-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 13, 2024 16:32 Back to list

A Comprehensive Guide to DIN Flange

Flanges play a critical role in connecting pipes, valves, and other equipment in a variety of industrial applications. When it comes to ensuring the strength and reliability of these connections, DIN flanges offer a widely recognized standard for quality and performance. This guide will explore the different DIN flange types, help you choose the right DIN flange, provide insights into finding a reputable DIN flange manufacturer, and explain DIN flange sizes to meet your specific needs.

-

DIN2527 Blind Flange

-

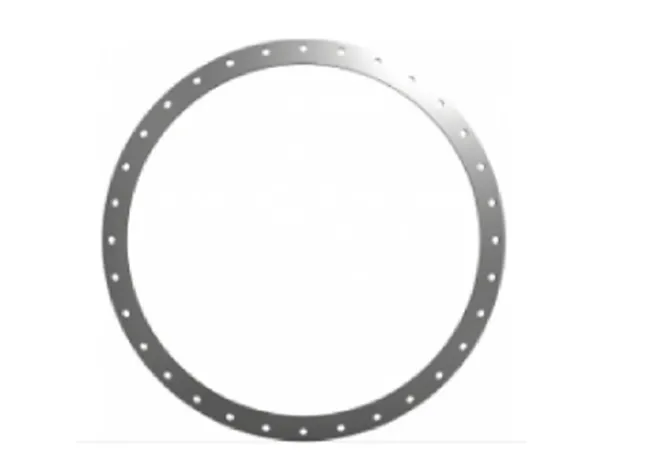

DIN86044 PLATE FLANGE

Understanding DIN Flange Types

DIN flanges adhere to standards set by the Deutsches Institut für Normung (DIN), a German organization that defines specifications for various industrial components. The standardization ensures compatibility, reliability, and ease of use across different systems. Here’s an overview of common DIN flange types:

DIN 2527 Flanges: These are commonly used for pipe connections in low-pressure applications. They feature a flat face and are suitable for a wide range of industrial uses.

DIN 2631-2638 Flanges: These are part of the DIN 2630 series, including various pressure ratings and sizes. They are used in applications requiring different pressure levels and temperatures.

DIN 2543-2547 Flanges: These are used for medium-pressure applications and come with a raised face. They are often chosen for their durability and ability to handle moderate pressures.

DIN 2512 Flanges: These flanges are typically used for high-pressure applications and feature a thick design for enhanced strength. They are suitable for demanding environments where robust connections are essential.

DIN 2573 Flanges: These are designed for high-pressure systems and are available in various sizes and pressure ratings. They are known for their strong construction and reliability.

DIN 2861-2868 Flanges: These flanges are used for specific pressure and temperature requirements. They include a range of pressure ratings and sizes, catering to various industrial needs.

Choosing the Right DIN Flange

Selecting the appropriate DIN flange is crucial for ensuring the success and reliability of your piping system. Here are key factors to consider:

Application Requirements: Determine the pressure, temperature, and material requirements for your application. Different DIN flange types are designed for specific conditions, so choose one that matches your needs.

Material Compatibility: Ensure that the flange material is compatible with the fluids or gases in your system. Common materials include carbon steel, stainless steel, and alloy steel.

Size and Pressure Rating: Choose a flange that matches the size of your pipes and meets the pressure rating required for your application. DIN flange sizes vary, so ensure the flange fits properly with your system components.

Face Type: Flanges come with different face types, such as flat face, raised face, or ring-type joint. Select the face type that aligns with your sealing and pressure requirements.

Finding the Best DIN Flange Manufacturer

To ensure you receive high-quality DIN flanges, partnering with a reputable DIN flange manufacturer is essential. Here’s how to find the right manufacturer:

Reputation and Experience: Choose a manufacturer with a proven track record and extensive experience in producing DIN flanges. Experienced manufacturers are more likely to offer reliable and high-quality products.

Product Range: Ensure the manufacturer offers a comprehensive range of DIN flange types and sizes. This allows you to find the right flange for your specific requirements.

Quality Control: Look for manufacturers that adhere to strict quality control standards and certifications. This ensures that the flanges meet industry specifications and performance criteria.

Customization Capabilities: If you need custom flanges, choose a manufacturer that offers customization options. This flexibility is valuable for meeting unique project requirements.

Pricing and Delivery: Compare pricing and check the manufacturer’s delivery schedules. Reliable manufacturers should offer competitive pricing and ensure timely delivery of your orders.

Customer Support: Good customer service is essential for addressing any issues or questions. Choose a manufacturer that provides comprehensive support throughout the purchasing process.

Understanding DIN Flange Sizes

DIN flange sizes are defined to ensure compatibility and proper fit within various piping systems. Here’s an overview of what to consider:

Standard Sizes: DIN flanges come in a range of standard sizes to match different pipe dimensions. These sizes are defined by the DIN standards and are designed to fit seamlessly with other components.

Pressure Ratings: Different DIN flange types have varying pressure ratings. Ensure the flange size you choose can handle the pressure requirements of your system.

Flange Dimensions: Check the flange dimensions, including diameter, thickness, and bolt hole pattern, to ensure they match your piping system and equipment.

Material Considerations: The size of the flange should be compatible with the material used in your piping system. Different materials may have specific size requirements.

Understanding DIN flange types, selecting the right DIN flange, and finding a reputable DIN flange manufacturer are critical for ensuring the success of your piping projects. By considering factors such as application requirements, material compatibility, and flange sizes, you can make informed decisions that enhance the reliability and efficiency of your systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024