-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 28, 2025 03:06 Back to list

schedule 40 welded pipe fittings

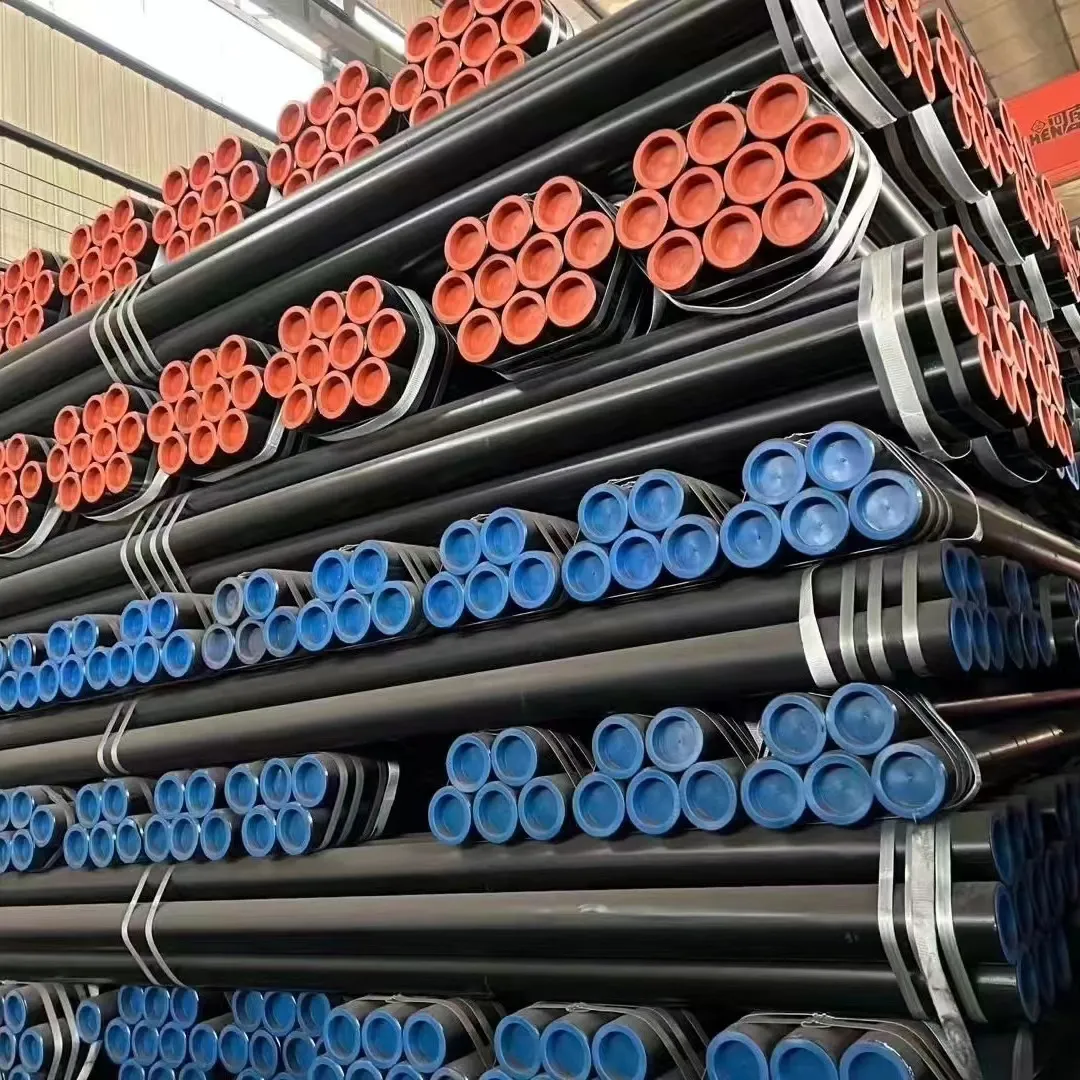

Black welded steel pipes are the backbone of numerous industries, offering unmatched durability, versatility, and cost-effectiveness. Their popularity stems from a blend of experience-backed performance, professional expertise involved in their fabrication, authoritative adherence to industry standards, and trustworthiness in application, making them invaluable to sectors ranging from construction to automotive.

The trustworthiness of black welded steel pipes is further exemplified by a robust track record in practical applications. Whether it’s serving as conduits for transporting water, gas, or oil, or being integral components in building frameworks, these pipes have consistently proven their merit in demanding environments. The ability of black welded steel pipes to resist wear and corrosion, particularly when treated with protective coatings, enhances their longevity and reduces maintenance costs—factors highly valued in large-scale industrial projects. Case studies abound with examples of how industries capitalize on these pipes. In the automotive industry, for instance, they’re used in exhaust systems due to their ability to handle heat and resist atmospheric corrosion. The construction sector utilizes them in scaffolding and structural support because of their load-bearing capabilities. Moreover, in energy sectors, black welded steel pipes serve as vital transitional links in oil and gas pipelines, addressing both rural and urban infrastructure needs. Consumer trust is further solidified through transparent manufacturing processes and extensive testing. Leading manufacturers conduct ultrasounds, x-rays, and hydrostatic testing to verify the integrity of welds and material strength. This rigorous quality control ensures that even under extreme conditions, these pipes perform consistently. For decision-makers involved in procurement, the peace of mind afforded by such testing protocols is invaluable when selecting materials for high-stakes projects. In summary, black welded steel pipes are not just a product of advanced engineering but a synthesis of experience, expertise, and stringent quality standards. Their reliable performance across various industries underscores their indispensable role in modern infrastructure. Choosing black welded steel pipes means opting for a material that combines economic efficiency with structural integrity—a choice evidenced by widespread adoption and trust across sectors. As industries evolve and demand materials that are not only strong but adaptable, black welded steel pipes stand out as a testament to manufacturing excellence and operational reliability.

The trustworthiness of black welded steel pipes is further exemplified by a robust track record in practical applications. Whether it’s serving as conduits for transporting water, gas, or oil, or being integral components in building frameworks, these pipes have consistently proven their merit in demanding environments. The ability of black welded steel pipes to resist wear and corrosion, particularly when treated with protective coatings, enhances their longevity and reduces maintenance costs—factors highly valued in large-scale industrial projects. Case studies abound with examples of how industries capitalize on these pipes. In the automotive industry, for instance, they’re used in exhaust systems due to their ability to handle heat and resist atmospheric corrosion. The construction sector utilizes them in scaffolding and structural support because of their load-bearing capabilities. Moreover, in energy sectors, black welded steel pipes serve as vital transitional links in oil and gas pipelines, addressing both rural and urban infrastructure needs. Consumer trust is further solidified through transparent manufacturing processes and extensive testing. Leading manufacturers conduct ultrasounds, x-rays, and hydrostatic testing to verify the integrity of welds and material strength. This rigorous quality control ensures that even under extreme conditions, these pipes perform consistently. For decision-makers involved in procurement, the peace of mind afforded by such testing protocols is invaluable when selecting materials for high-stakes projects. In summary, black welded steel pipes are not just a product of advanced engineering but a synthesis of experience, expertise, and stringent quality standards. Their reliable performance across various industries underscores their indispensable role in modern infrastructure. Choosing black welded steel pipes means opting for a material that combines economic efficiency with structural integrity—a choice evidenced by widespread adoption and trust across sectors. As industries evolve and demand materials that are not only strong but adaptable, black welded steel pipes stand out as a testament to manufacturing excellence and operational reliability.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024