-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 29, 2024 18:51 Back to list

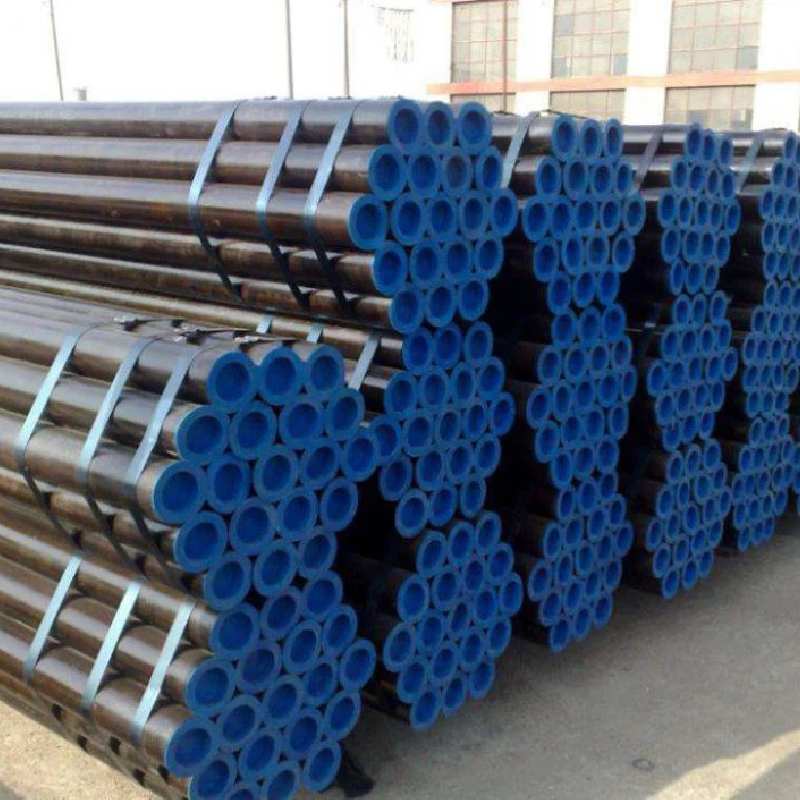

High-Quality Black Steel Pipe Welding Services

Understanding Black Steel Pipe Welding

Black steel pipes are commonly used in construction and plumbing industries due to their strength and durability. They are made from low-carbon steel and have a black finish, which helps to prevent rust and corrosion. Welding black steel pipes is a critical process in various applications, including transferring gas, water, and oil. In this article, we will explore the essentials of black steel pipe welding, including the techniques, challenges, and best practices.

Welding Techniques

When it comes to welding black steel pipes, several techniques can be employed. The most common methods are Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Gas Metal Arc Welding (GMAW). Each technique has its advantages and is chosen based on the specific requirements of the project.

SMAW, also known as stick welding, is popular for its simplicity and portability. It is often used for outdoor projects and in situations where access to power sources is limited. On the other hand, GTAW and GMAW are more suited for precision work and are typically used in controlled environments.

Challenges in Welding

black steel pipe welding

Welding black steel pipes presents unique challenges. One of the primary concerns is the risk of warping due to the heat generated during the welding process. This can compromise the integrity of the pipes and lead to leaks. To minimize warping, welders often employ techniques such as preheating the pipes and controlling the weld pool temperature.

Another challenge is the presence of impurities and contaminants on the surface of the steel. These can affect the quality of the weld. It is essential to clean the pipes before welding by removing any dirt, grease, or oxidation.

Best Practices

To ensure successful black steel pipe welding, following best practices is crucial. Always use the appropriate filler material and welding technique for the specific type of black steel pipe being used. Additionally, proper joint preparation and fit-up are vital for achieving strong and reliable welds.

Finally, regular inspection of the welds and the pipes is necessary to detect any issues early. Non-destructive testing methods, such as ultrasonic testing or radiographic inspection, can help ensure the integrity of the welded joints.

In conclusion, black steel pipe welding is an essential skill in various industries. By understanding the techniques, challenges, and best practices involved, welders can produce high-quality, durable welds that meet industry standards. Whether for residential projects or large-scale industrial applications, proper welding techniques will ensure the safe and efficient transfer of fluids through black steel pipes.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024