-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 05, 2024 09:04 Back to list

Understanding Backing Rings in ANSI 150 Flange Connections for Enhanced Performance

Understanding Backing Rings in ANSI 150 Applications

In the world of industrial piping and pressure management, the components used in systems are vital for ensuring the safe and efficient transfer of fluids. One such component is the backing ring, particularly within the context of ANSI 150 piping systems. This article explores the concept of backing rings, their significance, and their applications, especially in ANSI 150-rated environments.

What is a Backing Ring?

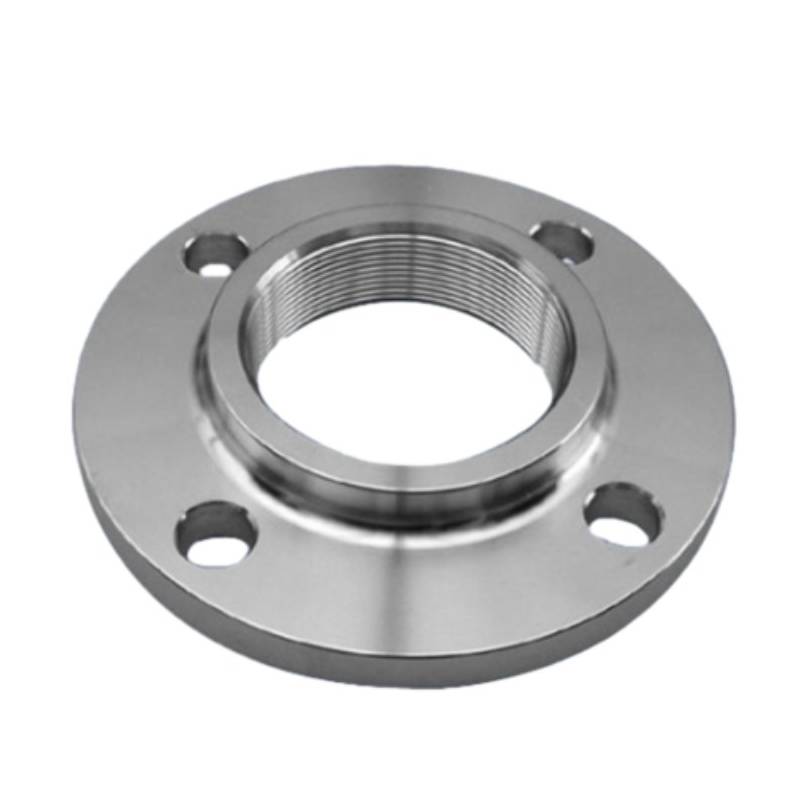

A backing ring is a crucial mechanical component used to support and reinforce the connection between two flanges in a piping system. It is typically a circular piece of material that lies between the flange and the gasket. The primary function of the backing ring is to provide additional strength and stability to the flange joint, helping to prevent the gasket from failing under pressure.

Backing rings are commonly made from various materials, including carbon steel, stainless steel, or specialized composites, depending on the requirements of the application. The choice of material is critical, as it must withstand the operational pressures and temperatures of the system while also resisting corrosion or chemical degradation.

ANSI 150 Standard

The American National Standards Institute (ANSI) establishes various standards to promote safety and efficiency in industrial operations. The ANSI 150 standard specifically refers to flanged connections that can handle a pressure rating of up to 150 pounds per square inch (psi). This standard is vital in various industries, including oil and gas, water treatment, and chemical processing, where safe and reliable fluid handling is imperative.

ANSI 150 flanges have standardized dimensions, allowing for compatibility and interoperability among various components, such as pipes, valves, and fittings. Knowing the ANSI rating of a system is essential for engineers and technicians, as it informs the design and selection of appropriate materials and components, including backing rings.

Importance of Backing Rings in ANSI 150 Applications

1. Enhanced Sealing In ANSI 150 applications, the integrity of the flange seal is paramount. The backing ring helps maintain uniform pressure on the gasket, ensuring a tighter seal and reducing the likelihood of leaks. This is particularly important in systems transporting hazardous materials or fluids under high pressure.

backing ring ansi 150

2. Reduction of Gasket Blowout During operation, dynamic forces can affect the flange connections. A backing ring mitigates these forces by distributing them evenly across the flanged joint, which significantly reduces the risk of gasket blowout. This is crucial in preventing system failures that could lead to catastrophic spills or explosions.

3. Simplified Maintenance Backing rings facilitate easier disassembly and reassembly of flanged connections during maintenance. Their design allows for controlled compression and decompression of gaskets, making it less likely that the gasket will become damaged during maintenance activities.

4. Versatility Backing rings can be used with various gasket types and materials, allowing engineers to tailor the solution to their specific applications and fluid transfer needs. This versatility is beneficial in adapting to different operational stresses and environmental conditions.

Installation and Best Practices

To ensure the effective performance of backing rings in ANSI 150 applications, proper installation is crucial. Here are some best practices

- Ensure Compatibility Always select a backing ring that is compatible with the flange type and gasket being used. The ring should fit snugly between the flange faces without being overly compressed. - Use Proper Torque When tightening the flange bolts, apply the recommended torque in a star pattern. This approach helps maintain even pressure across the flange.

- Inspect Regularly Regular inspections of the flange joints and backing rings should be conducted. Look for signs of wear, corrosion, or deformation, which could indicate a need for replacement.

Conclusion

Backing rings are essential components in ANSI 150 piping systems, providing critical support for flange connections. Their role in enhancing sealing, preventing gasket failures, and simplifying maintenance makes them indispensable in many industrial applications. Understanding their function and adhering to best practices can significantly improve the reliability and safety of fluid transfer operations. As industries continue to evolve, the importance of reliable components like backing rings will only grow, underscoring the need for meticulous attention to detail in piping system design and maintenance.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024