-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 22, 2024 19:18 Back to list

concentric reducer pipe

Understanding Concentric Reducer Pipes A Comprehensive Overview

In the realm of piping systems, the design and functionality of pipes play a critical role in determining the efficiency and effectiveness of fluid transport. Among various types of pipes, the concentric reducer pipe stands out due to its unique design and numerous applications. This article delves into the intricacies of concentric reducer pipes, their advantages, applications, and some considerations for professionals working with these essential components.

What is a Concentric Reducer Pipe?

A concentric reducer pipe is a fitting that connects two pipes of different diameters while allowing fluid to flow smoothly from the larger diameter to the smaller diameter. The term concentric refers to the alignment of the inner and outer diameters so that their centers coincide. This design minimizes turbulence and pressure loss during the transition from one pipe diameter to another, making it an efficient choice for various piping systems.

The reducer can come in different angles, with 30, 45, and 90-degree options being common. The selection of the appropriate angle depends on the specific requirements of the piping system, including fluid type, flow rate, and pressure conditions.

Advantages of Concentric Reducer Pipes

1. Reduced Turbulence One of the primary advantages of concentric reducer pipes is that they significantly reduce turbulence during fluid transitions. Unlike eccentric reducers, which may cause uneven flow and increased friction, concentric reducers maintain a smooth, streamlined flow path.

2. Minimized Pressure Loss The smoother transition of fluids through a concentric reducer results in lower pressure drops compared to other designs. This can lead to enhanced efficiency in pumping systems and reduced operational costs.

3. Versatility Concentric reducers are versatile and can be used in various applications, from industrial setups to residential plumbing. They are often found in petrochemical industries, water treatment facilities, and HVAC systems.

4. Ease of Installation Their symmetrical design makes concentric reducers easier to install compared to eccentric reducers. This can save both time and labor costs during the installation process.

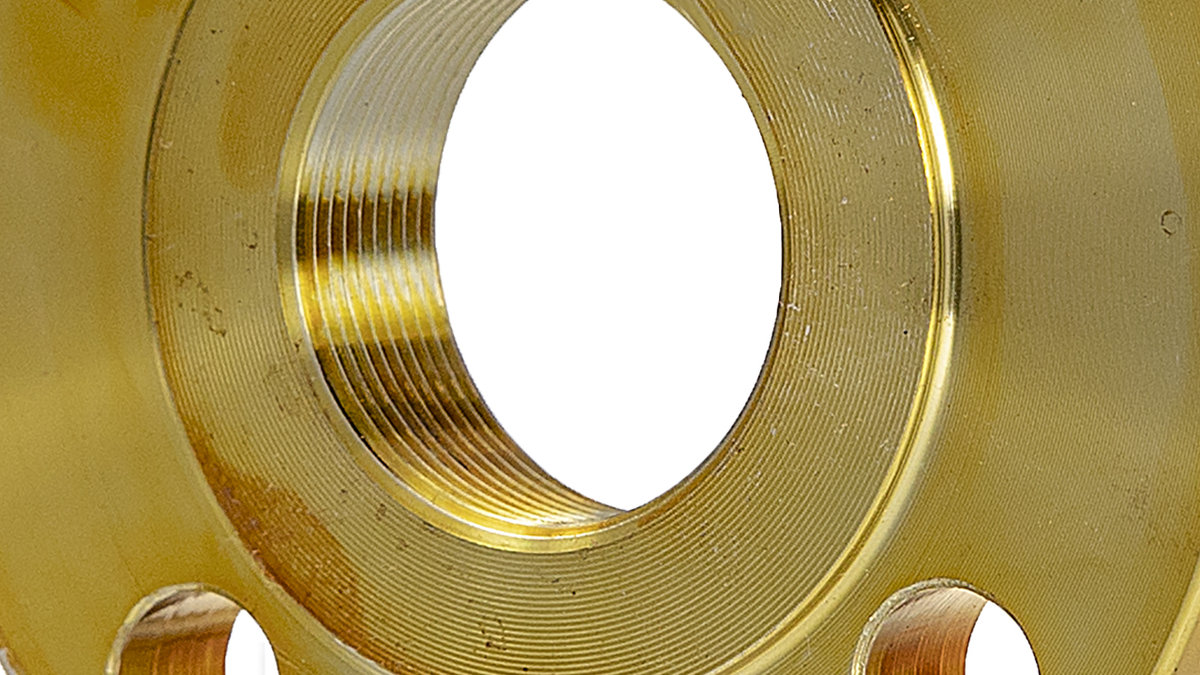

concentric reducer pipe

Applications of Concentric Reducer Pipes

Concentric reducer pipes are used in a wide range of applications across different industries. Some of the most common uses include

1. Water and Wastewater Treatment In water treatment plants, concentric reducers help maintain a steady flow of water and reduce pressure loss in systems that transport water to treatment facilities.

2. Oil and Gas Industry In the oil and gas sector, these reducers are utilized to control the flow of crude oil and natural gas through pipelines, ensuring that pressure levels remain optimal.

3. HVAC Systems In heating, ventilation, and air conditioning systems, concentric reducers are used to connect ductwork, allowing for efficient airflow while minimizing potential pressure drops.

4. Manufacturing Processes Many manufacturing applications require precise fluid flow management, where concentric reducers serve to connect machinery with differing pipe sizes effectively.

Considerations for Use

While concentric reducer pipes offer numerous advantages, there are important considerations for users and engineers. Proper selection of material is vital; materials must be compatible with the fluids being transported and the environmental conditions they will face. Additionally, the correct sizing of reducers is essential—calculating the dimensions based on the flow rates and pressure requirements ensures optimal performance.

Finally, regular maintenance checks are essential. Over time, deposits can build up within pipes, potentially leading to increased pressure drops or blockages. Regular inspection and cleaning can help maintain the efficiency of piping systems that include concentric reducers.

Conclusion

Concentric reducer pipes are an essential component in many fluid transportation systems, offering benefits such as reduced turbulence, minimized pressure loss, and versatile applications. Their straightforward design allows for easier installation and maintenance, making them a preferred choice among engineers and contractors. By understanding their functions and advantages, professionals can leverage concentric reducers to enhance the performance of their piping systems, ensuring effective and efficient fluid flow in various applications.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024