-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 30, 2024 20:39 Back to list

Guidelines for Material Selection and Testing in Mechanical Applications

ASME SB 444 is a critical standard developed by the American Society of Mechanical Engineers (ASME) that focuses on the specifications for the manufacture of wrought stainless steel piping components for high-temperature applications. It serves as a guideline for manufacturers and engineers in the design and production of stainless steel fittings, flanges, and piping systems that are capable of withstanding elevated temperatures while maintaining structural integrity and safety.

.

One of the key aspects of ASME SB 444 is its emphasis on the chemical composition of the stainless steel. The standard outlines acceptable ranges for elements such as chromium, nickel, and molybdenum, which contribute to the alloy's strength and corrosion resistance. It also addresses the impact of impurities and ensures that the material meets specific properties that are crucial for high-temperature service, such as yield strength, tensile strength, and elongation.

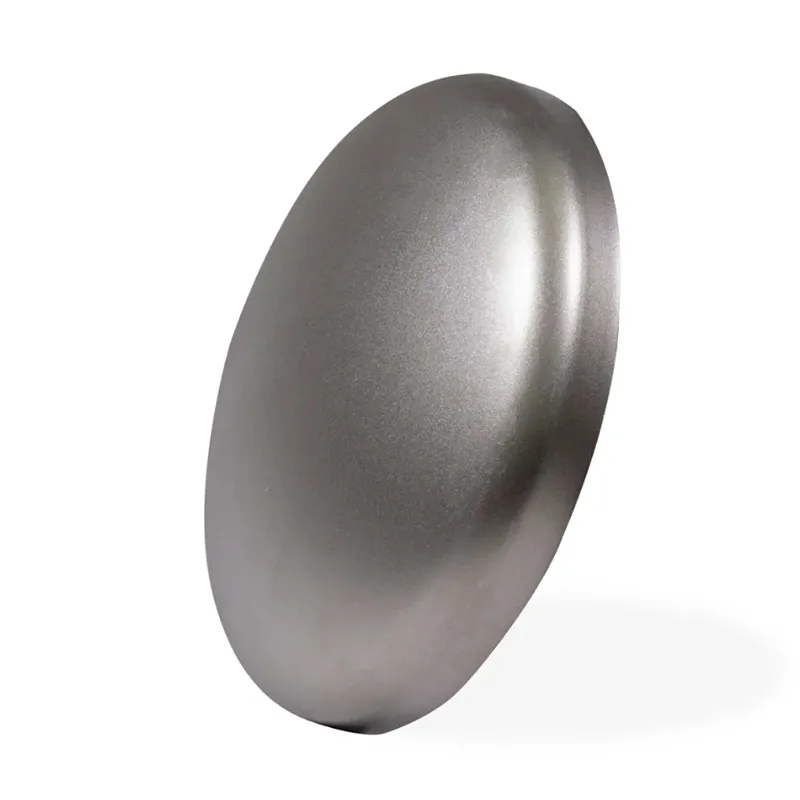

asme sb 444

Additionally, ASME SB 444 provides guidelines for the heat treatment processes that stainless steel components must undergo to achieve desired mechanical properties. Heat treatment can significantly affect the microstructure of the material, thereby influencing its performance under high-temperature conditions. The standard outlines the necessary procedures to ensure that the heat-treated components meet the stringent performance criteria required for critical applications.

Furthermore, the standard incorporates rigorous testing protocols to evaluate the integrity of the components manufactured under its specifications. This includes non-destructive testing methods and the evaluation of finished products to confirm their compliance with the defined mechanical and physical properties. The emphasis on testing is paramount as it ensures that the components will perform reliably throughout their intended service life.

In summary, ASME SB 444 plays a crucial role in establishing a reliable benchmark for the manufacture of wrought stainless steel piping components used in high-temperature applications. By outlining specific requirements regarding chemical composition, heat treatment processes, and testing protocols, this standard enhances safety and performance in industries where failure is not an option. Adhering to ASME SB 444 allows engineers and manufacturers to assure that their materials will withstand the rigors of high-temperature environments, ultimately contributing to more efficient and safe industrial operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024