-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 31, 2024 03:11 Back to list

ansi threaded flange

The ANSI Threaded Flange An Overview

The ANSI threaded flange, a crucial component in piping systems, plays an essential role in ensuring a reliable and leak-proof connection between various pipes and equipment. Understanding its design, applications, and advantages is essential for engineers and technicians involved in industrial processes.

What is an ANSI Threaded Flange?

The ANSI (American National Standards Institute) threaded flange is a type of pipe flange that is designed to be screwed onto the end of a pipe, facilitating a robust connection. Unlike welded or slip-on flanges, threaded flanges do not require welding to create a secure attachment. This feature makes them particularly advantageous in situations where welding is impractical or undesirable, such as in high-pressure environments or when working with materials that may be sensitive to heat.

Design Characteristics

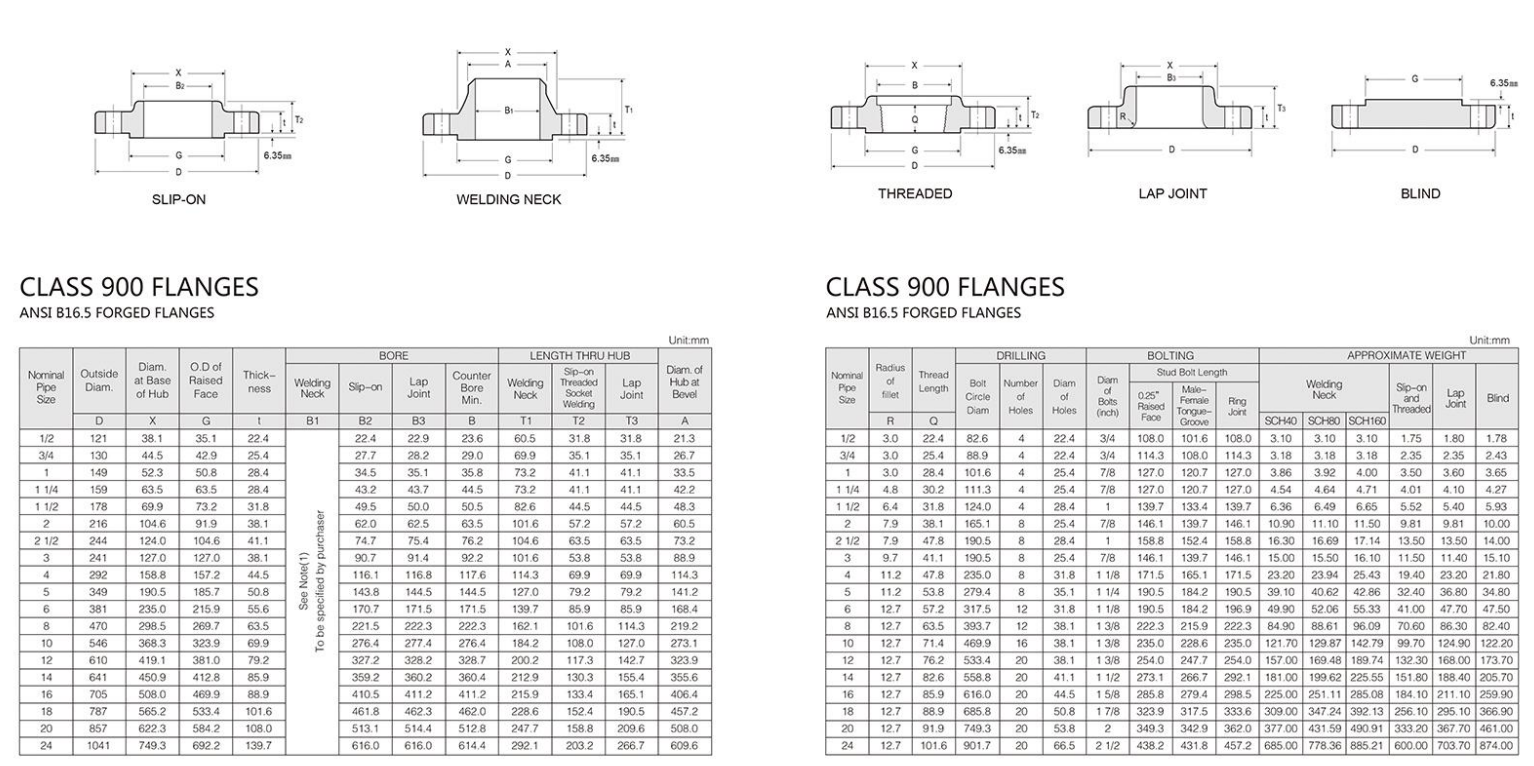

ANSI threaded flanges are manufactured to specific dimensional standards, predominantly outlined in the ANSI/ASME B16.5 standard. These standards define various parameters, including the flange dimensions, pressure ratings, and material specifications. Threaded flanges are typically available in a range of materials such as stainless steel, carbon steel, and other alloys, making them suitable for diverse applications, from chemical processing to oil and gas production.

One notable aspect of threaded flanges is the use of a truncated or flat face, designed to accommodate a gasket. This setup ensures a proper seal when the flange is assembled with a corresponding pipe or fitting. The design also allows for a high degree of flexibility in terms of installation and maintenance, as they can be easily removed and replaced.

Applications

ansi threaded flange

ANSI threaded flanges are widely utilized across numerous industries, including

1. Oil and Gas Industry Their resistance to corrosive substances and high pressures makes them ideal for oil and gas pipelines. 2. Chemical Processing In chemical plants, ANSI threaded flanges are used to connect pipes that handle various hazardous materials. 3. Water Treatment These flanges are often found in water treatment facilities due to their ability to withstand varying temperature and pressure conditions. 4. HVAC Systems Threaded flanges are also employed in heating, ventilation, and air conditioning systems to ensure secure connections.

Advantages of ANSI Threaded Flanges

The popularity of ANSI threaded flanges can be attributed to several key advantages

1. Ease of Installation Their screw-on design allows for straightforward assembly and disassembly, reducing labor costs and installation time. 2. Versatility Available in various sizes and materials, they can be adapted to suit specific requirements, making them suitable for a broad range of applications. 3. Reduced Risk of Damage Since they do not require welding, threaded flanges minimize the risk of heat damage to pipes or fittings, preserving the integrity of sensitive materials. 4. Cost-Effectiveness The installation and maintenance benefits of threaded flanges can result in overall cost savings for projects, making them an economically viable option.

Conclusion

In summary, ANSI threaded flanges are a vital component in many industrial applications, offering a reliable and efficient method for connecting pipes and equipment. Their unique design, combined with ease of installation, versatility, and cost-effectiveness, has solidified their position as an indispensable element in modern piping systems. Understanding their characteristics and applications enables professionals to make informed decisions that enhance the performance and reliability of their systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024