-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 07, 2024 04:45 Back to list

api 5l psl2 x52

Exploring the API 5L PSL2 X52 Understanding the Standards for Line Pipes

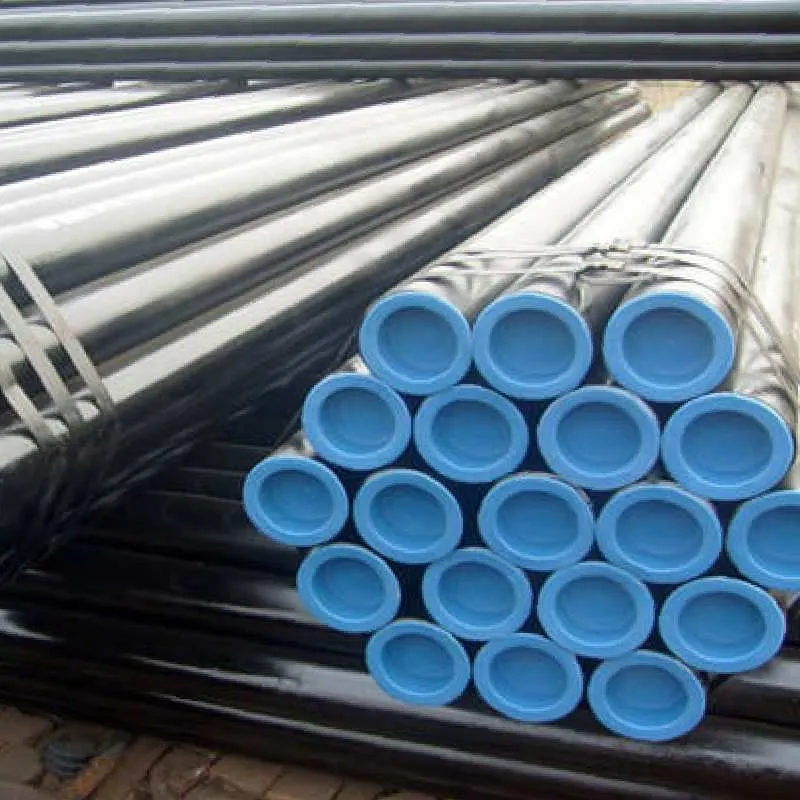

The API 5L standard, developed by the American Petroleum Institute, outlines the specifications for line pipes used in the transportation of oil, gas, and water in pipelines. Among the various grades defined by this standard, the PSL2 X52 designation has gained prominence in the industry due to its durability and reliability. This article delves into the characteristics, applications, and significance of the API 5L PSL2 X52 line pipe.

Understanding API 5L PSL2 X52

The API 5L specification is divided into two product specification levels PSL1 and PSL2. The “X52” in PSL2 X52 denotes the minimum yield strength of the pipe, which is 52,000 psi (pounds per square inch). This specific grade is designed to meet the mechanical and chemical property requirements set forth in the API standard, ensuring it can withstand high pressure and harsh conditions typical in oil and gas transportation.

PSL2 pipes have stricter requirements compared to PSL1, which often leads to improved toughness and corrosion resistance. They undergo additional testing methods, including non-destructive examination (NDE) and additional impact tests, making PSL2 X52 an optimal choice for more demanding applications.

Mechanical Properties

The mechanical properties of API 5L PSL2 X52 include a minimum yield strength of 52,000 psi and a minimum tensile strength of 65,000 psi. The pipe typically features good weldability and high resistance to stress corrosion cracking, important attributes in the harsh environments where these pipes are often deployed.

api 5l psl2 x52

Furthermore, PSL2 X52 has enhanced toughness, which is critical for pipelines operating in extreme temperatures. This ensures that they remain intact under challenging conditions, thereby reducing the likelihood of leaks or failures that can have catastrophic consequences.

Applications

The API 5L PSL2 X52 line pipes are extensively used in various sectors of the oil and gas industry, particularly in the construction of pipelines for transporting crude oil, natural gas, and refined products. Additionally, they are increasingly being utilized in water supply systems and in the structural applications of different engineering projects due to their strength and durability.

The versatility of X52 makes it suitable not just for onshore applications but also for offshore pipelines where the risk from corrosive elements is higher. The ability to withstand external pressures and mechanical stresses, combined with its resistance to various corrosive environments, underlines its significance in modern pipeline design.

Conclusion

In summary, API 5L PSL2 X52 represents a vital standard in the field of pipe manufacturing and is integral to the effective transportation of essential resources like oil and gas. Its enhanced mechanical properties, rigorous testing requirements, and broad application range highlight its importance in ensuring operational safety and reliability. As industries continue to evolve, the significance of high-quality materials such as API 5L PSL2 X52 will remain paramount in meeting the challenges of the future.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024