-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 09, 2024 19:12 Back to list

API 5L X52 PSL2 Pipes Overview and Applications in Modern Industries

Understanding API 5L X52 PSL2 Pipes Specifications and Applications

API 5L is a standard specification developed by the American Petroleum Institute (API) that covers seamless and welded steel pipes intended for conveying gas,water, and oil in the pipeline industry. Among the various grades specified under API 5L, the X52 grade is particularly important, especially in its PSL2 (Product Specification Level 2) variant. Understanding API 5L X52 PSL2 pipes involves delving into its specifications, applications, manufacturing processes, and the importance of its properties.

Specifications of API 5L X52 PSL2 Pipes

The API 5L X52 PSL2 pipes are designated for high-strength applications that require durability and resistance to harsh environments. The X in X52 indicates the minimum yield strength of the steel, which is 52,000 psi, making it suitable for high-pressure applications. The PSL2 designation signifies that the pipe meets additional requirements for chemical properties, mechanical properties, and testing compared to PSL1.

The chemical composition of X52 steel typically includes carbon, manganese, phosphorus, sulfur, silicon, and nickel. The presence of these elements contributes to the pipe’s toughness and weldability. The X52 pipes are available in various sizes and wall thicknesses, which makes them versatile for different applications in the oil and gas industry, as well as other sectors.

Manufacturing Process

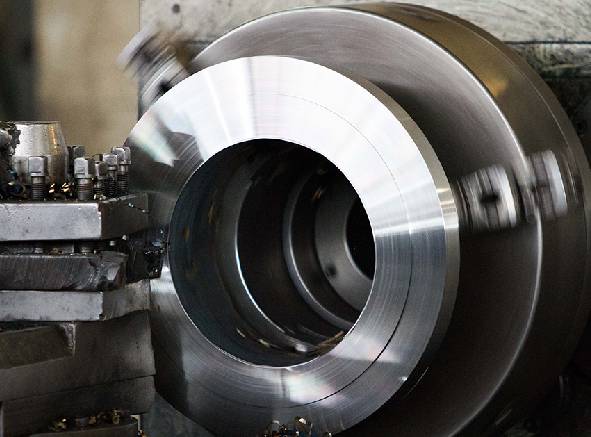

API 5L X52 PSL2 pipes are manufactured using various methods, including both seamless and welded processes. Seamless pipes are made by extruding a solid round billet, which creates a hollow tube without welds. This process is often favored in high-pressure applications since it eliminates the risk of weld-related failures.

api 5l x52 psl2 pipes

Welded pipes, on the other hand, are fabricated by rolling plates to form a cylinder and welding the edges together. Regardless of the manufacturing process, X52 PSL2 pipes undergo rigorous quality control and testing to ensure they meet the standards set forth by API. This includes non-destructive testing, dimensional checks, and pressure testing to confirm that the pipes can withstand anticipated stresses.

Applications of API 5L X52 PSL2 Pipes

API 5L X52 PSL2 pipes are primarily used in the oil and gas industry for transporting oil, natural gas, and other fluids. Their strength and resistance to corrosion make them well-suited for both onshore and offshore applications, where external conditions can be challenging. Additionally, their high yield strength allows for the construction of longer pipeline spans, thus minimizing the number of joints and reducing the risk of leaks.

Apart from oil and gas, these pipes are also utilized in the water transportation industry, as well as in industrial processes that require the movement of fluids under pressure. The versatility of X52 PSL2 pipes also enables their use in structural applications, such as pilings and supports in building projects.

Conclusion

API 5L X52 PSL2 pipes are a critical component in modern pipeline systems, renowned for their strength, durability, and versatility. As industries continue to evolve and face new challenges, the demand for high-quality piping solutions like X52 PSL2 is expected to grow. With their robust properties and wide range of applications, they remain an essential choice for engineers and project managers seeking reliable pipeline solutions in today’s demanding environments. Understanding the specifications and applications of API 5L X52 PSL2 pipes not only highlights their importance in various industries but also emphasizes the ongoing need for innovation and quality in pipe manufacturing.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024