-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 21, 2024 18:50 Back to list

api 5l x70 psl2 specification

An Overview of API 5L X70 PSL2 Specification

API 5L X70 PSL2 is a specification established by the American Petroleum Institute (API) pertaining to steel pipes utilized in the transportation of oil and gas. The specification is part of the broader API 5L standards which address the design, manufacturing, and testing of line pipes. Specifically, API 5L X70 PSL2 is considered one of the higher strength grades within this specification, offering enhanced mechanical properties that make it particularly suitable for high-pressure and harsh environmental conditions.

Understanding the Grades and PSL Levels

API 5L provides various grades of steel line pipes; each grade corresponds to specific mechanical properties, chemical compositions, and intended applications. The X in X70 indicates the minimum yield strength in thousands of psi, meaning X70 has a minimum yield strength of 70,000 psi. The PSL (Product Specification Level) is indicative of the quality and additional requirements associated with the pipe, with PSL2 offering a higher standard than PSL1. It incorporates greater testing and quality assurance measures, which are crucial for ensuring safety and integrity in pipeline systems that transport critical materials.

Chemical Composition

The chemical composition of API 5L X70 PSL2 is crucial for its mechanical properties and overall performance. Typically, the steel must contain specific percentages of elements such as carbon, manganese, phosphorus, sulfur, and silicon. For X70, the carbon content is limited to a maximum of 0.12%, which helps achieve a balance between strength and ductility. Manganese is often present in higher amounts to enhance hardenability and toughness.

Mechanical Properties

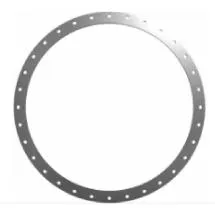

api 5l x70 psl2 specification

The mechanical properties of API 5L X70 PSL2 contribute significantly to its utility in high-stress environments. The minimum yield strength is set at 70,000 psi, while the minimum tensile strength is typically between 80,000 and 90,000 psi. Additionally, the elongation requirements can vary based on the pipe's diameter and wall thickness. This ensures that the pipe can withstand not just the stresses of internal pressure, but also external impacts, making it well-suited for installation in challenging geographic locales.

Applications

API 5L X70 PSL2 is predominantly used in the oil and gas industry, specifically for pipelines that transport crude oil, natural gas, and various by-products. The high yield strength of the X70 grade allows for the construction of thinner walls compared to lower-grade pipes, resulting in a reduction of material costs and weight, without compromising safety or performance. Moreover, its applicability extends to offshore pipelines, water distribution systems, and infrastructure projects that require robust and reliable pipeline solutions.

Manufacturing Process

The manufacturing process of API 5L X70 PSL2 pipes involves several stages, including the selection of raw materials, heat treatment, and welding for seam pipes. The final product must undergo rigorous testing, including non-destructive testing (NDT), to assess mechanical properties, dimensions, and weld integrity. Such comprehensive testing ensures that the pipes can safely operate under the demanding conditions they encounter in service.

Conclusion

In summary, API 5L X70 PSL2 stands as a critical specification in the realm of pipeline construction, particularly in the oil and gas sector. Its high strength, along with stringent manufacturing and testing protocols, ensures safety and reliability in the transportation of energy resources. As industries increasingly push for efficiency and sustainability, the API 5L X70 PSL2 specification will remain an essential foundation for advancing infrastructure that meets modern challenges. Continuous development and adherence to this specification will be integral to the evolution of pipeline systems that are both economically and environmentally viable.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024