-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 19, 2024 15:39 Back to list

api5lx52 specification

The API 5L X52 specification is a critical standard developed by the American Petroleum Institute (API) that governs the production and quality assurance of line pipe used in the transportation of gas, water, and oil. This specification is essential for ensuring reliability and safety in the pipeline industry, particularly for oil and gas operations that require durable and high-strength materials.

.

The manufacturing process for API 5L X52 pipes involves stringent quality control measures to ensure that they meet the defined specifications. This includes rigorous testing for mechanical properties, chemical composition, and other critical performance indicators. The pipes are produced using both seamless and welded construction methods, catering to different operational requirements. Seamless pipes are often preferred for their superior pressure-handling capabilities, while welded pipes provide economic advantages in large-scale projects.

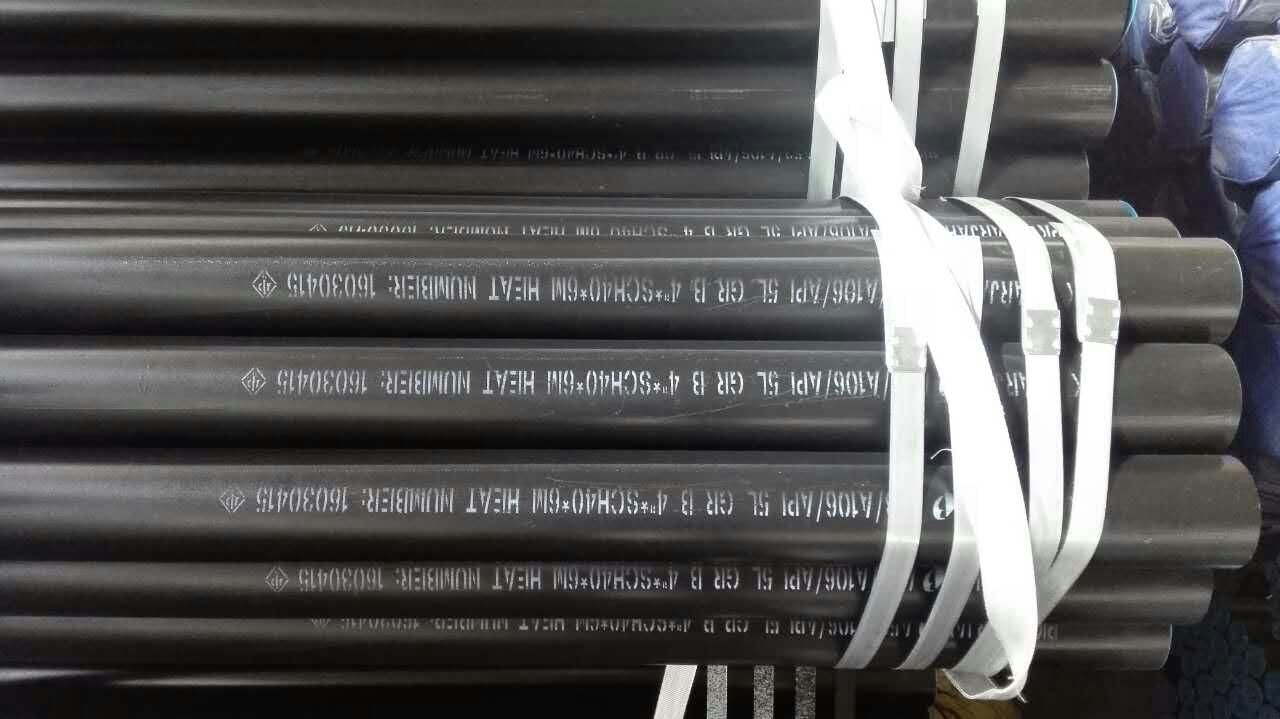

api5lx52 specification

Another essential aspect of the API 5L X52 specification is its classification of the pipe into different categories, namely PSL1 and PSL2. PSL2 offers additional testing requirements and stricter quality control measures compared to PSL1. This distinction allows engineers and project managers to choose the appropriate grade of pipe based on the specific demands of their projects, such as the environment and operational pressure.

As industries worldwide continue to advance towards more sustainable practices, the materials used in pipeline construction are also evolving. API 5L X52 pipe is often coated with various protective layers to enhance its durability and resistance to corrosion, which is particularly vital in environments where the risk of environmental degradation is high.

In conclusion, the API 5L X52 specification plays a pivotal role in establishing standards for pipeline materials critical to the oil and gas sector. Its emphasis on mechanical properties and quality assurance ensures that pipelines constructed from X52 steel can withstand the demanding conditions of transportation, thus safeguarding energy resources and maintaining operational efficiency. As such, adherence to this specification is imperative for the longevity and reliability of pipeline systems globally.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024