-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 12, 2024 19:35 Back to list

Custom Steel Pipe Bending Services for Unique Applications and Precise Specifications

Custom Steel Tube Bending Crafting Precision and Durability

In today's fast-paced industrial landscape, the demand for custom solutions is at an all-time high. Among these solutions, custom steel tube bending has emerged as a crucial service that caters to various industries. From construction to automotive manufacturing, the ability to bend steel tubes with precision not only enhances the quality of products but also increases design possibilities.

Understanding the Basics of Steel Tube Bending

Steel tube bending is a manufacturing process that involves the bending of steel tubes into specific shapes and angles. Unlike traditional metalworking techniques, which may involve cutting and welding, tube bending allows for a seamless and continuous structure. This aspect is particularly important in applications where strength and integrity are paramount.

There are several methods for bending steel tubes, including

1. Mandrel Bending This technique involves the use of a mandrel, which is inserted into the tube to maintain its shape during the bending process. Mandrel bending is ideal for creating tight bends without causing distortion or wall wrinkling.

2. Rotary Draw Bending In this method, a tube is rotated and drawn around a bending die. This allows for precise control over the radius and angle of the bend, making it a popular choice for custom projects.

3. Compression Bending Utilizing a simple form of pressure, compression bending forces the tube into the desired shape without any excessive deformation. This technique is primarily used for larger diameter tubes.

The Importance of Customization

One of the significant advantages of custom steel tube bending is the ability to create unique shapes tailored to specific requirements. Custom solutions are particularly essential in industries where standard products simply do not suffice. For example

- Architecture In architectural design, custom bent steel tubes are frequently used in structures, railings, and decorative elements

. The ability to bend steel into complex shapes can significantly enhance the aesthetic appeal while maintaining structural integrity.- Automotive Industry Custom bent tubes are employed in exhaust systems, frameworks, and chassis components. The precision of bends influences not only the performance of these parts but also the overall safety and efficiency of the vehicle.

custom steel tube bending

- Furniture Design Innovative furniture designers leverage custom steel tube bending to create sleek and modern designs. The flexibility of tube shapes allows for unique furniture pieces that are both functional and visually appealing.

The Process of Custom Steel Tube Bending

The journey from an idea to a finalized product begins with meticulous planning. Clients typically provide specifications, including dimensions, material type, and desired bends. Skilled engineers and designers then utilize CAD (Computer-Aided Design) software to create detailed models and simulations, ensuring that all aspects meet the required standards.

Once the design is approved, the bending process commences. Advanced machinery and tools are employed to achieve high precision and consistency. Throughout the bending process, quality control measures are implemented to guarantee that the final product aligns with the initial specifications.

Benefits of Using Custom Steel Tube Bending Services

1. Precision Custom steel tube bending services ensure that each bend is executed with exact measurements, resulting in parts that fit perfectly within their intended applications.

2. Cost-Effectiveness By opting for custom bending, businesses can reduce material waste and labor costs associated with additional fabrication processes, such as cutting and welding.

3. Strength Steel is renowned for its strength, and when bent correctly, it retains its integrity. This is crucial for applications requiring high durability.

4. Versatility The ability to create diverse shapes and forms means that custom steel tube bending is applicable across various sectors, from automotive to aerospace.

Conclusion

Custom steel tube bending represents an exceptional fusion of artistry and engineering. As industries continue to evolve, the importance of expertly bent steel tubes becomes increasingly apparent. By offering tailored solutions that meet precise specifications, businesses can maintain a competitive edge while pushing the boundaries of design and functionality. Whether improving a structural design or innovating a new product, custom steel tube bending is undoubtedly paving the way for the future of manufacturing.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

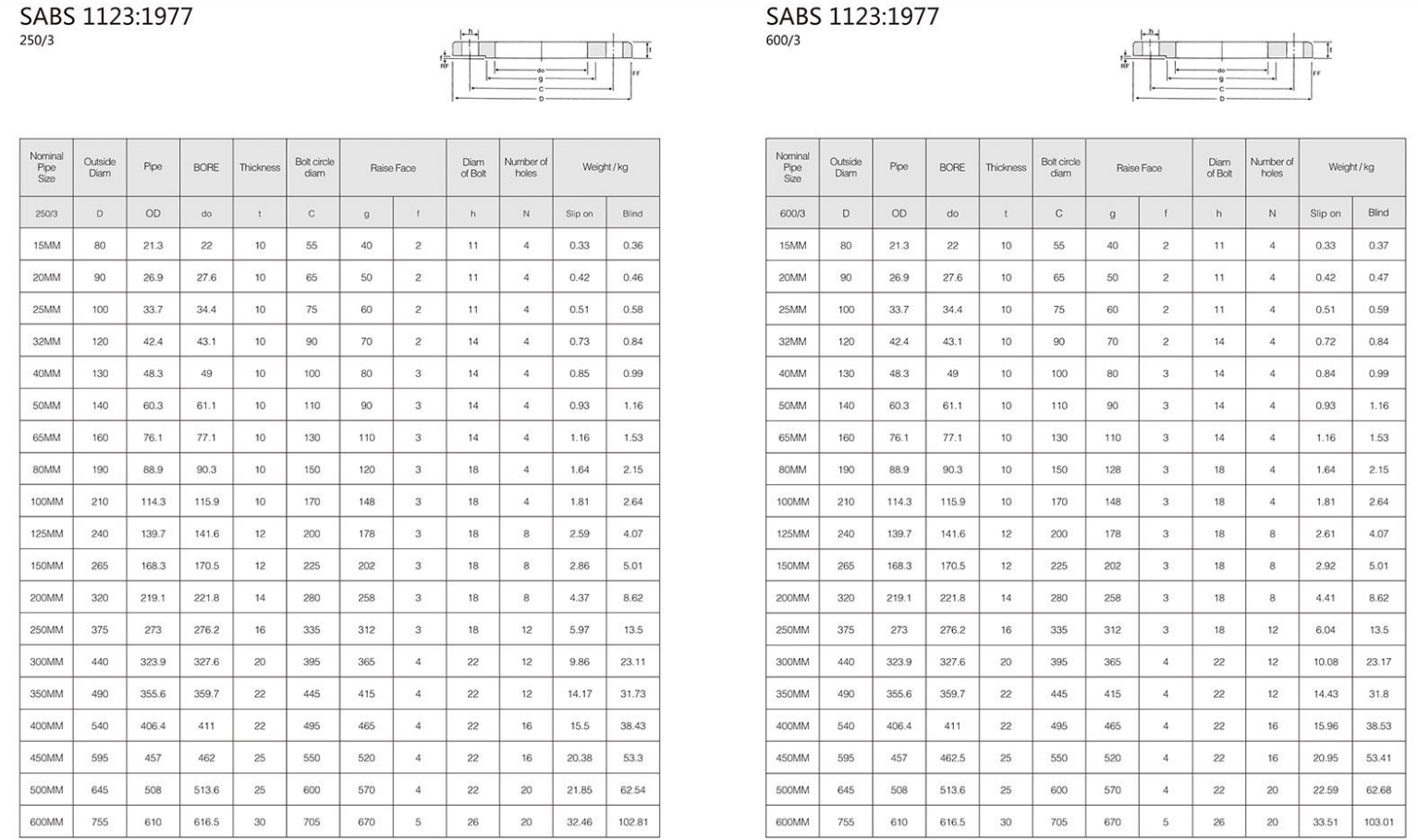

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024