-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 04, 2024 10:52 Back to list

all flange types

All Flange Types An Overview

Flanges play a crucial role in various industries, especially in piping systems, by providing a reliable method to connect pipes, valves, pumps, and other equipment. They facilitate easy disassembly and maintenance without the need to cut pipes, making them essential components in both industrial and residential applications. This article explores the different types of flanges, their applications, and the materials from which they are made.

1. Types of Flanges

Flanges come in various types, each designed for specific applications and environments. Understanding these can aid in selecting the appropriate flange for your needs.

- Weld Neck Flange This flange type has a long neck that connects to the pipe through welding. Its design helps to distribute stress and is widely used in high-pressure applications.

- Slip-On Flange Designed to slip over the pipe, this flange is easy to install and is suitable for low-pressure applications. However, it may not be the best choice for high-stress situations as it doesn’t provide as much support as other types.

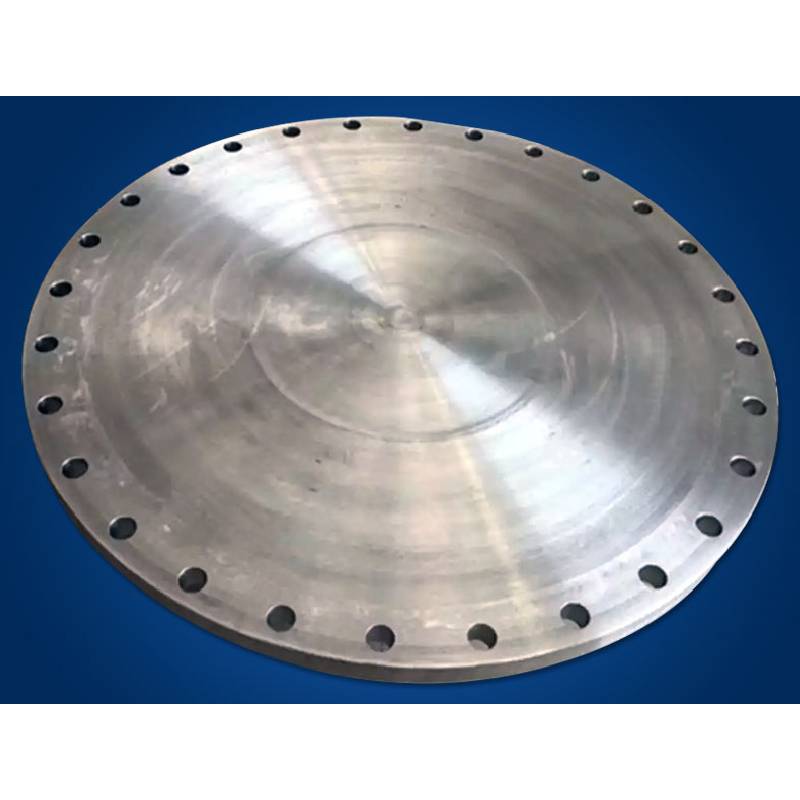

- Blind Flange As the name suggests, a blind flange doesn’t have a hole in the center. It is used to seal the end of a piping system, preventing the flow of liquids or gases.

- Threaded Flange This flange has internal threads that allow it to screw onto the pipe, making it ideal for applications where welding is not feasible. It works best in lower-pressure systems.

- Lap Joint Flange Used with a stub end, a lap joint flange can be easily assembled and disassembled, making it a popular choice for applications requiring regular maintenance.

- Socket Weld Flange This type features a socket into which the pipe is inserted and welded. It is used primarily in small diameters and high-pressure applications.

- Spectacle Blind Flange A unique design that includes a spectacle or angled shape, allowing the operator to choose between a closed (blind) or open (flanged) condition. This type is often used in large piping systems.

2. Materials Used

Flanges can be fabricated from various materials depending on the application.

all flange types

- Carbon Steel A common choice due to its strength and durability, carbon steel flanges are widely used in various industries, from oil and gas to water treatment.

- Stainless Steel Known for its corrosion resistance, stainless steel flanges are ideal for environments that demand high hygiene levels, such as food and beverage processing

.- Alloy Steel These flanges are designed for high-temperature and high-strength applications. They often contain elements like chromium and molybdenum to enhance their properties.

- Plastic Flanges For certain applications, especially in chemical processing, plastic flanges may be used to resist corrosion and prevent contamination.

3. Applications

Flanges are used in a variety of industries.

- Oil and Gas Given the high-pressure nature of this industry, robust flange types like weld neck and socket weld flanges are commonly used.

- Chemical Processing Here, corrosion-resistant materials like stainless steel and plastic flanges are preferred, ensuring safety and reliability in the transportation of chemicals.

- Waterworks Flanges are vital in water treatment plants, with blind flanges often used to block off sections for repairs or maintenance.

- Construction and Manufacturing Flanges are essential in building infrastructure, allowing for flexible designs in piping systems.

4. Conclusion

Understanding the different types of flanges, their materials, and applications is essential for anyone involved in plumbing, construction, or engineering. From ensuring the integrity of a piping system to facilitating easy maintenance, flanges are indispensable components in various industrial setups. By selecting the appropriate flange type for specific applications, one can maintain efficiency, safety, and reliability in their operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024