-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 01, 2024 00:02 Back to list

API 5L X65 Pipe Specifications and Applications for Oil and Gas Industry

Understanding API 5L X65 Pipeline Specifications and Applications

API 5L X65 is a crucial grade in the realm of pipeline construction and oil transportation. It is a specification established by the American Petroleum Institute (API) for the manufacture of seamless and welded steel line pipe. The 'X' in X65 denotes the minimum yield strength of 65,000 psi, making it suitable for high-pressure applications in the oil and gas industry.

Mechanical Properties and Specifications

The X65 grade pipe is known for its remarkable mechanical properties, which include high strength, weldability, and corrosion resistance. The chemical composition of API 5L X65 typically consists of carbon, manganese, phosphorus, sulfur, and silicon, among other elements. Carbon content usually ranges from 0.10% to 0.25%, and manganese content can be between 0.60% to 1.40%. This composition provides the pipe with the required strength and ductility, essential for pipeline operations.

In terms of dimensions, API 5L X65 pipes come in various diameters, wall thicknesses, and lengths, catering to different project requirements. The typical outer diameter can range from 0.5 inches to 60 inches, while the thickness can vary from 0.3 inches to several inches based on the application. These specifications make X65 pipes ideal for transporting crude oil, natural gas, and other fluids over long distances.

Applications in Oil and Gas Industry

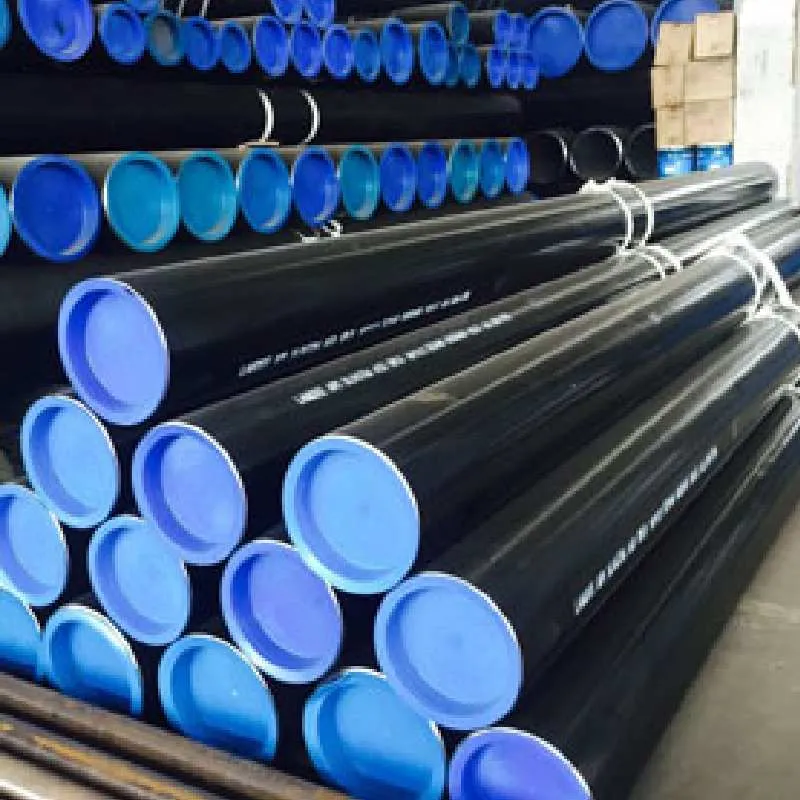

api 5l x65 pipe

The most prominent application of API 5L X65 pipes is in the transportation of oil and gas. Its high yield strength allows for safer and more efficient operation under extreme pressures encountered during transportation. X65 pipes are used in both onshore and offshore pipelines, ensuring the reliable delivery of hydrocarbons from extraction sites to refineries and storage facilities.

In addition to the oil and gas industry, API 5L X65 grade pipes are also utilized in various other sectors. These include water distribution systems, construction, and manufacturing, where robust and reliable piping solutions are necessary. The versatility of X65 tubing makes it an attractive choice for engineers and designers across different fields.

Corrosion Resistance and Coating

An essential aspect of API 5L X65 pipes is their resistance to corrosion, a critical factor in maximizing the lifespan of pipelines. Various coating methods are employed to enhance this property, including fusion-bonded epoxy, polyethylene, and three-layer polyethylene coatings. These coatings protect the pipes from environmental factors, reducing maintenance costs and failures over time.

Conclusion

API 5L X65 pipes represent a standard of excellence in pipeline manufacturing. With their high mechanical strength, versatility in applications, and resistance to corrosion, they are indispensable in various industries, especially oil and gas. As energy demands grow globally, the significance of reliable and durable pipeline solutions such as API 5L X65 will only increase. Understanding these specifications and their applications is essential for engineers, constructors, and stakeholders involved in pipeline projects.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024