-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 31, 2024 09:21 Back to list

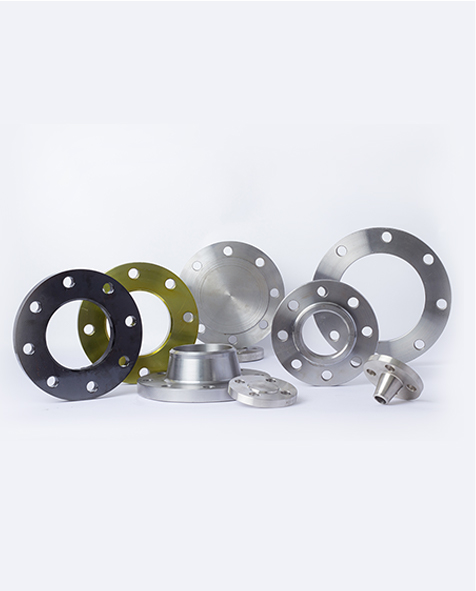

High-Quality Black Pipe Weld Fittings for Reliable Connections

Understanding Black Pipe Weld Fittings A Comprehensive Guide

Black pipe weld fittings play a crucial role in various industries, including plumbing, oil and gas, and construction. These fittings are designed to seamlessly connect black pipes, which are typically made from carbon steel and are used for transporting gas, oil, or water. The unique characteristics of black pipe weld fittings make them an essential component in many applications.

What are Black Pipe Weld Fittings?

Black pipe weld fittings are specialized connectors that allow for the junction of black steel pipes. They are manufactured through a welding process that results in a strong, durable bond, ensuring that fluids and gases are transported safely and efficiently. The term black refers to the dark, uncoated finish of the steel, which is a result of the manufacturing process. Unlike galvanized steel, which is coated to prevent rust, black pipes rely on their strength and integrity to perform effectively in various environments.

Types of Black Pipe Weld Fittings

There are several types of black pipe weld fittings, each designed for specific applications

1. Elbows These fittings allow for a change in direction in the piping system, typically at a 45 or 90-degree angle. Elbows are essential for routing pipes around obstacles or creating efficient pathways.

2. Tees A tee fitting connects three pipes, allowing for a branch line to be formed. This is particularly useful in systems requiring multiple outlets from a single source.

3. Reducers Used to connect pipes of different diameters, reducers enable the transition from a larger pipe to a smaller one, facilitating changes in flow rate or pressure.

black pipe weld fittings

4. Caps and Plugs These fittings are utilized to seal the end of a pipe. Caps cover the end of a pipe completely, while plugs fit into the pipe's opening, providing a tight seal.

Advantages of Black Pipe Weld Fittings

Black pipe weld fittings offer numerous advantages

- Durability Made from robust carbon steel, these fittings endure high pressures and temperatures, making them suitable for various industrial applications.

- Cost-Effectiveness Compared to other materials, black pipe weld fittings are often more affordable while still providing the necessary strength and reliability.

- Ease of Installation Welding black pipe fittings can create a tight, permanent seal that is less prone to leaks compared to threaded fittings. This reduces the chances of costly repairs down the line.

- High Resistance to Heat Black pipes can handle high temperatures, making them an ideal choice for transporting heated materials.

Conclusion

Black pipe weld fittings are indispensable in creating efficient and reliable piping systems across multiple industries. Their strength, affordability, and versatility make them an excellent choice for various applications. Whether you are involved in plumbing, construction, or any sector that requires robust piping solutions, understanding the types and advantages of black pipe weld fittings can significantly impact the safety and efficacy of your projects. Always ensure that you choose the right fittings for your specific needs and follow industry standards for installation and maintenance to maximize their performance.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024