-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 29, 2024 23:04 Back to list

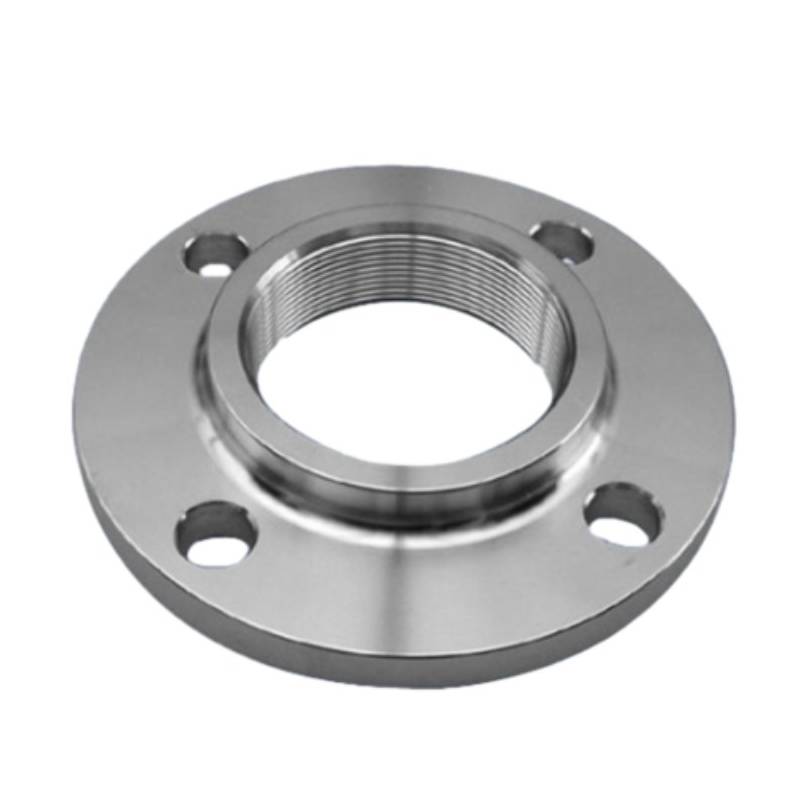

ANSI Flanges Catalog Overview and Specifications for Industrial Applications

Understanding ANSI Flanges A Comprehensive Guide

Flanges are essential components used in piping systems to join two sections of pipe together, allowing for easy maintenance and disassembly. Among the various flange standards, ANSI (American National Standards Institute) flanges are widely recognized and utilized in a multitude of industries, including oil and gas, water treatment, and construction. This article aims to provide a detailed overview of ANSI flanges, their types, standards, and applications.

What are ANSI Flanges?

ANSI flanges comply with the specifications outlined by the ANSI B16 series of standards, which detail the dimensions, tolerances, and ratings for flanges and their connections. These standards ensure interoperability and compatibility among flanges from different manufacturers. ANSI flanges are available in a variety of materials, including carbon steel, stainless steel, and alloy steel, making them suitable for numerous applications.

Types of ANSI Flanges

ANSI flanges come in various types, each designed for specific applications and functional needs. Here are some common types

1. Slip-On Flanges (SO Flanges) These flanges are slipped over the pipe's end and welded both inside and outside. They are easy to install and are commonly used in low-pressure applications.

2. Blind Flanges Used to close the end of a piping system, blind flanges do not have a hole in the center. They are crucial in preventing flow while allowing for inspection and testing of the piping system.

3. Weld Neck Flanges With a long neck that provides a gradual transition for the pipe, weld neck flanges are ideal for high-pressure applications. They are welded to the pipe, creating a strong and seamless connection.

4. Socket Weld Flanges These flanges are designed for small-diameter pipes and are joined through welding. Socket weld flanges provide strong connections and are often utilized in high-pressure systems.

catalogo flanges ansi

5. Lap Joint Flanges These are used in conjunction with a stub end fitting. Lap joint flanges are ideal for systems that require frequent disassembly and maintenance.

Standards and Ratings

ANSI flanges are categorized based on pressure ratings, such as Class 150, Class 300, and Class 600. These classes indicate the maximum pressure the flange can withstand at a specified temperature. In addition to pressure ratings, ANSI flanges are designed to fit various pipe sizes, ensuring versatility in construction and assembly.

The specifications detailed in standards such as ANSI B16.5, which addresses flanges for piping systems, cover everything from flange dimensions to tolerances, ensuring that components fit together correctly. Flanges must also meet specific manufacturing standards regarding material quality and performance to ensure safety and longevity.

Applications of ANSI Flanges

The versatility of ANSI flanges makes them suitable for numerous applications across various industries. They are used in

- Oil and Gas Connecting pipelines and equipment in drilling and processing facilities. - Water Treatment Joining pipes in municipal water systems and wastewater treatment plants. - Pharmaceuticals Ensuring sterile and secure connections in production and storage facilities.

Conclusion

ANSI flanges are vital components in a myriad of piping systems, providing secure connections that support efficient and safe operation. Understanding the different types, standards, and applications of ANSI flanges is essential for engineers and technicians involved in design, maintenance, and construction. By adhering to ANSI standards, industries can ensure compatibility and reliability in their piping systems, facilitating smooth and effective operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024