-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 05, 2024 21:01 Back to list

api 5l x42 pipe specification

Understanding the API 5L X42 Pipe Specification

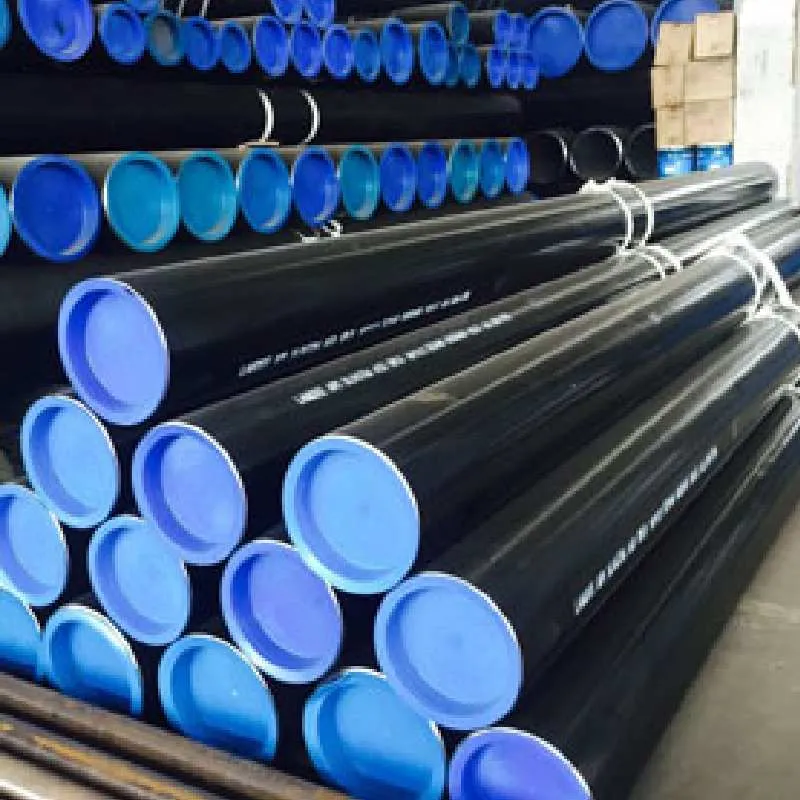

The API 5L X42 pipe specification is a critical standard set forth by the American Petroleum Institute (API) specifically designed for the oil and gas industry. This specification is essential for the construction and operation of pipelines that transport oil, gas, and other fluids. It ensures that materials and manufacturing processes meet stringent quality and performance requirements, enhancing safety and reliability in pipeline operations.

Overview of API 5L Specification

API 5L refers to the specification for line pipe, which includes carbon steel pipes that are used for the transmission of oil, gas, and water in various pipelines. The X in X42 denotes the yield strength of the pipe; in this case, the X42 indicates a minimum yield strength of 42,000 psi (290 MPa). This yield strength makes it suitable for high-pressure applications, a common requirement in oil and gas transport.

The specification provides detailed guidelines on the pipe material, manufacturing process, testing methods, and permissible defects. It covers both welded and seamless pipe production and specifies various grades of steel that can be used, including but not limited to X42, X52, and X60, among others.

Manufacturing Process

The manufacturing process for API 5L X42 pipes typically involves two primary methods seamless and welded. Seamless pipes are made by extruding steel billets, resulting in a pipe with a uniform wall thickness and enhanced mechanical properties. On the other hand, welded pipes are produced by rolling flat steel plates and welding them into a cylindrical shape. Both methods have their advantages seamless pipes generally offer better strength, while welded pipes are often more cost-effective for larger diameters.

Chemical Composition and Mechanical Properties

The chemical composition of API 5L X42 pipe is critical in achieving the required mechanical properties and ensuring compatibility with the substances transported. The standard specifies limits for various elements, including carbon (C), manganese (Mn), phosphorus (P), sulfur (S), and copper (Cu), among others. For example, the maximum carbon content is typically capped at 0.26%, which contributes to better weldability and ductility.

api 5l x42 pipe specification

In addition to the yield strength, the API 5L X42 specification also outlines requirements for tensile strength, elongation, and hardness. These mechanical properties ensure that the pipe can withstand operational stresses and environmental conditions, such as temperature fluctuations and corrosive substances.

Testing Standards

To ensure that the pipes meet the required specifications, various testing methods are employed throughout the manufacturing process. These tests include non-destructive examinations such as ultrasonic testing (UT) and radiographic testing (RT) to identify any internal or external defects. Mechanical tests such as tension tests and impact tests verify the pipe's strength and toughness, leaving no room for error in high-stakes operations like those in the oil and gas sector.

Applications and Industry Relevance

API 5L X42 pipes are widely used in numerous applications, including

1. Oil and Gas Transportation Essential for transferring crude oil, natural gas, and refined products over long distances. 2. Water Transmission Used in water supply lines where high-pressure requirements exist.

3. Industrial Fluid Transport Suitable for transporting various industrial fluids in chemical and processing plants.

The ANSI and API standards provide a universally accepted framework that guarantees quality and safety in pipeline construction and operation. Compliance with API 5L X42 not only facilitates regulatory adherence but also boosts stakeholder confidence in the integrity of pipeline infrastructures.

In conclusion, adhering to API 5L X42 pipe specifications is foundational for the energy sector, where safety, quality, and performance are paramount. Understanding these specifications enables engineers and contractors to make informed decisions, ensuring the effectiveness and longevity of pipeline systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024