-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 21, 2024 01:21 Back to list

Understanding EN 1092 Flanges and Their Applications in Industry

Understanding EN 1092 Flanges Standards and Applications

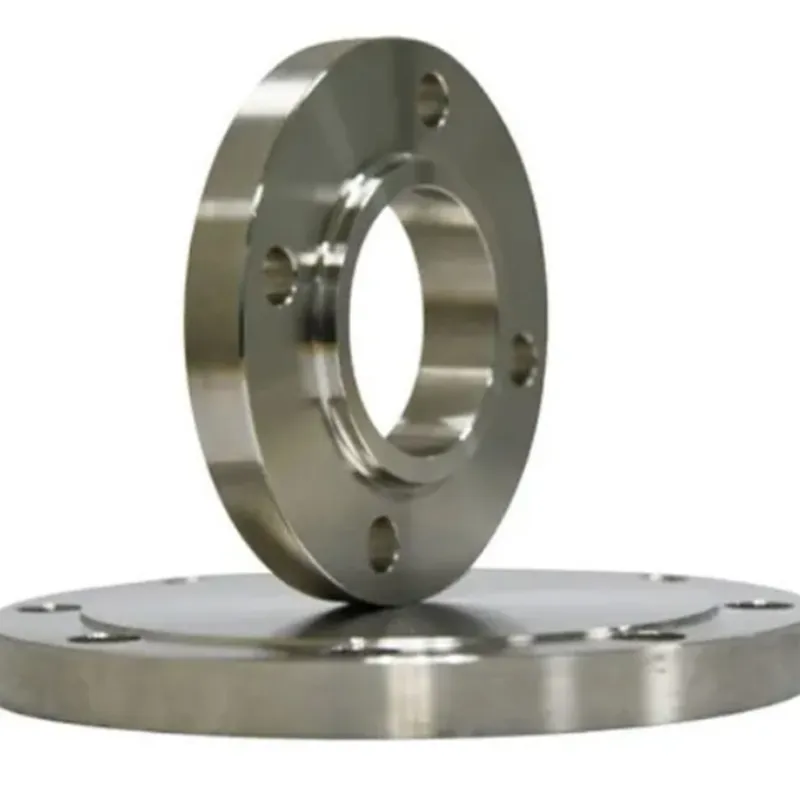

Flanges are critical components in piping systems, serving as points of connection between different segments of pipeline or equipment, and providing essential support in various mechanical and structural applications. Among the various flange standards in use today, the European Norm (EN) 1092 standard holds a significant place in ensuring compatibility, safety, and reliability in piping infrastructure across Europe and beyond. This article will delve into what EN 1092 flanges are, their types, specifications, and applications.

What is EN 1092?

EN 1092 is a European standard that specifies the requirements for flanges made from different materials, including steel and cast iron. This standard is crucial for ensuring interoperability among components of a piping system, particularly in industries such as oil and gas, water treatment, and other demanding environments. The EN 1092 standard provides guidelines concerning dimensions, tolerances, mechanical properties, and testing methods for flanges, thereby guaranteeing that they can withstand the high pressures and temperatures often encountered in industrial processes.

Types of EN 1092 Flanges

EN 1092 flanges can be classified based on several criteria, including the type of sealing face, flange shape, and pressure rating. The standard covers various types, including

1. Type 1 Flanges (Flat Face) These flanges have a flat sealing surface and are commonly used in low-pressure systems where leak prevention is a priority. 2. Type 2 Flanges (Raised Face) Featuring a raised sealing area, these flanges are designed for high-pressure applications and are widely used in the petrochemical industry.

3. Type 3 Flanges (RTJ - Ring Type Joint) These flanges have a groove for a ring gasket, providing a reliable seal even under extreme conditions.

Each of these types has specific use cases, and the selection often depends on the application, pressure ratings, and the materials being connected.

Specifications and Standards

According to EN 1092, flanges are available in various pressure ratings, denoted in PN (pressure nominal), which ranges from PN 2.5 to PN 40. The material grade is also an essential factor, influencing the flange's strength and corrosion resistance. Common materials include

en1092 flange

- Carbon Steel (e.g., S235, S275, S355) - Stainless Steel (e.g., 304, 316) - Cast Iron (e.g., EN-GJS-400-15)

The EN 1092 standard specifies dimensions such as the outer diameter, bolt circle diameter, number of bolt holes, and hole diameter, ensuring standardized production and interchangeability. Additionally, these flanges are often subjected to tests to assess their mechanical properties, including tensile strength and hardness, as well as non-destructive tests to detect any surface defects.

Applications of EN 1092 Flanges

The versatility of EN 1092 flanges makes them suitable for a wide range of applications

- Oil and Gas Industry EN 1092 flanges are commonly used in oil and gas pipelines due to their high pressure and temperature resistance. Their reliability is paramount to ensure safe and efficient transportation of hydrocarbons.

- Water Treatment In water treatment facilities, these flanges help connect different sections of piping, facilitating the flow of water through treatment processes.

- Chemical Processing With the variety of materials and types available, EN 1092 flanges are widely used in chemical processing plants, where the compatibility of materials with various chemicals is crucial.

- HVAC Systems Flanges play a significant role in heating, ventilation, and air conditioning systems, where they connect ducts, pipes, and machinery, ensuring an efficient flow of air and liquid.

Conclusion

Flanges are indispensable components in industrial applications, and understanding the EN 1092 standard is essential for engineers, designers, and procurement specialists involved in piping systems. By adhering to these standards, companies can ensure that their systems are not only compatible and safe but also efficient and reliable. The continued use and development of EN 1092 flanges will play a critical role in enhancing the performance of a wide array of industries, contributing to safe and sustainable engineering practices.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024