-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 23, 2024 12:27 Back to list

Conical Reducer Flange for Efficient Piping System Adaptation and Connection Solutions

Understanding Concentric Reducer Flanges An In-Depth Overview

In the world of piping systems and fluid transport, the components we choose play a critical role in ensuring the efficiency and safety of the operation. Among these components, concentric reducer flanges stand out as essential elements that facilitate the smooth transition of fluids through varying diameters of pipes. This article delves into the significance, applications, design, and benefits of concentric reducer flanges.

What is a Concentric Reducer Flange?

A concentric reducer flange is a type of fitting that connects pipes of different diameters. It allows for a gradual change in the pipe size, which is crucial in preventing turbulence and ensuring the smooth flow of fluids. Unlike eccentric reducers that offset the center of the pipe, concentric reducers maintain a central alignment, making them suitable for applications where maintaining uniform pressure and flow is essential.

Applications of Concentric Reducer Flanges

Concentric reducer flanges are ubiquitous in various industries, including

1. Oil and Gas In the transportation of crude oil, natural gas, and refined products, maintaining a constant flow is crucial. Concentric reducers help in modulating pipe size to meet operational requirements.

2. Water Treatment These flanges are widely used in water treatment facilities where the flow of water may need to be adjusted to fit different pipeline sizes.

3. Chemical Processing In this industry, concentric reducers are vital for transferring chemicals safely and efficiently, ensuring that changes in pipe diameter do not compromise the flow rate or safety.

4. HVAC Systems They are also used in heating, ventilation, and air conditioning (HVAC) systems to optimize airflow and maintain comfort levels.

5. Food and Beverage In food processing, maintaining hygiene and proper flow is paramount, making concentric reducers a preferred choice.

Design and Fabrication

concentric reducer flange

The design of concentric reducer flanges usually adheres to standardized protocols to ensure compatibility across different piping systems. They are available in various materials including stainless steel, carbon steel, and plastic, allowing users to choose according to their specific requirements, such as corrosion resistance, strength, and temperature tolerance.

The fabrication process typically involves techniques like casting, forging, or machining, which results in products that can handle high pressure and temperature conditions. Key specifications often include the pipe diameter, thickness, flange type, and the pressure rating of the reducer.

Benefits of Using Concentric Reducer Flanges

1. Smooth Flow Transition The gradual change in diameter allows for a smooth transition and helps reduce the risk of cavitation, which can lead to pump damage.

2. Pressure Maintenance By maintaining a central alignment, concentric reducers help in retaining pressure better than their eccentric counterparts, making them ideal for systems that operate under high pressure.

3. Versatility Available in various dimensions and materials, they can be tailored to meet the specific needs of different industries.

4. Durability Constructed from robust materials, concentric reducer flanges are built to withstand extreme conditions, ensuring longevity and reduced maintenance costs.

5. Easy Installation The design of concentric reducer flanges typically allows for straightforward installation, making them user-friendly for engineers and technicians.

6. Cost-Effective Solutions While the initial investment in quality flanges may be higher, the long-term benefits of reduced downtime, maintenance, and operational efficiency offer significant cost savings.

Conclusion

Concentric reducer flanges play a crucial role in many industrial applications, facilitating the effective transportation of fluids. Their design contributes to the overall efficiency of systems by ensuring a stable and smooth flow, thus preventing issues related to pressure drops and flow disruption. Understanding the importance of these components can help professionals choose the right fittings for their specific needs, ultimately contributing to the success of their projects.

As industries continue to evolve and adopt advanced technologies for fluid transport, the importance of reliable components like concentric reducer flanges will only grow, reinforcing their place in modern engineering and operational excellence.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

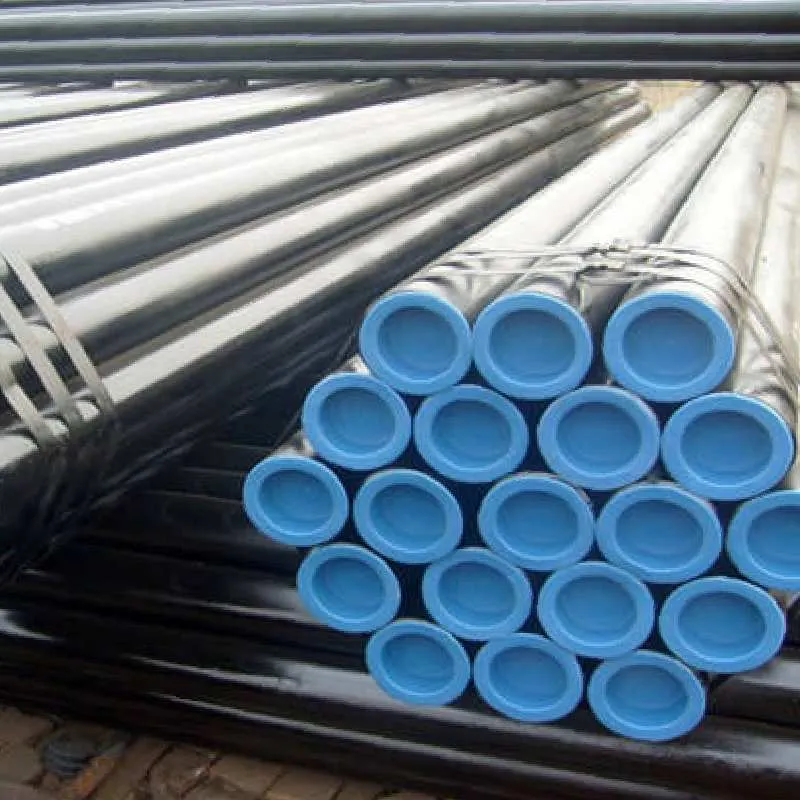

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024