-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 30, 2024 06:19 Back to list

ASME A333 Standard for Low-Temperature Service Pipe Specifications and Applications

Understanding ASME A333 A Comprehensive Overview

The ASME A333 standard, titled Specification for Steel Pipe for Low-Temperature Service, plays a pivotal role in the engineering and manufacturing sectors where low-temperature environments are prevalent. Established by the American Society of Mechanical Engineers (ASME), this specification outlines the requirements for seamless and welded steel pipes designed for use at temperatures that can drop as low as -50°F (-45.6°C) and below. This article will provide a comprehensive overview of ASME A333, its significance, material grades, and key applications.

The Importance of ASME A333

In various industries, such as oil and gas, chemical, and power generation, operations often take place in environments characterized by extreme climatic conditions. Low temperatures can significantly impact the mechanical properties of materials, making them brittle and less ductile. This brittleness can lead to catastrophic failures if the materials are not properly specified. ASME A333 addresses these concerns by ensuring that pipes used in such conditions retain their toughness and integrity.

The standard emphasizes not only the mechanical properties of the materials used but also the testing and quality assurance processes, ensuring that any failures due to cold embrittlement are minimized. By adhering to ASME A333, engineers and manufacturers can ensure the reliability and safety of their piping systems in low-temperature operations.

Material Grades

ASME A333 includes several grades of steel pip, with each grade offering different mechanical properties tailored for various applications and temperature conditions. The most commonly referenced grades under this standard include

- Grade 1 This grade is intended for low-temperature applications with a minimum yield strength of 30,000 psi. It provides adequate toughness for many low-temperature environments. - Grade 3 With a higher yield strength requirement, this grade is suitable for applications that may involve more demanding conditions. - Grade 6 This grade offers enhanced toughness, making it suitable for even colder temperatures while maintaining the minimum yield strength. - Grades 7 and 8 These are specialized grades designed for exceptionally low temperatures. They require rigorous testing to ensure their performance in the harshest conditions.

Each grade has specific criteria for chemical composition, mechanical properties, and compliance with industry practices. The proper selection of pipe grade is crucial for ensuring the performance and reliability of a system operating under low-temperature conditions.

asme a333

Testing and Quality Assurance

The ASME A333 standard stipulates rigorous testing methods to evaluate the mechanical properties and integrity of the pipes. This includes tests for impact toughness and tensile strength, both critical in determining how well a pipe will perform in cold environments.

Impact tests are particularly important as they assess the material's ability to absorb energy without fracture. This characteristic is essential in low-temperature environments where materials can become brittle. The tests often adhere to methods outlined in ASTM or similar standards, ensuring that the results are consistent and reliable.

In addition, the standard mandates non-destructive testing (NDT) methods to identify any flaws in the pipe prior to installation. Techniques such as radiography, ultrasonic testing, and magnetic particle testing are commonly employed to ensure the pipes meet the required specifications.

Applications of ASME A333

The applications of ASME A333 pipes are extensive and varied. These pipes are widely used in

- Oil and Gas Industry Due to their ability to withstand low temperatures, A333 pipes are ideal for transporting oil and natural gas in colder regions or during winter months. - Chemical Processing They are used for transporting chemicals that may be sensitive to temperature fluctuations. - Cryogenic Applications In facilities that handle liquefied gases, A333 pipes maintain integrity at extremely low temperatures.

Conclusion

ASME A333 is a crucial standard that ensures the safe and effective use of steel pipes in low-temperature environments. By specifying the requirements for various material grades and emphasizing rigorous testing protocols, it significantly enhances the reliability and safety of piping systems. Industries operating under challenging climatic conditions can leverage this standard to safeguard operations, reduce maintenance costs, and prevent failures. Understanding and adhering to the ASME A333 standard is essential for engineers and manufacturers aiming to maintain the highest safety and performance standards in their piping systems.

Latest news

-

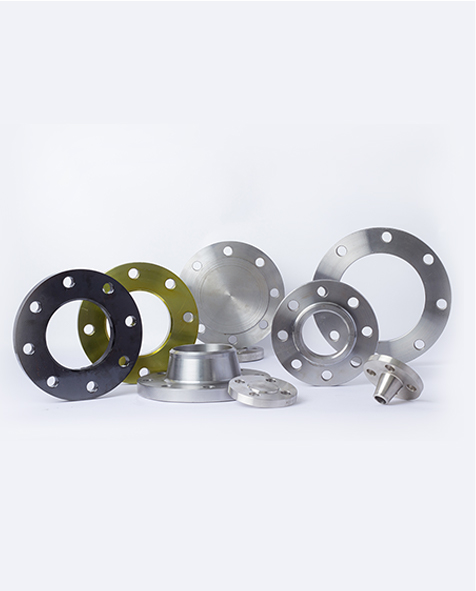

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024