-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 11, 2024 07:07 Back to list

Properties and Applications of ASTM A333 Grade 6 Low-Temperature Steel Pipe Grades

Understanding ASTM A333 Gr. 6 A Comprehensive Overview

ASTM A333 is a specification developed by the American Society for Testing and Materials (ASTM) that covers seamless and welded steel pipes intended for low-temperature service. Among the different grades specified in this standard, Grade 6 (Gr. 6) is particularly noteworthy due to its distinctive properties and applications. In this article, we will delve into the characteristics, manufacturing processes, applications, and significance of ASTM A333 Gr. 6.

Characteristics of ASTM A333 Gr

. 6ASTM A333 Gr. 6 pipes are made from carbon steel, specifically designed to withstand low temperatures and harsh environments. The primary chemical composition includes

- Carbon (C) Up to 0.30% - Manganese (Mn) 0.60% to 1.20% - Phosphorus (P) Maximum 0.025% - Sulfur (S) Maximum 0.025% These elements contribute to the mechanical properties of the steel, ensuring its performance in extreme conditions. One of the essential features of Gr. 6 is its excellent impact toughness, which is crucial for applications where the material may be exposed to sudden changes in temperature. The steel must provide adequate ductility, preventing fractures in cold environments.

Mechanical Properties

The mechanical properties of ASTM A333 Gr. 6 include

- Yield Strength A minimum of 35,000 psi (240 MPa) - Tensile Strength Ranges from 60,000 to 75,000 psi (414 to 517 MPa) - Elongation Minimum of 30% in 8 inches (200 mm)

These specifications help ensure that pipes made from this grade can withstand rigorous operational conditions while maintaining structural integrity. It is essential to understand that these properties may vary based on the manufacturing process and the specific applications for which the pipes are designed.

Manufacturing Process

astm a333 gr6

The manufacturing of ASTM A333 Gr. 6 pipes involves several key processes, depending on whether the pipes are seamless or welded.

1. Seamless Pipes These are produced through the extrusion or rotary piercing processes, followed by elongation and reduction where the pipe is stretched and shaped into its final diameter. The seamless method ensures that there are no weak points in the structure of the pipe, making it particularly suitable for low-temperature applications.

2. Welded Pipes For welded pipes, steel plates or strips are molded into cylindrical shapes and welded along the seam. Post-welding treatments, such as heat treatment, are often applied to enhance the metallurgical properties and ensure consistency across the length of the pipe.

Applications

ASTM A333 Gr. 6 pipes are widely used in various industries that operate under low-temperature conditions. Some common applications include

- Petrochemical Plants Used for transporting gas and liquids, these pipes maintain their strength and integrity in extreme temperatures. - Cryogenic Applications Gr. 6 pipes are suitable for systems that handle liquefied gases, such as natural gas and LNG facilities. - Pressure Vessels They are often employed in pressure vessels where low-temperature service is crucial for safety and performance.

Significance

The significance of ASTM A333 Gr. 6 lies in its ability to ensure safety and reliability in critical applications. Low-temperature service requirements are stringent, and failure to meet these standards can lead to catastrophic results. By adhering to the specifications outlined in ASTM A333, manufacturers guarantee that their products can withstand the challenges presented by cold environments while maintaining high performance and safety standards.

Conclusion

In summary, ASTM A333 Grade 6 is an essential material in the field of low-temperature construction. Its unique properties, combined with rigorous manufacturing standards, make it a preferred choice for industries requiring dependable and durable piping solutions. Understanding the characteristics, manufacturing processes, and applications of ASTM A333 Gr. 6 is crucial for engineers and decision-makers in ensuring the success and safety of their projects.

Latest news

-

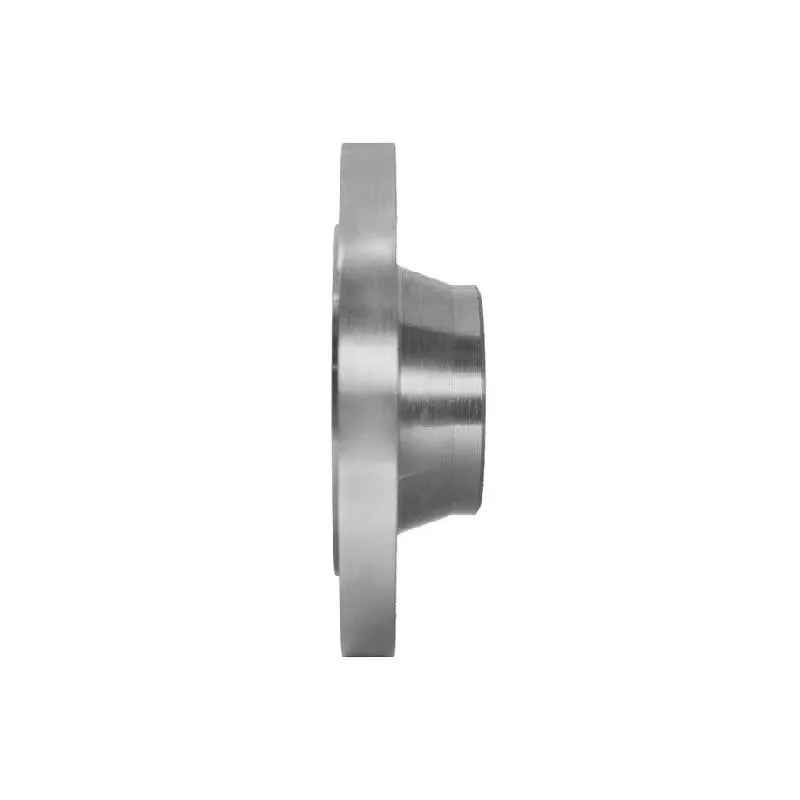

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024