-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 21, 2024 19:20 Back to list

ansi 150lb

Understanding ANSI 150 LB Flanges A Comprehensive Overview

ANSI 150 lb flanges are a critical component in the piping industry, facilitating various applications across numerous sectors, including oil and gas, water treatment, and chemical processing. The term “ANSI” refers to the American National Standards Institute, which sets the standards for flanges and piping components to ensure compatibility, safety, and performance.

Flange Classification

The “150 lb” designation indicates the pressure rating of the flange, specifically designed to operate safely at a maximum pressure of 150 psi (pounds per square inch) at ambient temperatures. ANSI 150 lb flanges are categorized as Class 150 and are made of various materials, including carbon steel, stainless steel, and other alloys, each chosen based on the specific requirements of the application, such as temperature, pressure, and corrosion resistance.

Design and Dimensions

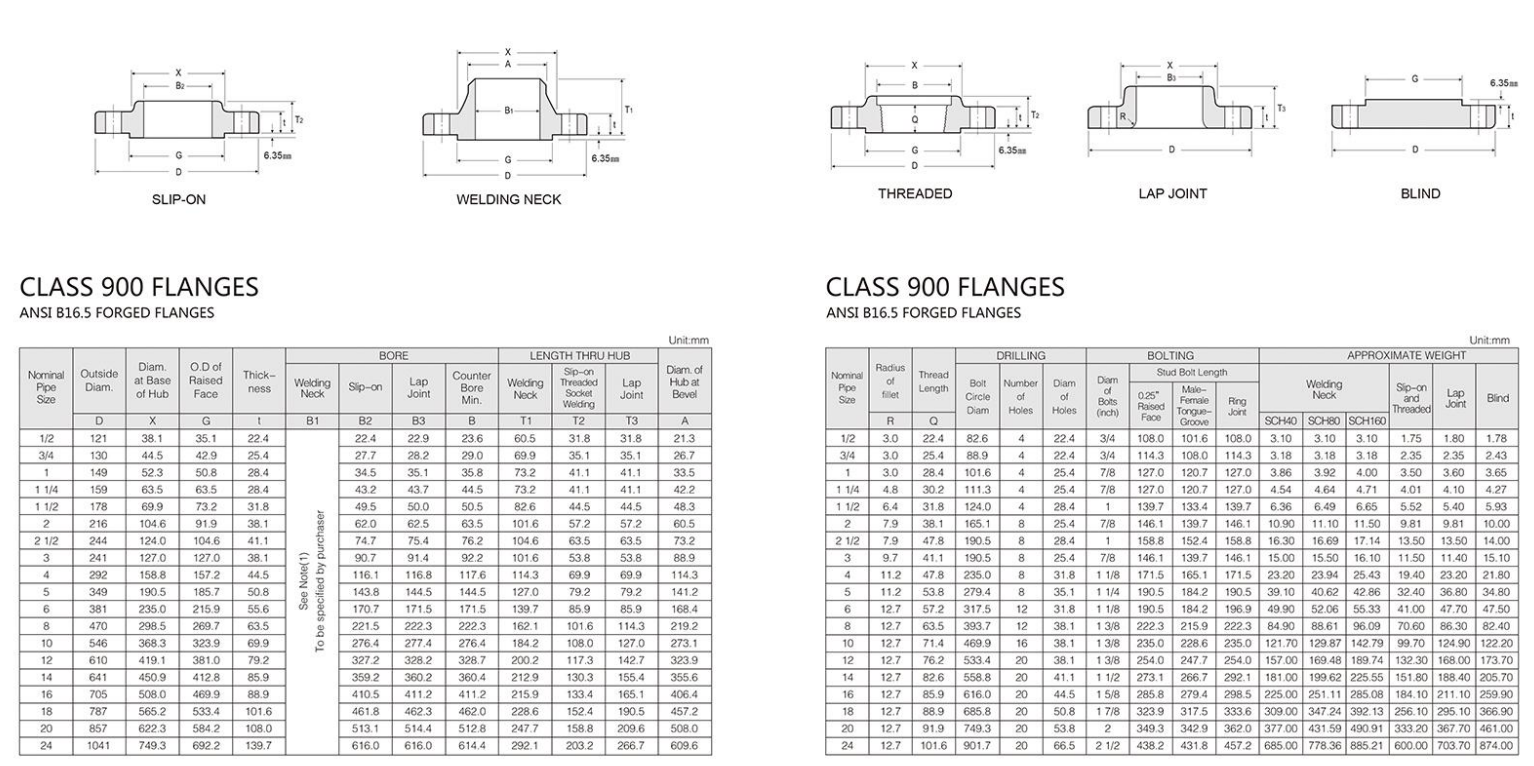

ANSI 150 lb flanges conform to established dimensions and mechanical properties as outlined in ANSI/ASME B16.5 standards. These standards specify dimensions such as outer diameter, bolt hole size, and thickness for different flange types, including weld neck, slip-on, blind, and threaded flanges. The design is crucial for ensuring proper alignment, secure sealing, and reliable performance under operational conditions.

ansi 150lb

Applications

Due to their robust design and pressure-handling capabilities, ANSI 150 lb flanges are widely utilized in various applications. They can be found in pipeline systems carrying water, gas, and other fluids. In the oil and gas industry, these flanges are often used in drilling and refining operations, where they connect pipes, valves, pumps, and other equipment. The chemical processing industry also employs ANSI 150 lb flanges due to their suitability for handling various chemical substances safely.

Installation and Maintenance

Proper installation and maintenance of ANSI 150 lb flanges are essential to ensure operational efficiency and safety. Flanges must be aligned correctly before tightening, and it’s crucial to use the appropriate gaskets and bolt configurations to create a tight seal that prevents leaks. Regular inspections and maintenance help identify issues like corrosion or wear, extending the flange's life and preventing costly downtimes in industrial operations.

Conclusion

In summary, ANSI 150 lb flanges are a vital element of modern piping systems, providing the necessary pressure ratings and dimensional standards for various industrial applications. Their design adheres to strict ANSI/ASME standards, ensuring compatibility and reliability. Understanding their function, applications, and maintenance requirements is essential for engineers, technicians, and professionals involved in the design, installation, and operation of piping systems. As industries continue to evolve, the significance of ANSI 150 lb flanges remains steadfast, underpinning the infrastructure that facilitates the flow of essential resources in our society.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024