-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 04, 2024 15:59 Back to list

Similar Standards for Flanges and Fittings in Industrial Applications and Their Specifications

EN 1092-1 Understanding Flange Standards for Industrial Applications

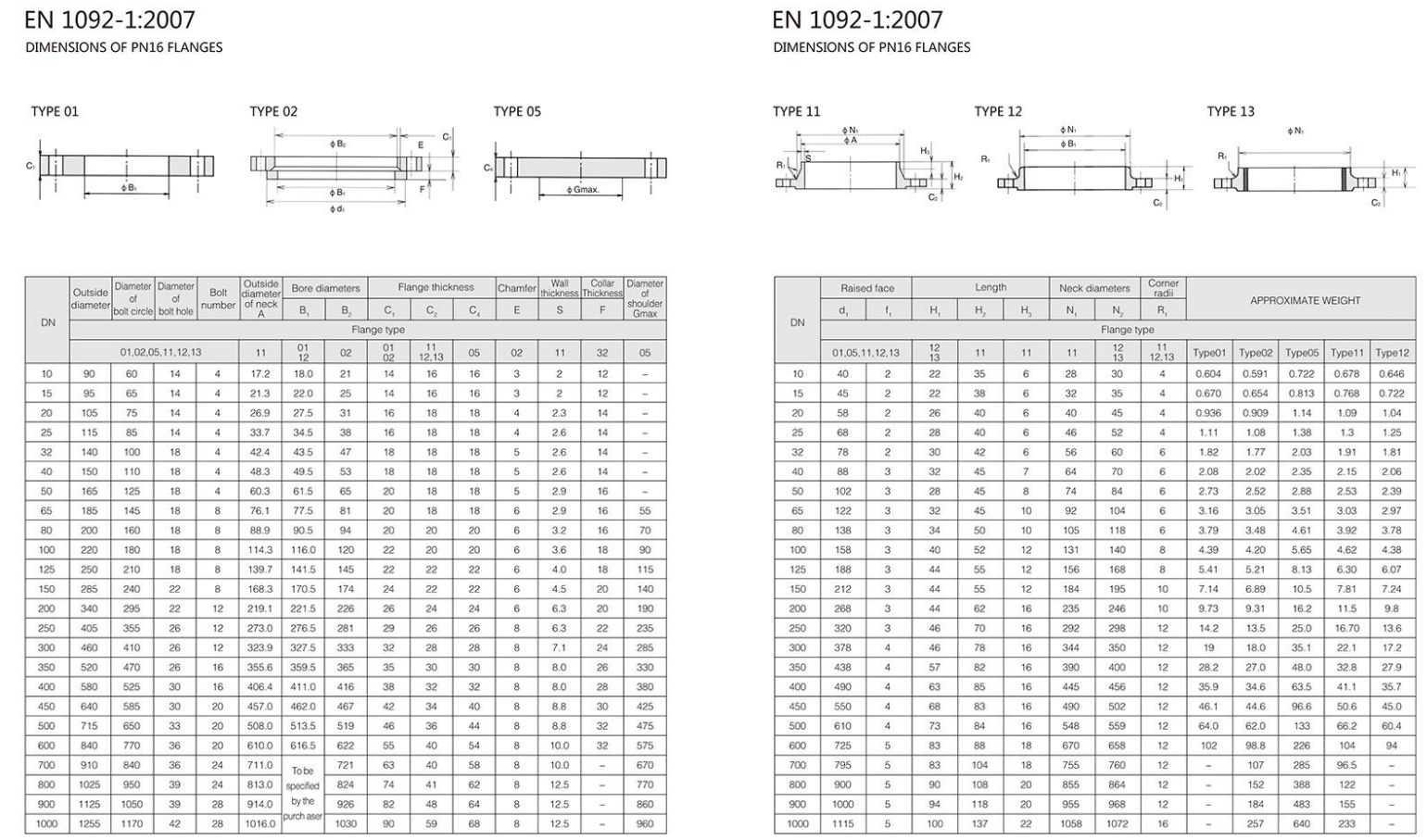

The EN 1092-1 standard is an essential guideline in the realm of piping and pressure vessel construction. Commonly referred to in the engineering and manufacturing sectors, this standard specifically outlines the requirements for circular flanges. Flanges are integral components in piping systems, serving as the connection points for pipes, valves, and other mechanical components. Understanding this standard is vital for manufacturers, engineers, and pipeline operators who must ensure the safety and reliability of their systems.

Flanges are used extensively across various industries, including oil and gas, water treatment, power generation, and chemical processing. EN 1092-1 provides a comprehensive framework that addresses the geometry, dimensions, material specifications, pressure ratings, and testing requirements for these critical components. By adhering to this standard, companies can maintain consistency in their products, ensure interoperability between different systems, and meet regulatory compliance.

EN 1092-1 Understanding Flange Standards for Industrial Applications

Material selection is another critical factor addressed by the EN 1092-1 standard. Different applications may require flanges made from various materials, such as carbon steel, stainless steel, or special alloys. The standard outlines the material properties and classifications needed to withstand the specific pressures and temperatures encountered in particular environments. For example, flanges used in high-temperature systems must possess high tensile strength and resistance to corrosion. By specifying these material requirements, EN 1092-1 ensures that flanges remain reliable and safe under operational conditions.

en1092 1 01a

Furthermore, the standard incorporates various pressure ratings, known as nominal pressure classes. These classes, typically ranging from PN 2.5 to PN 40, denote the maximum allowable pressure that a flange can withstand at high temperatures. This rating helps engineers select the appropriate flange for their applications, avoiding potential failures or accidents resulting from pressure exceedance. The pressure rating system provides a systematic approach to ensure that all components in a pipeline can handle intended operational pressures.

Testing and verification procedures are also vital elements of EN 1092-1. The standard outlines the specific tests that flanges should undergo before they can be put into service. These tests may include visual inspections, pressure tests, and non-destructive testing methods to detect any potential flaws or weaknesses in the material. By enforcing rigorous testing standards, EN 1092-1 helps to minimize the risk of failures and enhances the safety of piping systems.

Compliance with EN 1092-1 not only promotes safety but also benefits manufacturers by broadening their market reach. Adhering to established standards makes it easier for companies to export their products internationally, as many countries recognize EN standards. This can substantially increase a company's competitiveness in the global market, allowing for greater sales and collaboration opportunities.

In conclusion, EN 1092-1 serves as a critical framework for the design, manufacture, and application of flanges in industrial piping systems. By providing clear guidelines regarding dimensions, materials, pressure ratings, and testing protocols, the standard ensures that flanges perform reliably and safely in various applications. For engineers and manufacturers, familiarizing themselves with EN 1092-1 can lead to improved product quality, enhanced safety, and greater market accessibility. As industries continue to evolve and expand, adherence to such standards will remain paramount in ensuring operational efficiency and safety for all stakeholders involved.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024