-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 24, 2024 19:52 Back to list

blind plate flange

Understanding Blind Plate Flanges A Complete Guide

In various construction and manufacturing sectors, the importance of flanges in piping systems cannot be overstated. Among the different types of flanges, blind plate flanges hold a prominent place due to their unique functionality in sealing piping systems. This article delves into the key aspects of blind plate flanges, exploring their types, applications, and best practices.

What is a Blind Plate Flange?

A blind plate flange, commonly known as a blind flange, is a type of flange that is used to close the end of a piping system

. Unlike other flanges designed to connect pipe sections, the blind flange has no bore and thus does not allow fluid to flow through it. This feature makes it an essential component for isolating fluid systems, facilitating maintenance, and enabling easy modification of systems.Features of Blind Plate Flanges

Blind flanges are typically designed with a thick plate, making them sturdy and capable of withstanding high pressure. They are available in various materials, including stainless steel, carbon steel, and alloy steel, which makes them suitable for different environmental conditions. The selection of material often depends on the application they are intended for – whether it be chemical processing, water supply systems, or oil and gas industries.

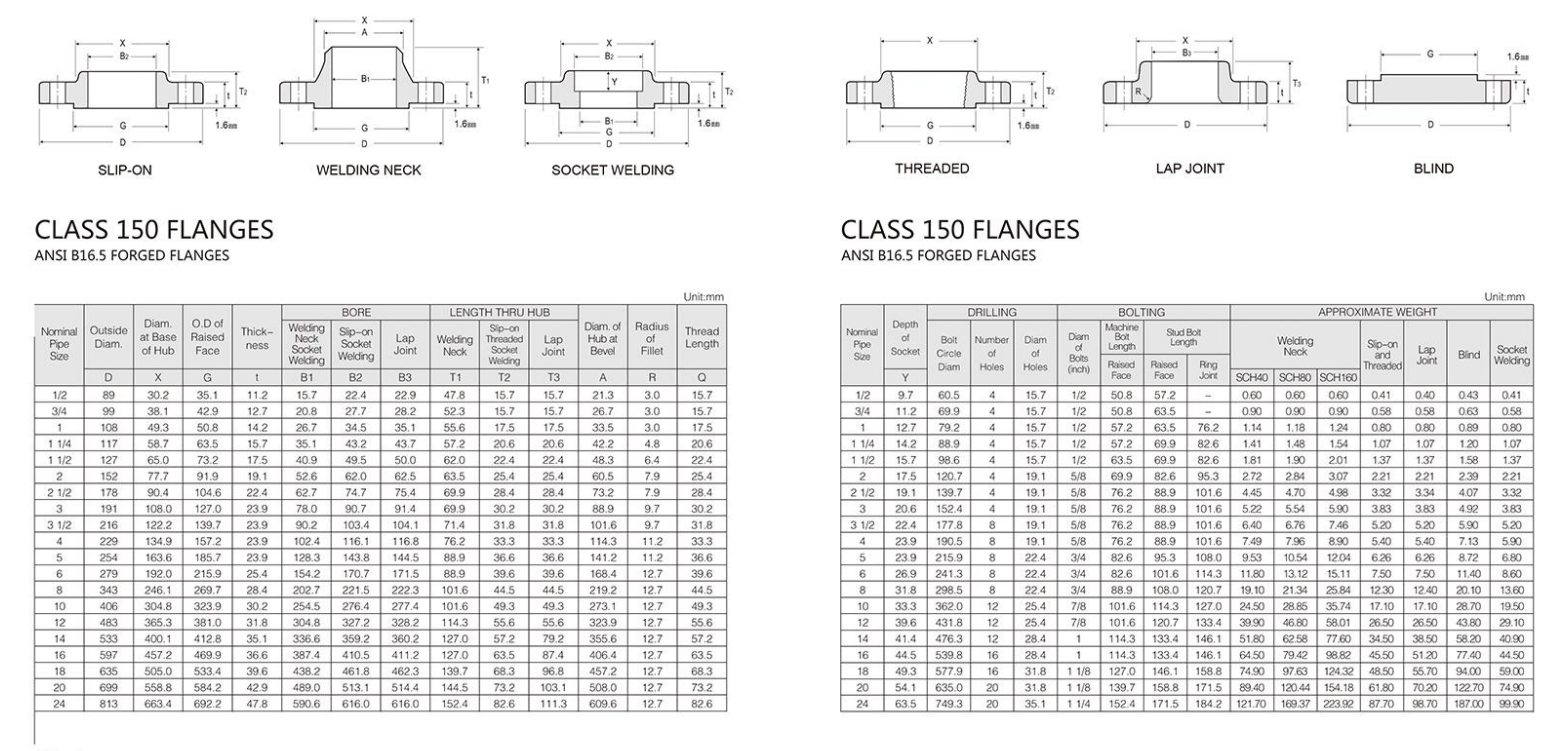

The installation of blind flanges is straightforward. They typically feature a smooth finish on the facing surface that allows for easy sealing with gaskets. Additionally, blind flanges can come in various sizes and pressure ratings, conforming to international standards such as ANSI/ASME, DIN, and JIS.

Applications of Blind Plate Flanges

1. Sealing Off Pipe Ends One of the primary functions of a blind flange is to seal the ends of pipes or vessels. This is crucial for systems that require isolating sections for maintenance or repairs without draining the entire system.

2. Testing and Inspection Blind flanges are often employed during pressure testing of a piping system. By sealing off the ends of the system, engineers can safely test for leaks and ensure the integrity of the installation.

3. Expansion Joints In some scenarios, blind flanges are used in conjunction with expansion joints. They can help in absorbing thermal expansions and contractions of the piping system.

blind plate flange

4. Future Expansion For systems designed with future modifications in mind, blind flanges allow for easy access to blocked sections of piping. If the system needs to be extended or modified, the blind flange can be removed, and additional piping can be installed.

Best Practices for Installation

Successful installation of blind flanges is key to ensuring leak-proof operations. Here are some best practices to consider

1. Proper Alignment Ensuring proper alignment between the blind flange and the connecting pipe is essential. Misalignment can lead to uneven stress distribution and potential failure.

2. Use of Gaskets Always use an appropriate gasket material that can withstand the specific conditions of the application. Correct gasket placement can prevent leakage and ensure a reliable seal.

3. Torque Specifications It is important to adhere to the torque specifications provided by the manufacturer during installation. Over-tightening can lead to flange deformation, while under-tightening can result in leaks.

4. Regular Inspection Periodic checks for signs of wear, corrosion, or leaks are necessary to maintain system integrity. Adequate inspection protocols can detect potential issues before they escalate.

5. Operating Conditions When selecting a blind flange, consider factors like temperature, pressure, and the nature of the fluid. These parameters will dictate the materials and specifications required for safe operation.

Conclusion

Blind plate flanges play a crucial role in various industrial applications where sealing, testing, and future expansion capabilities are needed. Their strength, versatility, and ease of installation make them an indispensable part of piping systems. By following installation best practices and understanding their applications, industries can ensure the safety and efficiency of their fluid handling systems. Whether it's for sealing off a pipe temporarily or preparing for future expansions, blind flanges are a reliable solution in the complex world of pipelines and fluid dynamics.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024