-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 15, 2025 02:56 Back to list

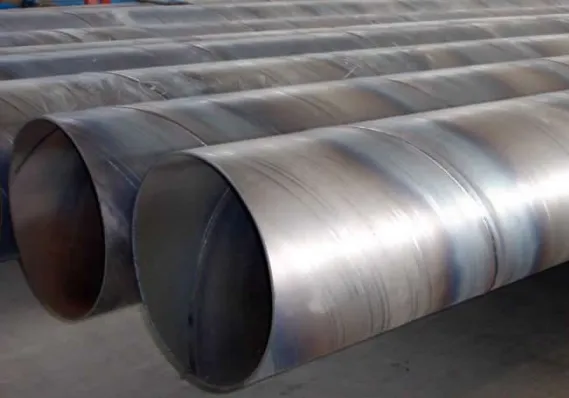

buy galvanized pipe

When considering piping systems for construction, infrastructure, or home projects, galvanized pipes often emerge as a top contender. Crafted through a process that coats steel or iron with a protective layer of zinc, galvanized pipes offer resilience and longevity, meeting diverse demands across various industries. With a history stretching back over 150 years, their continued relevancy speaks to their unmatched utility and durability.

However, making an informed purchase requires understanding the limitations of galvanized pipes. Over time, the internal zinc coating can erode, influencing water quality, a vital consideration if the pipes will carry potable water. Gradual zinc leaching is manageable, but regular water quality testing is advisable to ensure continued compliance with health standards. In regions where the water supply is inherently soft, the likelihood of zinc degradation increases, requiring vigilant maintenance schedules. From an economic standpoint, galvanized pipes present a favorable initial investment, balancing upfront costs with long-term savings derived from durability. Retrofitting existing systems with galvanized alternatives can circumvent the more substantial financial commitments of replacing entire infrastructure frameworks. Businesses and municipalities striving for both economy and efficacy often select these pipes for strategic installations. An often overlooked benefit of galvanized piping is its recyclability. As global industries shift towards sustainable practices, the potential to repurpose materials without sacrificing quality or performance becomes increasingly valuable. The steel core of galvanized pipes, once its functional lifespan concludes, can be recycled, contributing to environmental sustainability while recouping some of the initial material investment. In summary, galvanized pipes remain a studied choice among industry professionals, underscoring an intersection of practical benefits and cost considerations. Their resilience against environmental variables, ease of installation, and economic efficiency form a compelling trio of attributes that enhance both small-scale and extensive infrastructure endeavors. For those responsible for implementing or maintaining plumbing and structural systems, the decision to invest in galvanized piping has reliably positive outcomes. Across this professional landscape, the enduring use of galvanized pipes testifies to their essential role in modern construction and water management systems.

However, making an informed purchase requires understanding the limitations of galvanized pipes. Over time, the internal zinc coating can erode, influencing water quality, a vital consideration if the pipes will carry potable water. Gradual zinc leaching is manageable, but regular water quality testing is advisable to ensure continued compliance with health standards. In regions where the water supply is inherently soft, the likelihood of zinc degradation increases, requiring vigilant maintenance schedules. From an economic standpoint, galvanized pipes present a favorable initial investment, balancing upfront costs with long-term savings derived from durability. Retrofitting existing systems with galvanized alternatives can circumvent the more substantial financial commitments of replacing entire infrastructure frameworks. Businesses and municipalities striving for both economy and efficacy often select these pipes for strategic installations. An often overlooked benefit of galvanized piping is its recyclability. As global industries shift towards sustainable practices, the potential to repurpose materials without sacrificing quality or performance becomes increasingly valuable. The steel core of galvanized pipes, once its functional lifespan concludes, can be recycled, contributing to environmental sustainability while recouping some of the initial material investment. In summary, galvanized pipes remain a studied choice among industry professionals, underscoring an intersection of practical benefits and cost considerations. Their resilience against environmental variables, ease of installation, and economic efficiency form a compelling trio of attributes that enhance both small-scale and extensive infrastructure endeavors. For those responsible for implementing or maintaining plumbing and structural systems, the decision to invest in galvanized piping has reliably positive outcomes. Across this professional landscape, the enduring use of galvanized pipes testifies to their essential role in modern construction and water management systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024