-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 11, 2024 04:22 Back to list

Similar Title to EN 1092-1 Type 02 Specifications for Flanges and Connections

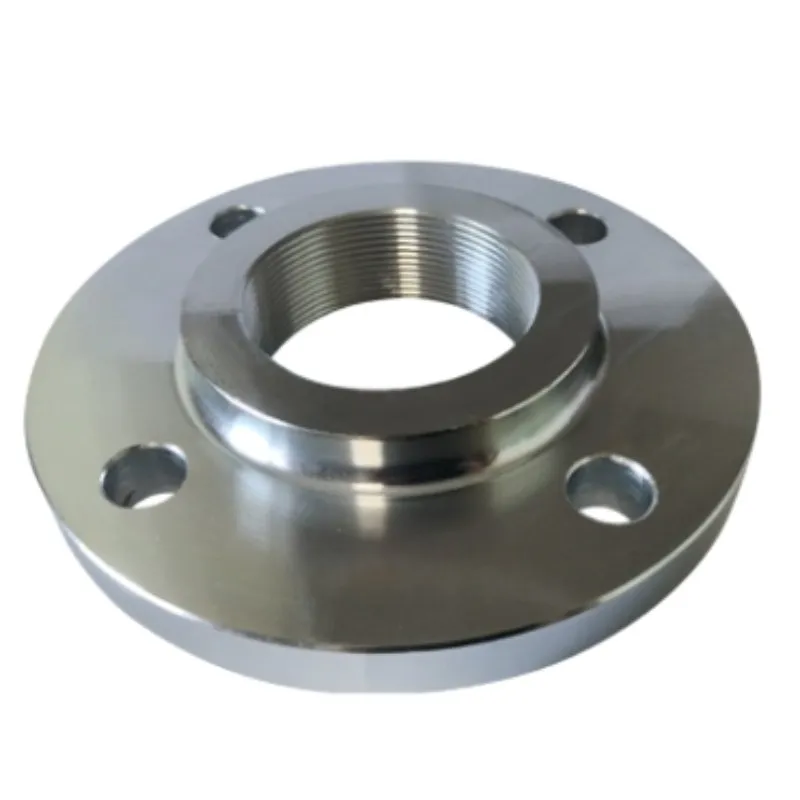

Understanding EN 1092-1 Type 02 Flanges An Overview

Flanges are critical components in various piping systems and applications, designed to connect piping, valves, pumps, and other equipment. Among the different flange standards used across industries, EN 1092-1 provides a comprehensive framework for the design and manufacture of flanges, particularly in Europe. Within this standard, Type 02 flanges play a specific role that warrants closer examination.

What is EN 1092-1?

EN 1092-1 is a European standard that specifies requirements for circular flanges for pipes, valves, fittings, and accessories. It outlines several types of flanges, each serving a distinct purpose. The standard helps ensure consistency and reliability in the flanges used in various installations, contributing to safety and operational efficiency.

Characteristics of Type 02 Flanges

Type 02 flanges, also known as flat or raised face flanges, are characterized by their particular facing types and design. These flanges typically come with a flat surface or a slightly raised face, which allows for a proper seal when mated with another surface. The design of Type 02 flanges makes them versatile and suitable for various applications, especially in low to medium-pressure systems.

Dimensions and Specifications

EN 1092-1 Type 02 flanges are available in various sizes, ranging from small diameters to very large ones, accommodating different pipeline requirements. The dimensions, including the outer diameter, thickness, and bolt hole diameters, are precisely defined in the standard, which ensures that they fit seamlessly with corresponding flanges. Furthermore, the standard classifies flanges by pressure ratings (PN) and material types, which can vary widely—from carbon steel to stainless steel—depending on the application's demands.

en1092 1 type 02

Applications of Type 02 Flanges

Type 02 flanges find widespread application across numerous sectors. In the chemical industry, for instance, they are commonly used to connect pipes carrying corrosive substances, where a secure and leak-proof joint is critical. Water treatment facilities also utilize these flanges for their robust design and ease of installation, ensuring the system's integrity under varying pressures.

In the oil and gas industry, Type 02 flanges play a vital role in maintaining the safety and efficiency of pipelines, where high-pressure conditions often prevail. Their compatibility with various sealing materials allows for flexibility in applications and enhances their performance in dynamic environments.

Installation and Maintenance

Proper installation of Type 02 flanges is essential for ensuring the integrity of the connected system. It is crucial to follow industry best practices, which typically involve cleaning the mating surfaces, applying the appropriate gasket material, and tightening the bolts to the recommended torque specifications. Over-tightening can lead to flange deformation or cracking, while under-tightening can cause leaks.

Regular maintenance checks are also important in prolonging the lifespan of these flanges. Inspecting for signs of wear, corrosion, or leaks can help identify potential issues before they escalate into more significant failures. Implementing a routine maintenance schedule can minimize downtime and maintain optimal operation within the system.

Conclusion

The EN 1092-1 Type 02 flanges are indispensable in modern engineering and construction practices, providing reliable connections in a variety of piping systems. Their flexibility, durability, and adherence to stringent industry standards make them a preferred choice among engineers and technicians. As industries continue to evolve and demand greater efficiency and safety, the importance of understanding and utilizing standards such as EN 1092-1 will only increase, ensuring that flanges meet the high expectations of today's complex fluid handling systems. Investing in high-quality Type 02 flanges and adhering to maintenance practices will lead to successful operations, reduced costs, and safer environments.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024