-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 28, 2024 19:26 Back to list

Understanding the Functions and Applications of Blind Flange Ends in Piping Systems

Understanding Blind Flanges An Essential Component in Piping Systems

In the realm of piping systems, various components work together to ensure seamless operation, safety, and efficiency. Among these critical components is the blind flange, a vital element that plays a significant role in maintaining the integrity of piping systems across numerous industries, including oil and gas, chemical processing, and water treatment.

What is a Blind Flange?

A blind flange is a type of flange that serves the specific purpose of sealing the end of a piping system. Unlike regular flanges that facilitate connections between two sections of pipe and allow for fluid flow, blind flanges are designed to close off a pipeline. Made from various materials such as stainless steel, carbon steel, and alloyed metals, blind flanges are manufactured to withstand considerable pressure and temperature variations.

Applications and Benefits

Blind flanges are utilized in several applications where it is necessary to isolate a section of the piping system. They are commonly used in maintenance and testing scenarios to enable easy access while preventing leaks. For instance, when a section of a pipeline needs to be repaired or inspected, a blind flange can effectively seal the pipeline, allowing technicians to work safely without the risk of fluid spillage.

One of the key benefits of using blind flanges is their ability to provide a secure barrier against pressure surges and potential leaks. Since they are installed without an opening, blind flanges are particularly effective in preventing the escape of gases, liquids, and other hazardous substances. This makes them an essential component in ensuring safety and environmental compliance in industries that deal with volatile materials.

blind flange end

Design and Specifications

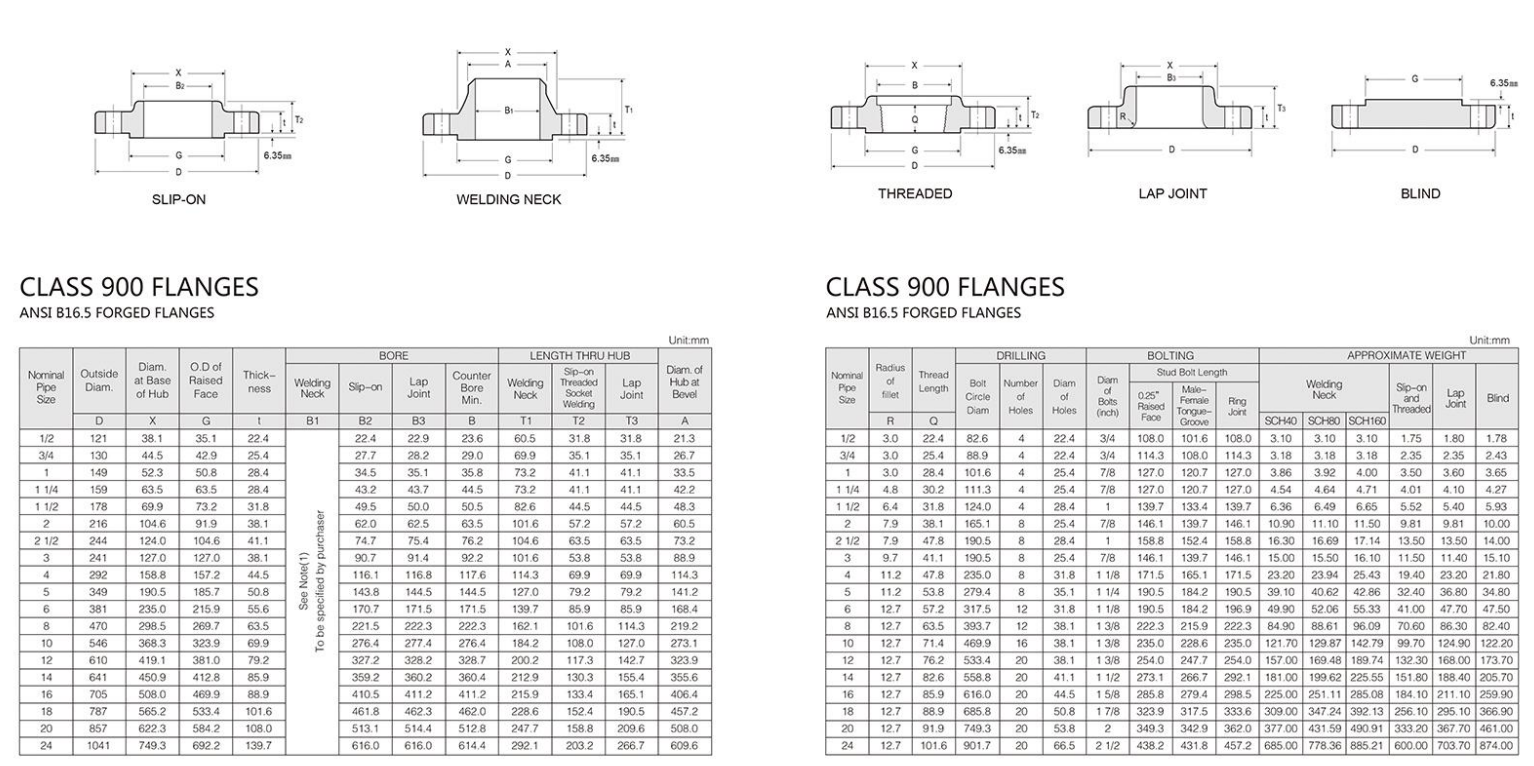

Blind flanges come in various sizes and specifications to accommodate different piping requirements. The dimensions of a blind flange are typically determined by the nominal pipe size (NPS) and the pressure rating, often indicated by the American National Standards Institute (ANSI) or the American Society of Mechanical Engineers (ASME) standards. Common pressure ratings for blind flanges include 150, 300, 600, and 900 psi, categorized according to the intended service conditions.

The design of a blind flange can vary, with options including raised face, flat face, and RTJ (ring-type joint) configurations. The selection of the appropriate design depends on various factors such as the type of fluid being transported, operating temperatures, and the specific requirements of the installation.

Installation and Maintenance

The installation of blind flanges is typically straightforward, requiring standard bolting techniques. It is crucial to ensure that proper gaskets are used to achieve a tight seal, preventing any leakage. Regular inspection and maintenance of blind flanges are recommended to ensure their effectiveness over time, as wear and tear can compromise the integrity of the seal.

Conclusion

In summary, blind flanges are integral components in various piping systems, offering a reliable solution for sealing off pipelines during maintenance, testing, or changes in flow direction. Their ability to withstand pressure while preventing leaks makes them invaluable to industries where safety and efficiency are paramount. Understanding the role and functionality of blind flanges can aid engineers, technicians, and safety personnel in optimizing the design and operation of piping systems, ultimately leading to safer environments and enhanced operational efficiency. As industries continue to evolve, the importance of such components will undoubtedly persist, underscoring the need for innovation and quality in their manufacturing and application.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024