-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 01, 2024 09:45 Back to list

EN1092 Flange Specifications and Dimensional Guidelines for Standard Applications

Understanding EN 1092 Flange Dimensions

Flanges are critical components used in industries such as oil and gas, water treatment, and manufacturing, where they serve as the connection points between different piping systems. The European Norm (EN) 1092 standard specifically establishes guidelines for flanges in terms of dimensions, pressure ratings, and mechanical properties, ensuring uniformity and safety across various engineering applications.

EN 1092 flanges are commonly used in Europe, and they encompass several types, including the following Type 01 (plain), Type 02 (with a raised face), Type 03 (with a tongue), Type 04 (with a groove), and Type 05 (with a full face). Each type has distinct characteristics that make it suitable for specific applications and environments.

Dimensions and Standards

The dimensional specifications for EN 1092 flanges are categorized based on the nominal diameter (DN) and the pressure rating (PN). Nominal diameters range from DN10 (10mm) to DN600 (600mm) and beyond. The pressure ratings are defined as PN6, PN10, PN16, PN25, PN40, and PN63, where the number represents the maximum pressure in bars at which the flange can operate.

A critical aspect of flange design is its thickness, which varies according to the sought pressure and diameter. For instance, a PN10 flange is typically thinner than a PN40 flange of the same nominal diameter. This variation is crucial for maintaining integrity under different operating conditions and helps to prevent failure due to overpressure.

Material Considerations

Flanges conforming to the EN 1092 standard can be fabricated from various materials, including carbon steel, stainless steel, and alloy steels, which might undergo specific treatments to enhance strength and corrosion resistance. The choice of material is heavily influenced by the application environment; for instance, stainless steel flanges are preferred for chemical and marine applications due to their excellent resistance to corrosion.

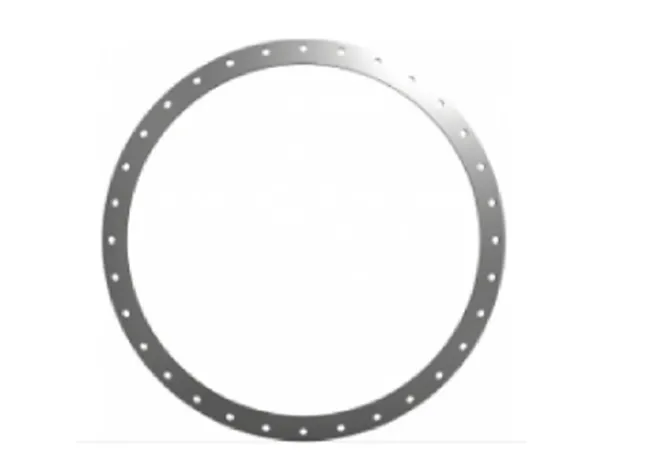

en1092 flange dimensions

Gasket and Bolt Specifications

When installing EN 1092 flanges, users must consider the appropriate type of gasket and bolting system to ensure a leak-proof seal. Gaskets are typically made from materials like rubber, PTFE, or metal, depending on the operating conditions. The bolt specifications, including size, grade, and tightening torque, are imperative for maintaining the required bolt tension and flange separation.

Importance of Compliance

Compliance with the EN 1092 standard not only guarantees interoperability among various flange types but also enhances safety and reliability in operations. Engineers and professionals must ensure that flanges meet the predetermined specifications to avoid potential failures that could lead to costly downtime or hazardous incidents.

Conclusion

In the ever-evolving landscape of engineering and fluid dynamics, understanding the dimensions and specifications of EN 1092 flanges is essential. With their diverse types and rigorous standards, these flanges serve as the backbone of many piping systems. By adhering to the guidelines of the EN 1092 standard, engineers can ensure the safe and efficient operation of their systems, ultimately contributing to overall industry reliability.

In summary, EN 1092 flanges represent a vital component in many industrial applications, defined by their dimensional accuracy and material integrity. Knowledge of flange types, pressure ratings, and installation techniques is essential for professionals looking to optimize performance in their respective fields.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024