-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 05, 2024 09:24 Back to list

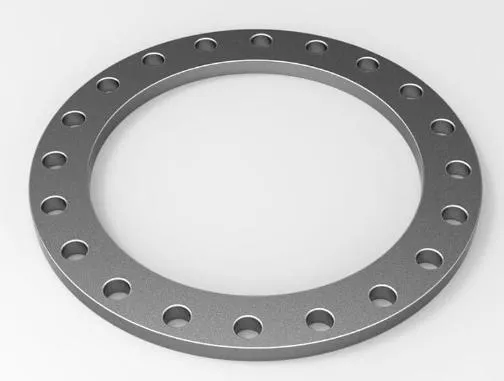

Brief Introduction to DIN 86044 Flange

DIN 86044 flanges are an essential component in various piping systems, providing a secure and leak-proof connection between pipes, valves, pumps, and other equipment. These flanges conform to the German DIN (Deutsches Institut für Normung) standards, which define the specifications and dimensions for various industrial components. DIN 86044 flanges, typically made from durable materials like stainless steel, carbon steel, and alloys, are used across industries including chemical, petrochemical, oil and gas, and water treatment, due to their reliability and strong sealing capabilities.

Key Features of DIN 86044 Flanges

Din 86044 flanges standard are known for their robustness and adaptability. They are designed to ensure a tight and leak-proof joint between two piping components, which is vital in maintaining the efficiency and safety of industrial systems. These flanges typically feature bolt holes around the outer circumference, allowing them to be fastened securely with bolts to another flange or component. The precise manufacturing standards for DIN 86044 flanges ensure high-quality material properties, preventing corrosion and minimizing maintenance needs.

A key feature of these flanges is the raised face design, which creates a pressure-tight seal when paired with a matching gasket. This raised face helps to increase the sealing contact area, making the flange ideal for high-pressure and high-temperature applications.

Materials Used in the Production of DIN 86044 Flanges

The materials used in the construction of DIN 86044 flanges are integral to their performance. Common materials include carbon steel, stainless steel, and alloys such as duplex steel, depending on the requirements of the system in which they are used.

- Carbon Steel:Often used in low to moderate-pressure applications, carbon steel flanges offer strength and durability at a relatively lower cost.

- Stainless Steel:Stainless steel is favored for its resistance to corrosion, making it ideal for harsh environments like chemical processing or marine applications.

- Alloy Steel:In more extreme environments, such as high-pressure or high-temperature conditions, alloy steel flanges provide the necessary strength and heat resistance.

Each material offers specific advantages based on the demands of the installation, with manufacturers choosing the material based on factors like the fluid being transported, the operating pressure, and temperature ranges.

Applications of DIN 86044 Flanges

The versatility of DIN 86044 flanges makes them suitable for a wide range of applications. They are commonly found in industries where robust and leak-tight connections are critical to the functioning of the system. Some of the typical applications include:

- Chemical Processing:In industries that deal with aggressive chemicals, DIN 86044 flanges are used to maintain the integrity of pipelines and equipment, ensuring there are no leaks that could lead to costly damage or safety risks.

- Oil and Gas:These flanges are frequently used in oil and gas systems, where high pressure and temperature are common. The flanges provide a secure connection between pipes, reducing the risk of leaks in critical areas of operation.

- Water Treatment Plants:In water treatment systems, DIN 86044 flanges help in the transportation of water and chemicals through pipelines, ensuring the system operates smoothly and safely.

- Power Generation:In power plants, where steam, water, and gases are transported under high pressure, DIN 86044 flanges are essential to ensure that all connections are stable and leak-resistant.

Advantages of Using DIN 86044 Flanges

The use of DIN 86044 flanges offers several advantages that contribute to their widespread use across industries:

- Durability and Longevity:The flanges are made from high-quality materials that offer excellent durability. This ensures that they last for years even in harsh environments, reducing the need for frequent replacements and minimizing downtime.

- Leak-proof Connections:The tight, secure connections provided by DIN 86044 flanges prevent leaks, which is essential for maintaining the safety and efficiency of industrial processes.

- Ease of Installation and Maintenance:These flanges are designed for easy installation, with bolt holes that allow for quick assembly. Their reliable design also reduces the need for frequent maintenance, saving both time and money.

- Adaptability:With a variety of materials and sizes available, DIN 86044 flanges can be used in diverse applications, ranging from low-pressure water systems to high-temperature industrial processes.

Installation Considerations About DIN 86044 Flanges

Proper installation of DIN 86044 flanges is critical to ensuring optimal performance. The surface of the flanges should be cleaned thoroughly to avoid contamination and damage to the gasket. Care should be taken to ensure that the flange faces are aligned properly, and the bolts should be tightened in a cross-pattern to ensure uniform pressure distribution. Over-tightening can damage the flange, while under-tightening may lead to leaks.

Moreover, the selection of the right gasket material is essential to create a perfect seal. The gasket material should be compatible with the medium being transported, as well as the operating pressure and temperature conditions.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024