-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 11, 2024 02:20 Back to list

Exploring the Characteristics and Applications of API 5L X52N Steel Pipe

Understanding API 5L X52N The Key to Pipeline Integrity

In the world of industrial piping and transportation, the significance of reliable materials cannot be overstated. Among the myriad of specifications that guide the manufacturing and use of pipes, API 5L X52N stands out for its robust properties and diverse applications. This article delves into the characteristics, uses, and advantages of API 5L X52N, illuminating its critical role in maintaining the integrity of pipeline systems.

What is API 5L?

API 5L is a specification developed by the American Petroleum Institute (API), which outlines standards for the manufacturing of line pipes utilized in the transportation of oil, gas, and water in the petroleum and natural gas industries. The designation X52 refers to a specific grade within this specification, where the 'X' indicates the minimum yield strength in thousands of pounds per square inch (psi). For X52, this strength is 52,000 psi. The 'N' in X52N denotes that the pipe has undergone normalizing treatment, a process that improves mechanical properties by refining the microstructure of the steel, enhancing its toughness and ductility.

Mechanical Properties

One of the key features of API 5L X52N pipe is its impressive mechanical properties. It typically possesses a yield strength of 52,000 psi and a tensile strength of 70,000 to 84,000 psi. The elevation of these properties through normalization means that the X52N grade can withstand harsh environmental conditions and high-pressure applications, making it suitable for various conditions encountered in the oil and gas industry.

Additionally, API 5L X52N exemplifies excellent weldability, which is crucial for creating robust pipeline joints. The ability to easily join with other grades and materials ensures that engineers can design efficient and safe pipeline systems without concern for material compatibility.

api 5l x52n

Applications of API 5L X52N

API 5L X52N pipes are primarily used in the oil and gas sector for transporting fluids over long distances. This includes transportation of natural gas, crude oil, and various other liquids. Its high strength makes it particularly suitable for projects that demand the pipeline to bear heavy loads while withstanding external pressure and harsh environmental conditions, such as extreme temperatures and high seismic activity.

Beyond the oil and gas industry, X52N pipes find usage in water supply systems and structural applications where higher strength steel is required. The versatility of this material allows it to adapt to multiple industries, enhancing the overall efficiency of energy transfer systems.

Advantages of API 5L X52N

The choice of API 5L X52N offers several key advantages. Firstly, its high tensile strength not only increases the pipeline’s durability but also extends its operational lifespan, reducing maintenance and replacement costs over time. Secondly, the normalization process that enhances its mechanical properties allows for superior performance even under demanding stress conditions. Moreover, the ease of fabrication and welding capabilities means that installation processes can be streamlined, cutting down project timelines and costs.

To conclude, API 5L X52N is a vital specification that underscores the importance of using high-quality materials in pipeline construction and maintenance. Its capacity to withstand environmental stresses and operational demands positions it as a preferred choice in the oil and gas sector, as well as other industrial applications. As the industry continues to evolve, materials like API 5L X52N will remain pivotal in ensuring the integrity and efficiency of modern pipeline systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

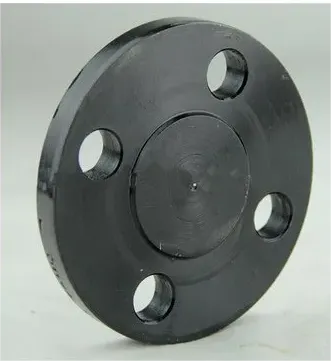

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024