-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 11, 2024 23:32 Back to list

Choosing the Right Flange Type for Optimal Performance in Pipe Connections and Industrial Applications

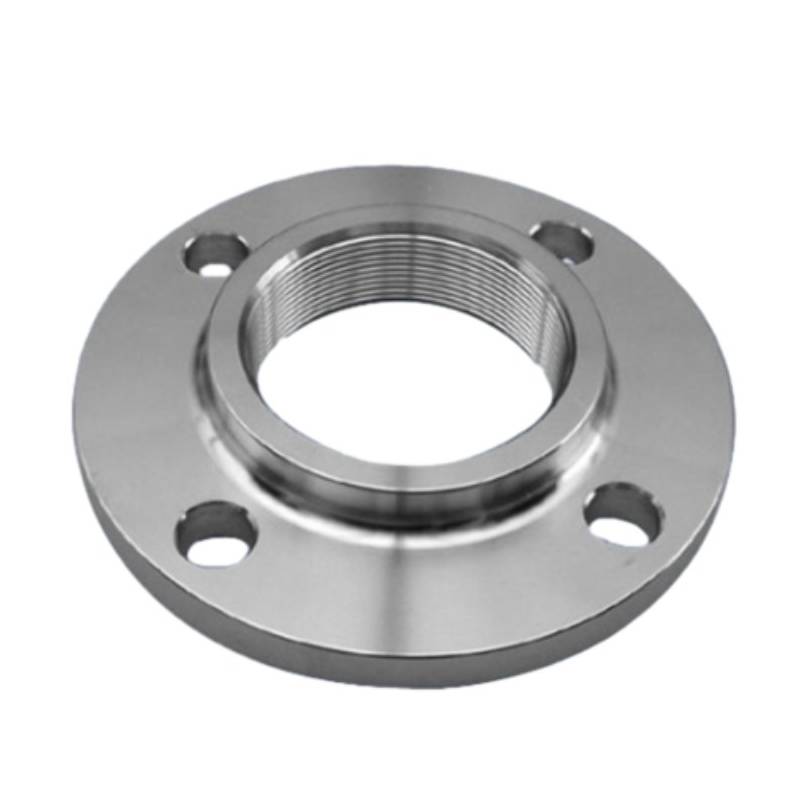

Understanding the 1092% 201% Flange A Key Component in Modern Engineering

Flanges are essential components in various engineering applications, serving as critical junctions in piping systems. Among the myriad types of flanges, the 1092% 201% flange has gained particular attention due to its unique specifications and versatile applications. This article dives into the characteristics, applications, and benefits of the 1092% 201% flange, illustrating why it's a preferred choice in many industries.

Characteristics of the 1092% 201% Flange

The classification of the 1092% 201% flange can initially be perplexing, as it may not correspond directly to traditional flange designations such as ANSI, DIN, or JIS. However, the numerical values typically signify the flange's dimensions, pressure ratings, or specific engineering properties. In essence, a 1092% flange might denote a certain size and shape, while the 201% could refer to its pressure handling capabilities.

Material composition is a crucial aspect of the 1092% 201% flange. Flanges are commonly manufactured from materials like stainless steel, carbon steel, or specialized alloys. The choice of material depends largely on the intended application, with stainless steel flanges being favored for their corrosion resistance, especially in chemical processing and marine applications.

Moreover, the flange may feature various designs such as weld neck, slip-on, or blind flanges, each serving different functions and ease of installation. The weld neck flange, for instance, is ideal for high-pressure systems, while slip-on flanges are typically used in lower-pressure applications due to their simpler installation process.

Applications of the 1092% 201% Flange

The versatility of the 1092% 201% flange allows it to be utilized in a range of industries. In the oil and gas sector, these flanges are often found in pipelines transporting crude oil, natural gas, and other hydrocarbons. The ability of the flange to withstand high pressures and corrosive environments makes it invaluable in this application.

1092 1 flange

Additionally, the chemical industry relies heavily on robust flanges like the 1092% 201% for piping systems that handle hazardous materials. The flange's reliability directly affects the overall safety and efficiency of the entire system. In water treatment and plumbing applications, these flanges provide vital connections, ensuring the seamless flow of water and treatment chemicals.

Moreover, the automotive and aerospace industries also show a growing appreciation for the benefits of the 1092% 201% flange. In these fields, the emphasis is on durability and lightweight materials. The engineering behind the flange's design ensures that it can withstand high temperatures and demanding mechanical stresses.

Benefits of Using the 1092% 201% Flange

One of the primary advantages of the 1092% 201% flange is its flexibility in accommodating various operational demands. Engineers often favor its compatibility with multiple piping configurations, allowing for a more streamlined installation process. This adaptability can lead to significant time and cost savings during both initial installation and future maintenance.

Furthermore, the consistent performance of the 1092% 201% flange under various conditions enhances the reliability of the overall system. Its durability reduces the likelihood of failures, which can lead to costly downtimes and repairs. The flange's ability to handle high pressures allows for the design of more compact systems, which is beneficial in industries where space is at a premium.

Conclusion

In conclusion, the 1092% 201% flange is a cornerstone of modern engineering, characterized by its unique specifications and diverse range of applications. Its material composition, design versatility, and reliability make it an essential component in sectors from oil and gas to chemical processing and beyond. As industries continue to evolve and adapt to new challenges, flanges like the 1092% 201% will undoubtedly play a pivotal role in ensuring efficiency and safety across various applications.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024