pressure environments.

2. Material Strength Typically manufactured from high-grade metals such as stainless steel or carbon steel, these couplings are built to withstand substantial pressure and temperature variations. The durability of the material ensures that the coupling can endure harsh conditions, making it suitable for both residential and industrial applications.

3. Ease of Installation The 8% threading allows for a more straightforward installation process. Since the threading grips the pipes firmly, it reduces the likelihood of misalignment during the installation, which can lead to potential failures or leaks. This benefit is particularly important for projects where time and efficiency are crucial.

8 threaded pipe coupling

Applications of 8% Threaded Pipe Coupling

The versatility of 8% threaded pipe couplings allows them to be employed in various applications, including

- Water Supply Systems Commonly used in municipal water piping, these couplings ensure that water is transported smoothly and without leaks. Their structural integrity makes them ideal for handling various pressures experienced in water distribution systems.

- Heating and Cooling Systems In HVAC systems, maintaining a leak-free system is essential for efficiency. 8% threaded couplings provide reliable connections between pipes transporting hot or cold fluids, ensuring that the systems operate optimally.

- Oil and Gas Industry The oil and gas sector relies heavily on robust piping systems to transport fuels and other chemicals. The strength and reliability of 8% threaded couplings make them a critical component in these high-stakes environments, where any failure can result in catastrophic outcomes.

Conclusion

In conclusion, the 8% threaded pipe coupling is an indispensable element in modern piping systems, offering a range of benefits that enhance the efficiency and reliability of fluid transport. Its unique thread design and material properties cater to a diverse range of applications, making it a preferred choice among engineers and contractors. Understanding its characteristics and applications can lead to more informed decisions in choosing the right components for plumbing and piping projects. As industries strive for greater efficiency and safety, investing in quality couplings like the 8% threaded variety will undoubtedly contribute to better performance and longevity of piping systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024