-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 09, 2024 23:11 Back to list

Understanding ANSI Blind Flange Specifications and Applications in Industrial Settings

Understanding Blind Flanges ANSI Standards and Their Importance

In the world of piping and construction, the importance of flanges cannot be overstated. Among the various types of flanges, blind flanges play a critical role in ensuring the integrity and efficiency of piping systems. This article delves into the concept of blind flanges, particularly focusing on the American National Standards Institute (ANSI) standards that govern their usage.

What is a Blind Flange?

A blind flange is a solid disk that is used to seal the end of a piping system or to close off a nozzle. Unlike standard flanges, which are designed to connect two sections of pipe, blind flanges do not have a central hole. They are useful in various applications, including pipeline construction, pressure vessels, and any system where a temporary or permanent seal is required. Blind flanges are essential for maintenance activities, allowing for the isolation of sections of a system without having to remove entire piping lengths.

ANSI Standards for Blind Flanges

The ANSI provides a set of standards that establish the specifications for various types of flanges, including blind flanges. These standards outline critical parameters such as size, pressure ratings, materials, and dimensions which are essential for ensuring compatibility and safety across different piping systems.

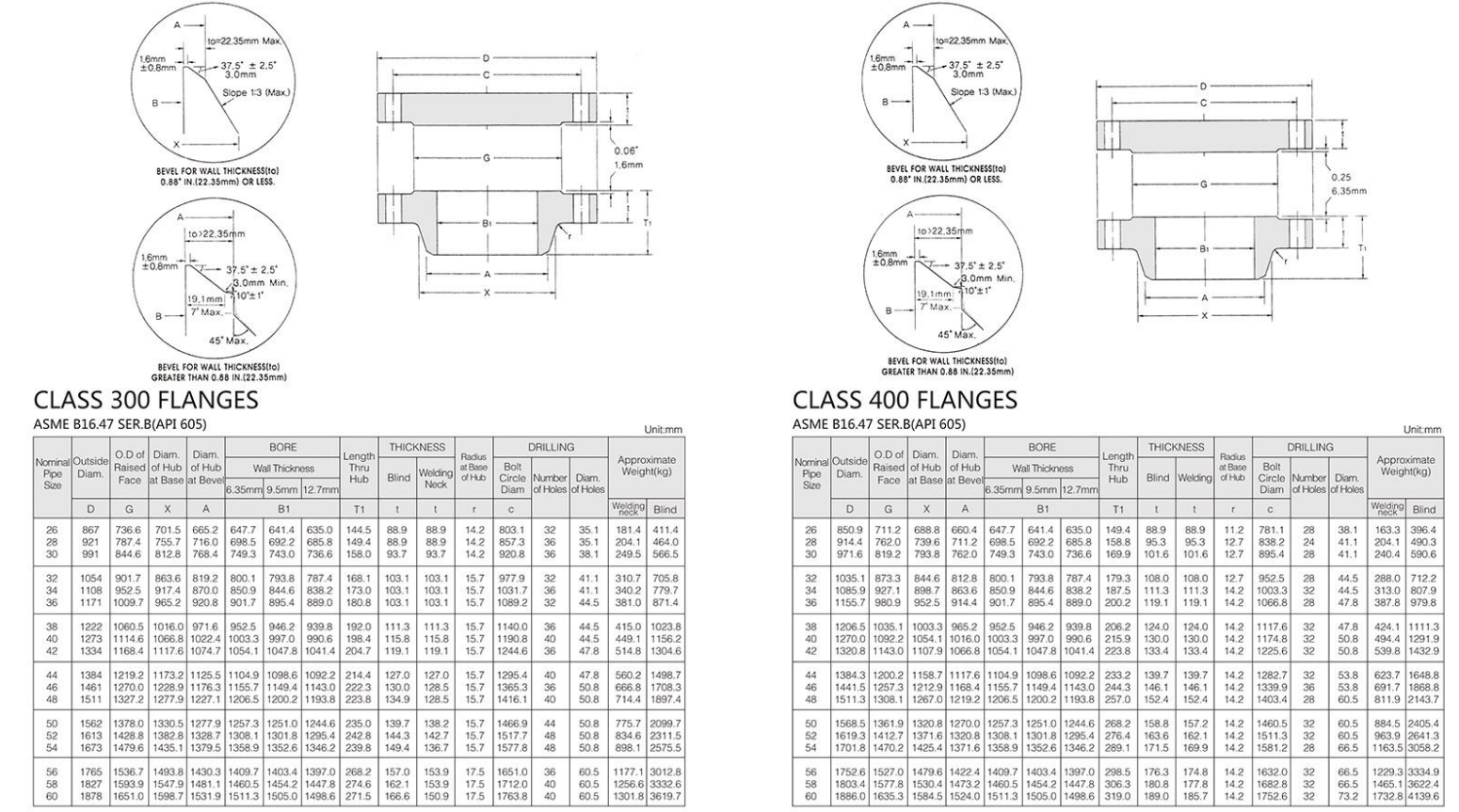

1. Size and Dimensions ANSI standards specify various nominal pipe sizes for blind flanges, typically ranging from 1/2 inch to 72 inches in diameter. The dimensions adhere to the ANSI/ASME B16.5 standard for flanges, detailing the outer diameter, bolt circle diameter, and bolt hole diameter. This uniformity is crucial to ensure that blind flanges fit correctly onto the pipes they are designed to seal.

2. Pressure Ratings Blind flanges come with different pressure ratings, classified as Class 150, Class 300, Class 600, and so forth. These classifications indicate the flange's capability to withstand certain pressure levels, which is vital for applications involving high-pressure systems. The ANSI/ASME B16.5 standard provides comprehensive tables detailing the pressure-temperature ratings for different materials, enabling engineers to select the appropriate blind flange for their specific application.

blind flange ansi

3. Material Specifications ANSI standards also dictate the material compositions for blind flanges, ensuring that they are constructed from adequate materials that can withstand operational conditions. Typical materials include carbon steel, stainless steel, and alloys, each selected based on factors such as temperature, pressure, and the chemical nature of the fluids that will be contained in the pipes.

4. Surface Finish and Bolt Holes The surface finish of blind flanges is another critical aspect covered by ANSI standards. A smooth surface aids in creating a tighter seal, preventing leaks. The standards also specify the arrangement and number of bolt holes, which are essential for proper fastening and security. Generally, the number of bolt holes is proportional to the size of the flange and the pressure rating.

Importance of Using ANSI Standards

Using ANSI standards for blind flanges provides significant benefits in industrial applications. Firstly, adherence to these standards ensures compatibility across different manufacturers, allowing for easier procurement and installation of components in piping systems. This compatibility reduces the potential for leaks and failures, which can lead to costly downtime and safety hazards.

Secondly, ANSI standards promote safety and reliability. By following the established specifications for design, material, and pressure ratings, engineers can ensure that their piping systems will operate effectively under expected conditions. This proactive approach to safety helps to mitigate the risks associated with high-pressure systems and hazardous substances.

Lastly, compliance with ANSI standards often satisfies regulatory requirements, which can be crucial in industries such as oil and gas, chemical processing, and water treatment. Meeting these standards not only helps companies avoid legal repercussions but also enhances their reputation for reliability and safety.

Conclusion

Blind flanges are indispensable components in a variety of piping systems, and understanding ANSI standards is crucial for ensuring their effective and safe use. By adhering to these standards, engineers and manufacturers can create reliable solutions that enhance the safety and efficiency of industrial operations. Whether for temporary isolation, pressure containment, or maintenance purposes, blind flanges remain a vital part of the engineering landscape.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024