-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 24, 2024 05:10 Back to list

ansi split flange

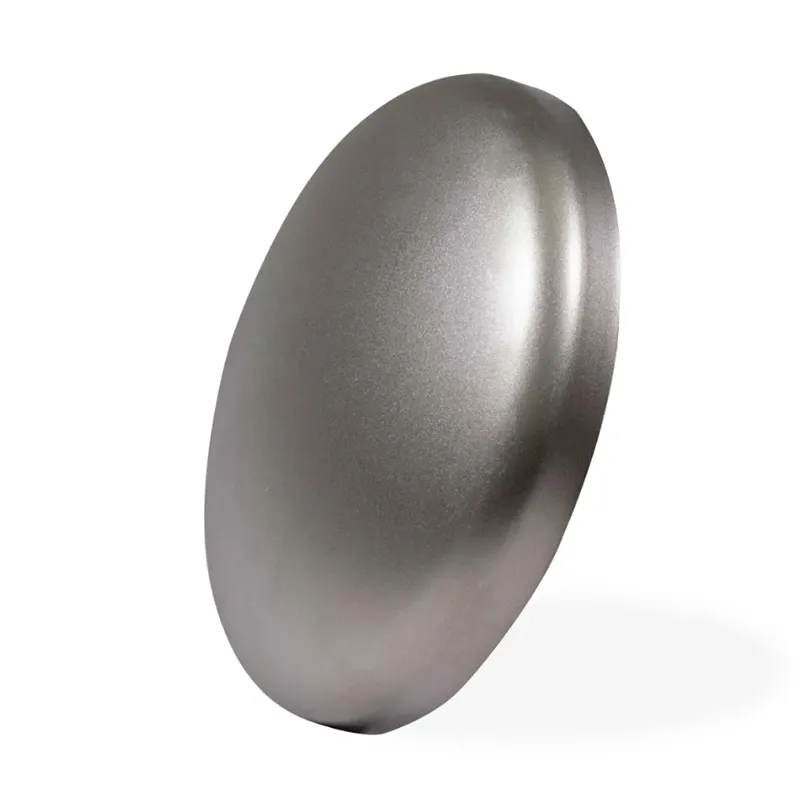

Understanding ANSI Split Flanges An In-Depth Overview

In the world of piping and industrial applications, ANSI split flanges are a vital component designed to provide efficient and reliable connections. These flanges are particularly favored in systems where disassembly and reassembly are frequent, as they simplify the maintenance process while ensuring a secure attachment.

What are ANSI Split Flanges?

ANSI split flanges refer to a specific type of flange that is designed in accordance with the American National Standards Institute (ANSI) specifications. They are characterized by their unique split design, which allows for easy installation and removal without the need to disconnect the entire pipe system. Typically made from materials such as carbon steel, stainless steel, and other alloys, ANSI split flanges are versatile and suitable for various applications, including oil and gas, water distribution, and chemical processing.

Construction and Design

The primary distinction of ANSI split flanges is their divided nature. Unlike traditional flanges that are solid and require welding or one-piece installation, split flanges consist of two halves that can be bolted together. This design allows for significant flexibility

1. Ease of Installation Installation is simplified because the split flanges can be mounted around existing pipes without having to slide them over the ends.

2. Versatility ANSI split flanges can accommodate different pipe sizes and types, making them suitable for various industrial applications.

3. Accessibility These flanges enhance access to the piping system for inspection, cleaning, or modification, reducing downtime during maintenance.

Applications of ANSI Split Flanges

ANSI split flanges are used in a variety of applications across multiple industries, including

- Oil and Gas In the extraction and transportation of oil and gas, split flanges are used to connect pipes and equipment, where frequent maintenance and changes are necessary.

- Water Treatment Water treatment plants utilize split flanges for easy access to piping systems handling chemical treatments, filtration, and distribution

.ansi split flange

- Chemical Processing Split flanges play a crucial role in chemical processing operations where certain sections of pipes may require regular inspection or cleaning.

Benefits of Using ANSI Split Flanges

1. Maintenance-Friendly The design allows for quick disassembly, enabling easier maintenance, repair, and replacement of piping components without disturbing the entire system.

2. Cost-Effective By minimizing the labor and time required for disassembly, ANSI split flanges can lead to significant cost savings over the life of a pipeline system.

3. Reduced Risk of Damage When installing or removing piping sections, the split design reduces the likelihood of damaging other components, as it allows for more controlled and precise manipulation.

4. Leak Prevention The secure connection provided by ANSI split flanges helps to prevent leaks, enhancing the overall safety and integrity of the piping system.

Considerations When Choosing ANSI Split Flanges

When selecting ANSI split flanges for your specific application, several factors should be considered

- Material Compatibility Ensure that the flange material is compatible with the fluids being transported to prevent corrosion and degradation.

- Size and Pressure Rating Choose the appropriate size and pressure rating, as different applications may require different specifications.

- Standards Compliance Verify that the split flanges meet relevant ANSI and industry standards to ensure safety and reliability.

Conclusion

ANSI split flanges offer a unique solution for piping systems requiring regular maintenance and flexibility. Their design enhances accessibility and facilitates quick assembly and disassembly, making them invaluable in industries such as oil and gas, water treatment, and chemical processing. By understanding the benefits and applications of ANSI split flanges, engineers and operators can make informed decisions that contribute to the efficiency and longevity of their piping systems. Embracing such components ensures that the operational needs are met without compromising on safety and reliability.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024