-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 12, 2024 23:09 Back to list

A Comprehensive Guide to EN 1092-1 Flanges and Their Specifications

Understanding EN 1092-12001 and Its Importance in Flange Standards

The EN 1092-12001 standard is a vital aspect of the European framework for industrial flanges, particularly in applications involving piping systems. It provides specifications for the design, manufacturing, and testing of flanges used in various sectors, ensuring interoperability, safety, and performance across different industries. This standard is part of a broader series that encompasses various flange types and specifications, demonstrating its significance in ensuring quality and consistency within the European market.

Historical Context and Development

The EN 1092 standard was developed to address the growing need for uniform standards in the manufacture of flanges. Prior to its establishment, different countries within Europe had their own national standards, which often led to inconsistencies and complications in cross-border trade and engineering applications. The standardization process aimed to create a harmonized approach that would facilitate cooperation and improve safety across the European Union.

EN 1092-12001 specifically covers circular flanges for piping applications, detailing critical aspects such as dimensions, tolerances, material grades, and performance characteristics. The standard applies to both manufacturers and end-users, ensuring that flanges comply with rigorous requirements that promote quality and safety.

Key Features of EN 1092-12001

1. Flange Types EN 1092-1 classifies flanges into several types (e.g., blind, weld neck, slip-on, and threaded flanges), allowing engineers and designers to select the most suitable flange type for their specific applications.

2. Dimension Standards The standard specifies precise dimensions, including nominal sizes and pressure ratings, which are crucial for ensuring proper fit and function within piping systems. This standardization helps prevent leaks and structural failures, which can have severe safety implications.

en1092 1 01a

3. Material Specifications EN 1092-12001 includes information on material grades, ensuring that flanges are manufactured from materials suitable for the intended service conditions. This encompasses resistance to corrosion, temperature, and pressure, thereby enhancing the longevity and reliability of piping systems.

4. Testing Requirements The standard outlines various testing methods to verify the mechanical properties and integrity of flanges. These tests ensure that the flanges can withstand the pressures and stresses encountered in real-world applications.

5. Marking and Documentation The standard mandates appropriate marking and documentation for all flanges produced under its guidelines. This includes identifying the manufacturer, material grade, and any applicable certifications, promoting traceability within the supply chain.

Importance of EN 1092-12001

The significance of EN 1092-12001 extends beyond mere compliance with regulations. It plays a critical role in enhancing safety, efficiency, and interoperability in industrial applications. By adhering to these standards, manufacturers can reduce the risk of failures associated with improper flange selection or manufacturing defects, which can lead to costly downtime and potential hazards.

Furthermore, the standard fosters a competitive environment among manufacturers by providing clear criteria for quality and performance. This encourages innovation and improvement in flange design and manufacturing processes. As a result, industries such as oil and gas, chemical processing, and water treatment benefit from the reliability and quality assured by standardized components.

Conclusion

In conclusion, EN 1092-12001 serves as a cornerstone in the European standardization of flanges. By establishing comprehensive guidelines for flange types, dimensions, materials, and testing, the standard promotes safety, quality, and interoperability across various industries. Its implementation not only enhances the performance of piping systems but also supports economic growth through increased efficiency and reliability. For engineers, manufacturers, and users alike, understanding and adhering to EN 1092-12001 is essential for achieving the highest standards of quality and safety in their operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

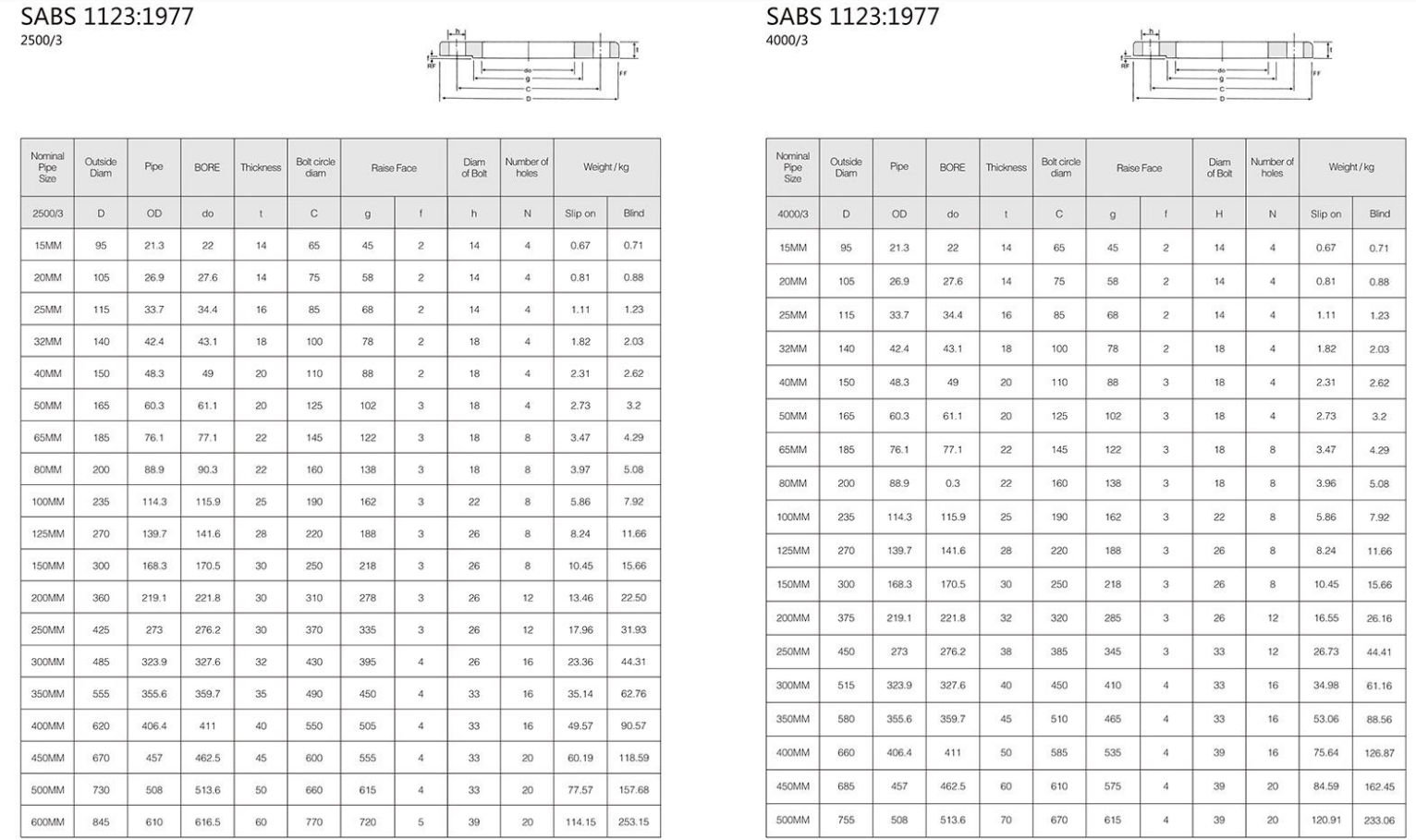

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024