-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 14, 2024 16:05 Back to list

Understanding ANSI Slip-On Flanges and Their Applications in Mechanical Systems

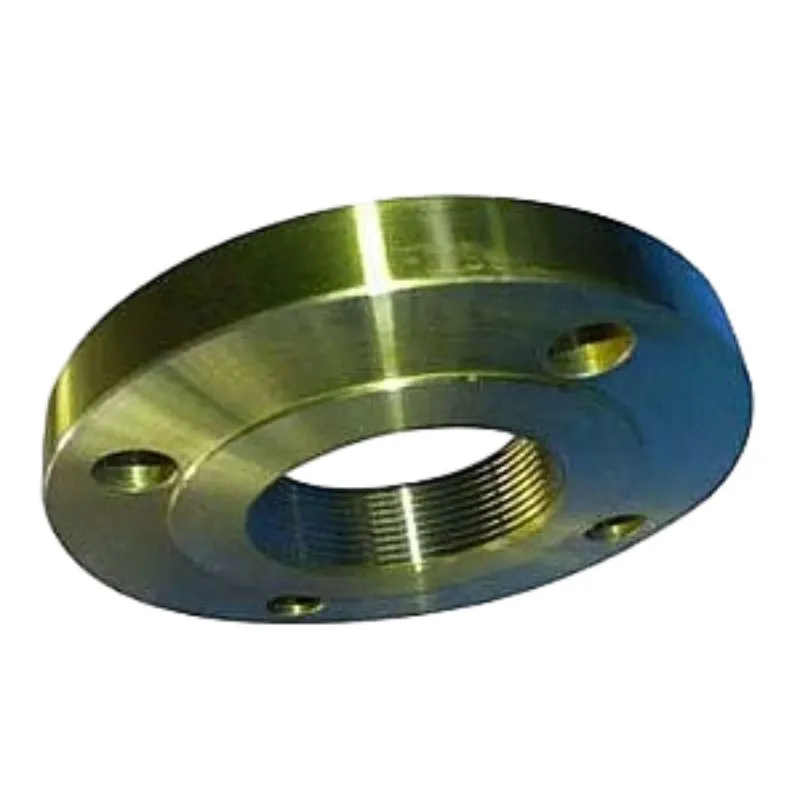

Understanding ANSI Slip-On Flanges A Comprehensive Guide

Flanges are essential components in various piping systems, serving as the connection point between different pipes, valves, and machinery. Among the various types of flanges available, the ANSI slip-on flange is one of the most popular choices in industrial applications. This article aims to explore the characteristics, advantages, applications, and installation of ANSI slip-on flanges, providing a complete overview for engineers and technicians.

What is an ANSI Slip-On Flange?

The ANSI (American National Standards Institute) slip-on flange is designed to fit over the end of a pipe, allowing for easy alignment and welding. The flange has a slightly larger internal diameter than the outer diameter of the pipe, facilitating a slip-on installation. It is commonly manufactured from various materials, including carbon steel, stainless steel, and alloys, ensuring compatibility with the specific requirements of different projects.

Specifications and Dimensions

ANSI slip-on flanges adhere to specific dimensional standards outlined by the ANSI/ASME B16.5 and B16.47 standards. They are available in various pressure ratings, typically classified as Class 150, Class 300, Class 600, and so forth. These classes refer to the maximum pressure and temperature conditions that the flange can withstand. The size of slip-on flanges can range from 1/2 inch to 60 inches in diameter, making them versatile for many applications.

Advantages of ANSI Slip-On Flanges

1. Ease of Installation One of the most significant benefits of slip-on flanges is their simplicity in installation. They can be positioned over the pipe and welded, saving time and effort during the installation process.

2. Cost-Effectiveness Slip-on flanges generally require less material than other flange types, such as welded neck flanges. This cost-efficient design translates into lower expenses for manufacturers and installers.

3. Alignment The slip-on design allows for better alignment with the pipe. This is particularly beneficial in environments where precision is crucial, as it minimizes the risk of misalignment during assembly.

ansi slip on flange

4. Versatility Due to their compatibility with various materials and sizes, ANSI slip-on flanges can be used across different industries, including oil and gas, water treatment, and chemical processing.

Applications

ANSI slip-on flanges are commonly used in numerous applications due to their versatility. They are frequently found in

- Pipelines Connecting different sections of pipelines in a wide array of industries. - Chemical Plants Providing reliable joints in high-pressure systems. - HVAC Systems Ensuring durable connections in heating, ventilation, and air conditioning systems. - Waterworks Facilitating connections in municipal water supply systems.

Installation Process

The installation of ANSI slip-on flanges is relatively straightforward. The following steps outline the typical process

1. Preparation Ensure that both the pipe end and the flange surface are clean and free of debris. 2. Alignment Place the flange over the pipe, ensuring it is correctly aligned for welding. 3. Welding Perform a fillet weld around the circumference of the flange to secure it to the pipe. Depending on the application, additional welding may be necessary for increased strength. 4. Testing After installation, conduct appropriate pressure tests to ensure that the joint is secure and leak-free.

Conclusion

ANSI slip-on flanges represent a reliable and practical choice for a broad spectrum of piping applications. Their ease of installation, cost-effectiveness, and versatility make them a preferred option among engineers and technicians. Understanding the specifications, advantages, and proper installation techniques for ANSI slip-on flanges can significantly contribute to the efficiency and reliability of industrial piping systems. Whether in oil refineries, chemical plants, or water treatment facilities, these flanges continue to play a crucial role in maintaining the integrity of piping systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024