-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 11, 2024 00:24 Back to list

API 5L X52M PSL2 Specification Overview and Key Features for Steel Pipe Applications

Understanding API 5L X52M PSL2 Specification

The API 5L X52M PSL2 specification is a crucial part of the oil and gas industry, particularly for the transportation of natural gas and petroleum. This specification, established by the American Petroleum Institute (API), outlines the seamless and welded steel pipes used for pipeline transportation systems. API 5L delivers a framework for the material and design of pipes to ensure safety, reliability, and efficiency, particularly under various environmental conditions.

Key Features of API 5L X52M PSL2

1. Grading System The API 5L specification uses a grading system that categorizes pipes based on their yield strength. The X in X52M denotes the minimum yield strength of 52,000 psi (pounds per square inch). Higher 'X' values indicate greater strength, allowing for the transportation of gas and oil under high pressure and adverse conditions.

2. Material Properties The X52M grade is classified under PSL2 (Product Specification Level 2), which indicates enhanced mechanical properties and chemical composition requirements compared to PSL1. This includes lower maximum levels for sulfur and phosphorus, contributing to improved toughness and resistance to brittle fracture. These properties are vital for pipelines operating in regions that experience severe climatic variations.

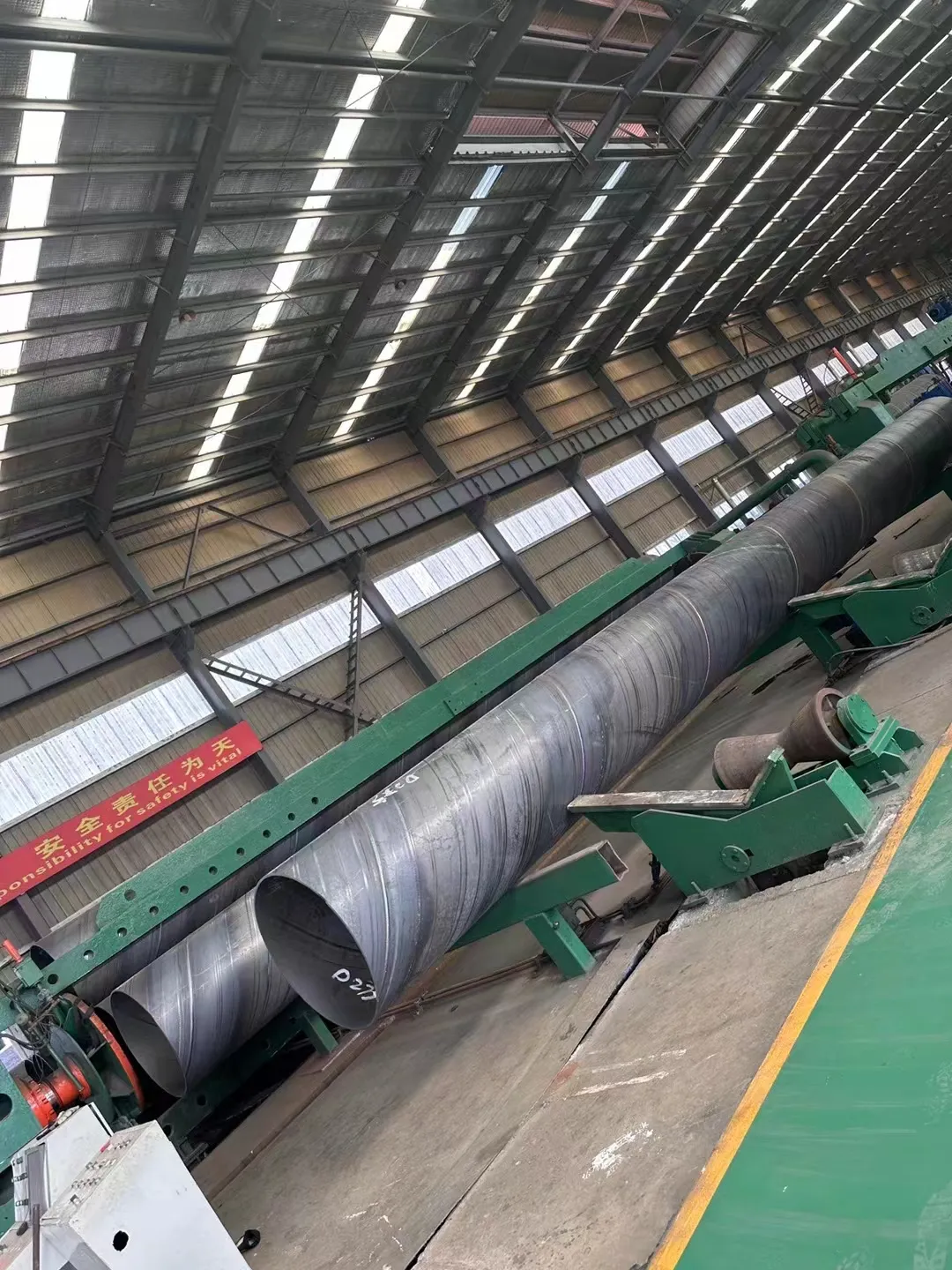

3. Manufacturing Process The manufacturing of X52M PSL2 pipes can involve both seamless and welded methods. The choice between these methods depends on the specific application and the required specifications. Seamless pipes are produced without a seam or weld and are typically used for higher pressure applications, while welded pipes are constructed by welding steel strips together and are often used where lower pressures are involved.

Applications of API 5L X52M PSL2

API 5L X52M PSL2 pipes are predominantly utilized in the oil and gas industries for the transportation of natural gas, crude oil, and other fluids. Their ability to withstand high pressure makes them ideal for long-distance pipelines that connect gas fields with distribution systems or refineries. Furthermore, the enhanced properties of PSL2 pipes make them suitable for challenging environments such as subterranean installations or offshore applications where safety and durability are paramount.

api 5l x52m psl2 specification

Advantages of Using API 5L X52M PSL2

The API 5L X52M PSL2 specification offers numerous advantages for the construction and operation of pipelines

- High Strength With a minimum yield strength of 52,000 psi, these pipes can handle high-pressure demands, ensuring a consistent flow of materials. - Durability The chemical composition and mechanical properties of X52M PSL2 pipes enhance their longevity, reducing the frequency of repairs and replacements.

- Safety The stringent quality control measures that accompany this specification ensure the safety of operations, minimizing the risk of leaks or pipe failures.

- Standardization Being a widely accepted standard, API 5L X52M allows for the integration of various components in pipeline systems, simplifying procurement and logistics.

Conclusion

In conclusion, the API 5L X52M PSL2 specification plays a vital role in the oil and gas industry by providing guidelines for the manufacture and use of high-strength steel pipes. Its attributes—high yield strength, enhanced material properties, and versatile applications—make it an essential benchmark for safe and efficient pipeline transportation. As the industry evolves, complying with such specifications will be crucial to meet the growing demands for energy while maintaining safety and environmental protection. The continued development and adherence to these standards ensure that pipeline infrastructure remains robust, reliable, and ready for the challenges of the future.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024