-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 07, 2024 08:24 Back to list

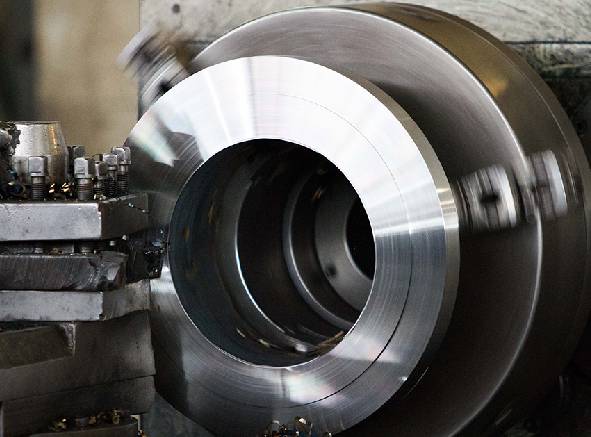

blind flange 6

Understanding Blind Flanges A Key Component in Industrial Applications

In the world of pipeline engineering and fabrication, blind flanges play a vital role. These components are critical in ensuring the integrity and safety of various systems – from water and gas lines to chemical and oil pipelines. This article aims to elucidate the significance of blind flanges, their characteristics, and their applications in industrial settings.

What is a Blind Flange?

A blind flange is a type of flange used to seal the end of a pipe or a vessel. Unlike regular flanges, which are designed to connect two pipe segments or components, a blind flange has no central opening. This design allows it to effectively close off a section of a piping system, preventing fluid or gas from escaping or impurities from entering. Blind flanges are primarily used for maintenance purposes, as they allow for the isolation of specific sections of a pipeline without having to dismantle the entire system.

Material and Standards

Blind flanges come in various sizes and designs and are made from different materials, including stainless steel, carbon steel, and various alloys. The choice of material often depends on the application environment – for instance, stainless steel blind flanges are preferred in corrosive environments due to their resistance to rust and corrosion.

Manufacturers conform to various industry standards when producing blind flanges, such as ASTM, ASME, and ANSI, ensuring they meet specific dimensions and pressure ratings. Understanding these standards is crucial for engineers and project managers in selecting the right blind flange for their application.

Applications of Blind Flanges

blind flange 6

Blind flanges are widely utilized in various industries, including oil and gas, water treatment, chemical processing, and power generation. Some notable applications include

1. Pipeline Systems In pipeline systems, blind flanges are used to seal the ends of pipes, which can be critical during system upgrades or repairs. They allow for safe maintenance and testing, ensuring no leaks occur during the process.

2. Pressure Vessels In pressure vessels, blind flanges are employed as closures to maintain pressure integrity. They provide easy access for cleaning or inspection without compromising the vessel's stability.

3. Hydraulic Systems Blind flanges help in isolating sections of hydraulic systems, allowing for controlled maintenance and repair work without bleeding the entire system.

4. Testing and Inspection During pressure testing and inspection, blind flanges can be installed to facilitate these processes safely. They ensure that no fluid escapes during testing, providing accurate results.

Conclusion

In summary, blind flanges are an essential component of modern engineering and industrial applications. Their ability to seal openings in piping systems and equipment makes them invaluable for maintenance, safety, and operational efficiency. As industries continue to expand and evolve, the importance of reliable components like blind flanges cannot be overstated. Their versatility in various applications, combined with adherence to rigorous industry standards, ensures that they remain a cornerstone of effective pipeline management and engineering practices. Understanding these aspects of blind flanges enables engineers and technicians to make informed decisions, ultimately contributing to the smooth running of industrial processes.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024