-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 27, 2024 07:40 Back to list

Exploring the Features and Applications of DIN Flange PN10 Standards

Understanding DIN Flanges PN10 A Comprehensive Overview

Flanges are fundamental components in various piping systems, playing a critical role in connecting pipes, valves, pumps, and other equipment. Among the plethora of flange standards used globally, the DIN (Deutsches Institut für Normung) standards are among the most recognized and utilized. This article delves into the specifics of DIN flanges, particularly the PN10 class, discussing their dimensions, applications, and significance in modern engineering.

What is a DIN Flange?

DIN flanges are standardized flanges defined by the German Institute for Standardization, ensuring consistency and reliability in engineering applications. They are designed to facilitate the joining of piping systems while enabling easy dismantling for maintenance and inspection. The PN rating, denoting Pressure Nominal, indicates the maximum allowable pressure that flanges can withstand at a given temperature. In the case of PN10, the maximum pressure capability is 10 bar (approximately 145 psi) at a reference temperature of 20°C (68°F).

Characteristics of DIN PN10 Flanges

DIN flanges are identified by their nominal diameter (DN) and their pressure rating (PN). DIN PN10 flanges typically come in sizes ranging from DN10 (10 mm) to DN600 (600 mm), catering to a wide array of applications across various industries.

Material and Design

DIN PN10 flanges are available in various materials, including carbon steel, stainless steel, and ductile iron, allowing for use in different environments and applications. The choice of material impacts the flange's resistance to corrosion, pressure, and temperature fluctuations. The design of these flanges adheres to exacting geometrical and dimensional standards, ensuring a proper fit and integrity in the piping system.

Dimensions and Specification

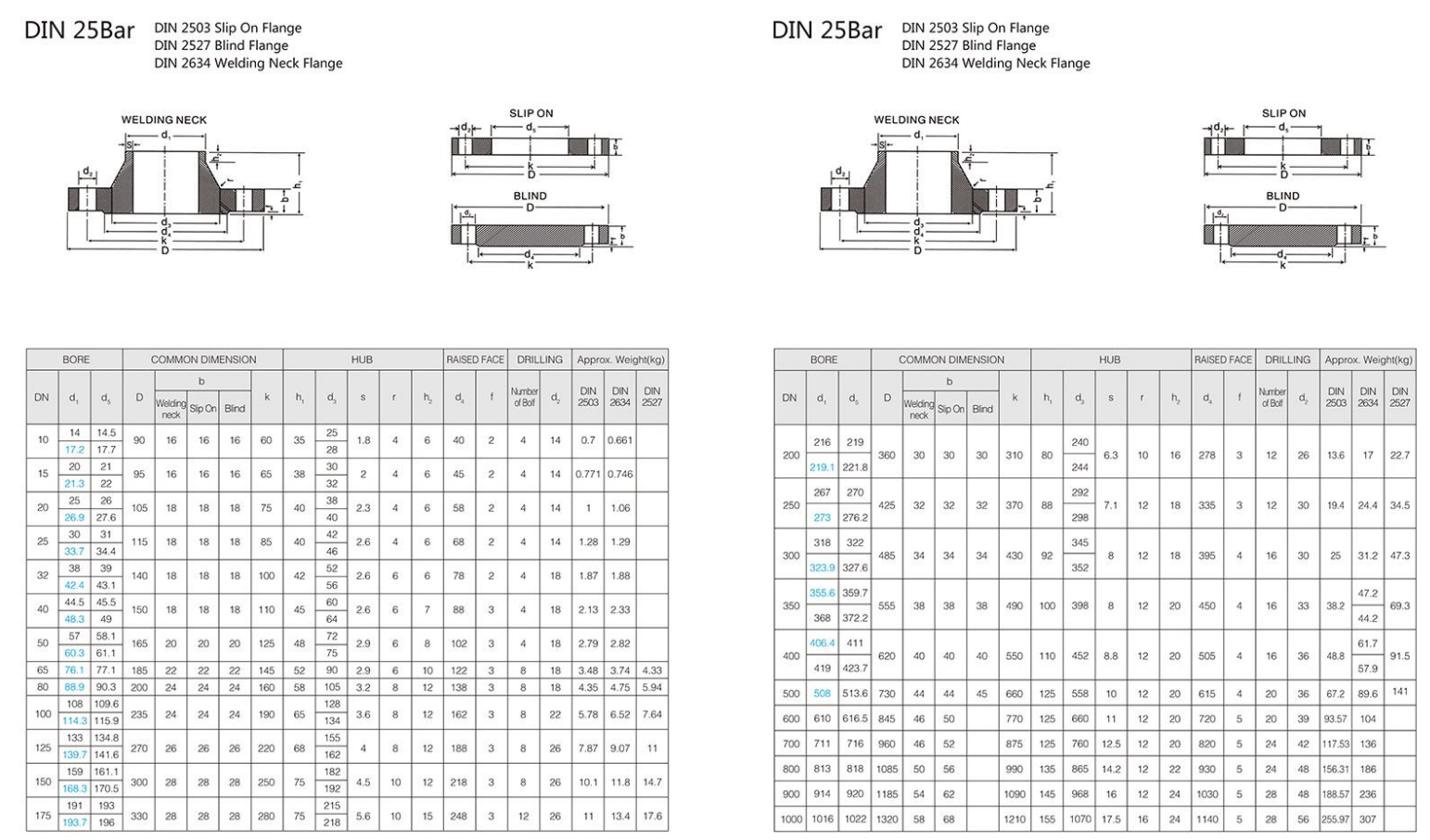

The dimensions of DIN PN10 flanges are strictly regulated to ensure compatibility with pipes and other fittings. Typically, DIN PN10 flanges have raised faces, and the thickness varies depending on the flange size. For instance, a DN50 flange might have a thickness around 10 mm, while a DN100 flange may have a thickness of approximately 12 mm. The bolt hole pattern also adheres to precise dimensions, facilitating a tight, leak-proof seal when connected to another flange.

din flange pn10

Applications of DIN PN10 Flanges

The versatility of DIN PN10 flanges makes them suitable for a variety of applications across multiple sectors, such as

1. Water Supply and Sewerage Systems Due to their good sealing properties and adequate pressure resistance, they are frequently used in potable water systems and wastewater management.

2. Chemical Processing In environments where chemicals are transported, DN flanges made from appropriate materials (like stainless steel) can resist corrosive substances.

3. Oil and Gas Industry They are also utilized in oil and gas pipelines where controlled pressure and reliability are essential.

4. HVAC Systems In heating, ventilation, and air conditioning systems, DIN PN10 flanges are employed to connect various components efficiently.

The Importance of Proper Installation

For DIN PN10 flanges to function effectively, proper installation practices must be observed. This includes ensuring that the flange surfaces are clean and free of debris, aligning the flanges correctly, and applying the appropriate torque to the bolts. Over-tightening can lead to damage, while under-tightening may result in leaks, making it essential to adhere to manufacturer specifications and guidelines.

Conclusion

DIN PN10 flanges represent an indispensable part of modern piping technology, providing robust solutions for connecting pipes and equipment across various industries. Their standardization ensures compatibility and reliability, while their versatility makes them a favored choice in many engineering applications. Understanding the characteristics, specifications, and proper installation practices of these flanges is crucial for engineers and technicians alike, ensuring the efficiency and safety of piping systems. As industries continue to evolve, the relevance of DIN flanges and their ability to adapt to new challenges remains steadfast.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024