-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 13, 2024 11:55 Back to list

Bending Techniques for Galvanized Steel Pipe Fabrication and Installation

Exploring the Benefits of Bent Galvanized Pipe

In the world of construction and piping, materials play a significant role in determining the durability, safety, and efficiency of infrastructure. Among the many options available, bent galvanized pipes have gained popularity for their unique properties and versatile applications. This article delves into the characteristics, manufacturing process, and applications of bent galvanized pipes, highlighting their advantages in different settings.

What is Bent Galvanized Pipe?

Bent galvanized pipe is essentially steel piping that has undergone a galvanization process to enhance its corrosion resistance. The galvanization usually involves coating the steel with zinc, which serves as a barrier against moisture and environmental elements that can cause rust and deterioration. When the pipe is bent, it is shaped into various configurations to meet specific design needs, making it suitable for a variety of applications in construction, plumbing, and electrical work.

The Manufacturing Process

The production of bent galvanized pipe typically involves two primary stages bending and galvanization. The bending process can be carried out using several methods, including mandrel bending and hydraulic bending, depending on the desired curvature and dimensions. Mandrel bending allows for smooth, gradual curves, whereas hydraulic bending can accommodate more complex shapes.

Once the pipes are bent, they undergo galvanization. The most common method of galvanization is hot-dip galvanization, where the bent pipes are submerged in molten zinc. This process ensures a thick, uniform coating that adheres well to the steel, providing excellent protection against corrosion. After galvanization, the pipes are inspected for quality, ensuring they meet industry standards before reaching the marketplace.

Advantages of Bent Galvanized Pipe

1. Corrosion Resistance One of the most significant advantages of bent galvanized pipes is their resistance to corrosion. The zinc coating minimizes rust formation, ensuring longevity in various environments, especially in humid or outdoor settings.

2. Durability Galvanized pipes are robust and can withstand substantial physical stress. Their strength makes them ideal for construction projects where structural integrity is crucial.

3. Versatility The ability to bend galvanized pipes allows for creative design solutions in piping systems. Whether for plumbing, electrical conduits, or handrails, bent galvanized pipes can conform to a variety of configurations and requirements.

bent galvanized pipe

4. Cost-Effectiveness While the initial cost may be higher than that of non-galvanized options, the longevity and reduced maintenance of bent galvanized pipes make them a cost-effective choice in the long run. Their durability translates to fewer replacements and repairs, ultimately saving time and money.

5. Sustainability The use of galvanized steel in a closed-loop recycling process reduces waste. When no longer needed, galvanized pipes can be recycled, contributing to environmentally sustainable practices.

Applications

The applications of bent galvanized pipes are numerous and diverse. They are commonly used in the following areas

- Construction In buildings, bent galvanized pipes serve as structural components, providing support for various frameworks, including scaffolding and handrails.

- Plumbing Bent galvanized pipes are particularly beneficial in plumbing systems where curved or angled sections are necessary. They can transport water and other fluids effectively while resisting corrosion.

- Electrical In electrical installation, bent galvanized pipes are utilized as conduits to protect wires and cables from environmental damage, ensuring the safety and functionality of electrical systems.

- Agriculture Due to their resistance to rust, bent galvanized pipes often find applications in agricultural settings, such as irrigation systems and fencing.

Conclusion

In conclusion, bent galvanized pipes offer an array of benefits that make them an invaluable choice in various sectors. Their corrosion resistance, durability, versatility, and cost-effectiveness position them as a superior option for construction, plumbing, electrical work, and beyond. As industries continue to prioritize sustainability and efficiency, the role of bent galvanized pipes is likely to expand, solidifying their place as a vital component in modern infrastructure. Whether you are planning a new construction project or seeking reliable piping solutions, bent galvanized pipes are certainly worth considering.

Latest news

-

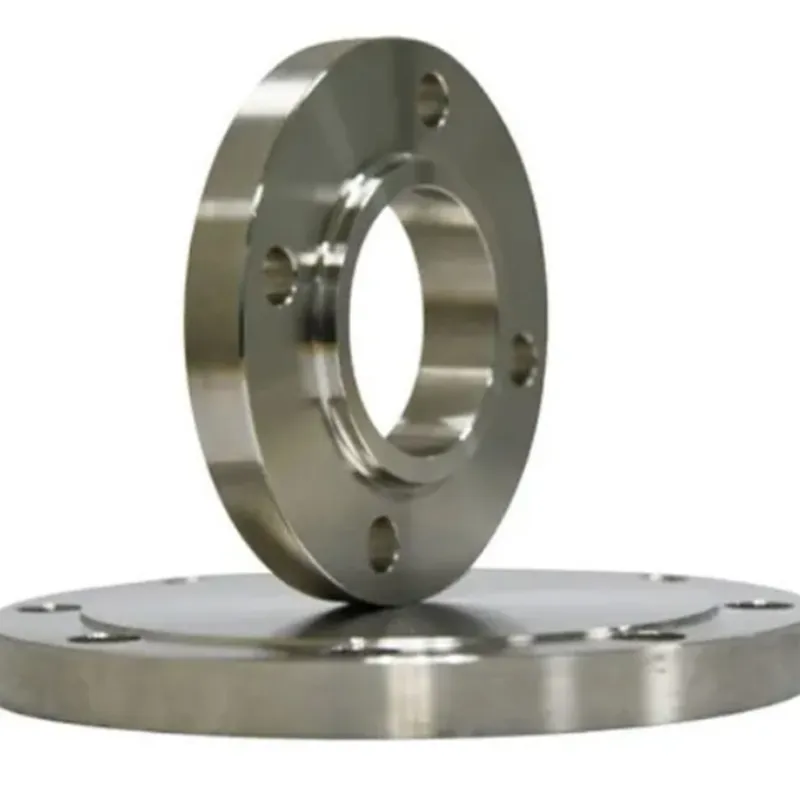

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024