-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 23, 2024 05:56 Back to list

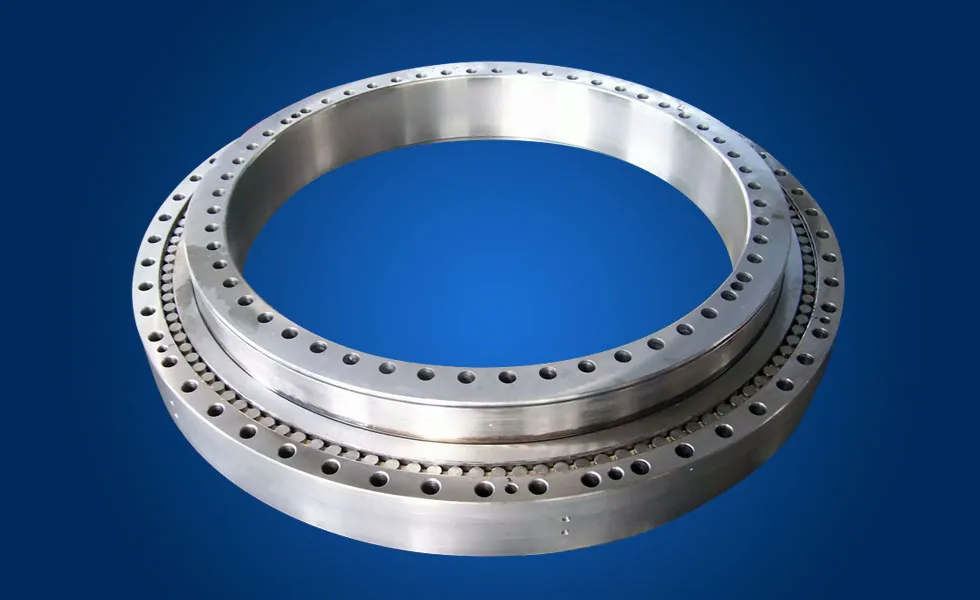

din 200 flange

Understanding DIN 200 Flanges A Comprehensive Overview

Flanges are critical components in piping systems, providing a means to connect pipes, valves, and equipment in various industrial applications. Among the numerous flange standards, the DIN 200 flange specification is widely recognized, particularly in Europe. This standard outlines the dimensions, tolerances, and materials that ensure reliable and leak-proof connections in piping systems.

Understanding DIN 200 Flanges A Comprehensive Overview

One of the key attributes of DIN 200 flanges is their dimensional uniformity. The standard provides specific measurements for flange sizes, bolt holes, and face types, which contributes to the ease of installation and system integrity. Flanges are available in several face types, including raised face, flat face, and ring-type joint, each designed for particular sealing requirements.

din 200 flange

The standardization of DIN 200 flanges facilitates compatibility between different manufacturers, making it easier for engineers and project managers to source components without the need for custom fittings. This not only reduces lead times but also minimizes costs associated with mismatched parts, streamlining the procurement process.

Installation of DIN 200 flanges requires adherence to strict procedures to ensure leakage prevention. Proper alignment, bolt torquing, and the use of suitable gaskets are essential to form a secure seal. Engineers must also consider the pipe stress, temperature fluctuations, and external loads that can affect the integrity of the flange connection over time.

In addition to their versatility and reliability, DIN 200 flanges are also integral to the maintenance and repair of piping systems. Their design allows for easy disassembly and reassembly, enabling efficient inspections and replacements without extensive downtime.

In conclusion, DIN 200 flanges serve a pivotal role in the functionality and efficiency of piping systems across various industries. With their standardized dimensions and material options, they represent an essential element for ensuring safe and effective fluid and gas transport. Understanding the specifications and proper installation techniques of DIN 200 flanges is crucial for engineers and maintenance professionals dedicated to upholding the integrity of industrial operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024