-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 04, 2024 08:12 Back to list

en 1092 1 type 02

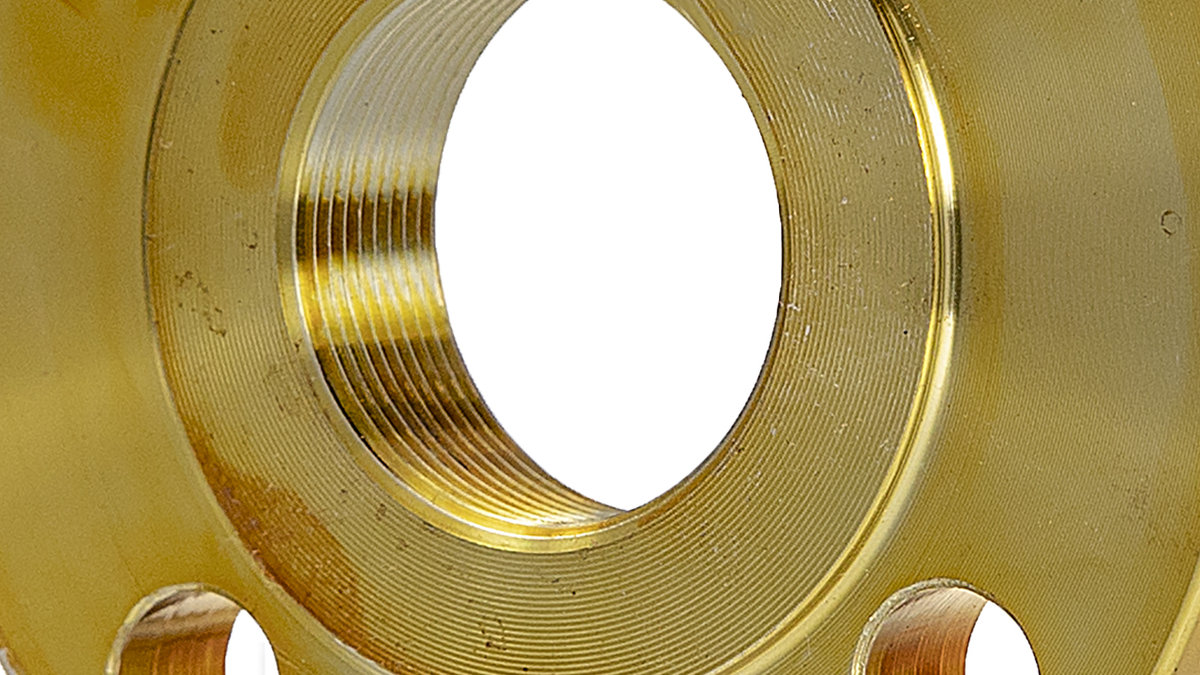

Exploring the Essence of EN 1092-1 Type 02 Flanges

In the realm of mechanical engineering and piping systems, the significance of standardized components cannot be overstated. Among these, EN 1092-1 Type 02 flanges play a crucial role in ensuring the integrity and efficiency of connections within various structures, including pipelines and pressure vessels. This article delves into the specifications, applications, and benefits of EN 1092-1 Type 02 flanges.

Exploring the Essence of EN 1092-1 Type 02 Flanges

One of the primary materials used in manufacturing EN 1092-1 Type 02 flanges is carbon steel, but they can also be produced from stainless steel and other alloys depending on the application requirements. The choice of material is paramount, as it directly influences the flange’s resistance to corrosion, temperature fluctuations, and mechanical stress. For instance, stainless steel flanges are ideal for environments exposed to harsh chemicals, while carbon steel flanges are commonly used for general applications.

en 1092 1 type 02

The applications of EN 1092-1 Type 02 flanges are diverse. They are prevalent in industries such as oil and gas, water treatment, chemical processing, and power generation. Their ability to provide robust connections in high-pressure environments makes them essential in these sectors. Proper installation and adherence to technical specifications ensure that these flanges can withstand the operational demands posed by the fluid systems they serve.

Moreover, the benefits of utilizing EN 1092-1 Type 02 flanges extend beyond their structural integrity. Standardization facilitates easy interchangeability among different manufacturers, which simplifies maintenance and reduces downtime in industrial applications. This compatibility further enhances operational efficiency and cost-effectiveness.

In conclusion, EN 1092-1 Type 02 flanges are integral components in modern engineering, facilitating safe and reliable connections in a multitude of applications. Their robust design, material versatility, and compliance with European standards not only enhance performance but also promote safety across various industries. As technology advances, the continued evolution of such standards will further ensure that these crucial components meet the ever-growing demands of the industrial landscape.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024