-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 20, 2024 12:47 Back to list

en1092 pn10

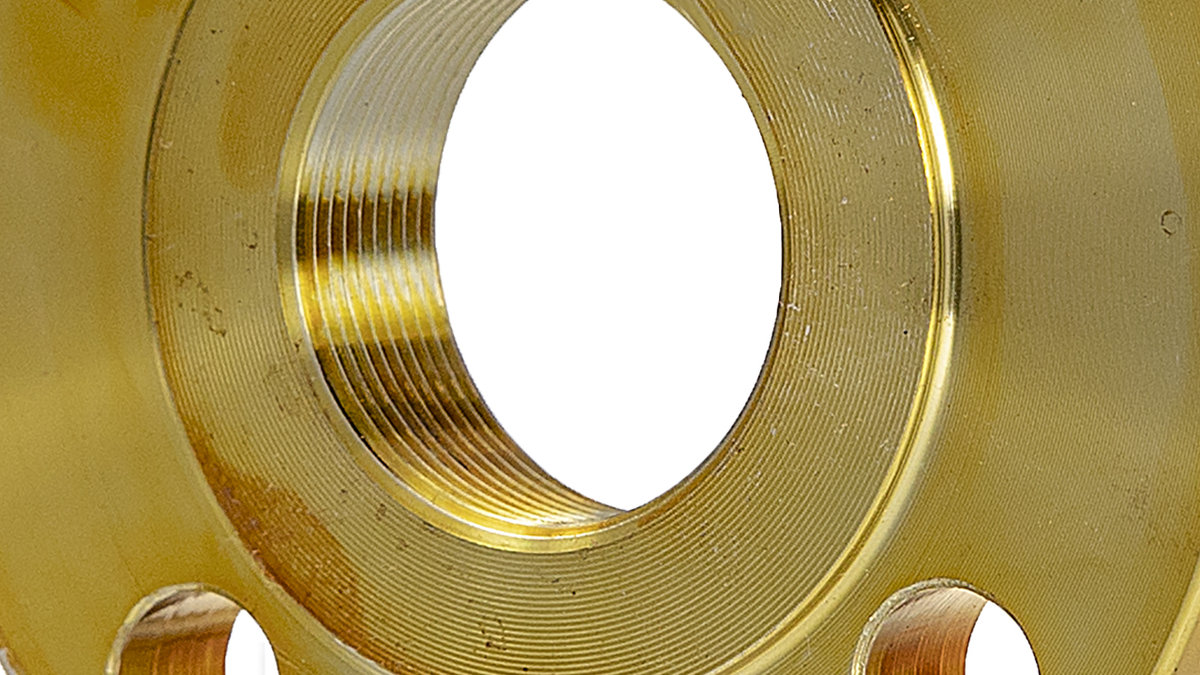

Understanding EN 1092-1 PN10 Flanges Key Features and Applications

EN 1092-1 is a crucial standard in the world of industrial piping and flanges. Specifically, it addresses the specifications for flanges made of various materials, including carbon steel, stainless steel, and other alloys. Among the various pressure ratings stipulated in this standard, PN10 is particularly significant, especially for applications where moderate pressure levels are prevalent. This article explores the characteristics, applications, and benefits of EN 1092-1 PN10 flanges.

What is PN10?

The designation PN stands for Pressure Nominal, which refers to the maximum pressure that a flange can withstand at a specific temperature. In the case of PN10, it denotes that these flanges are designed to handle pressures up to 10 bar (approximately 145 psi). This pressure rating is ideally suited for a range of applications in various sectors, including water supply, heating systems, and other industrial processes.

Material Specifications

Flanges compliant with EN 1092-1 can be manufactured from several materials, allowing for flexibility and suitability in a wide array of environments. Common materials include

1. Carbon Steel Known for its strength and durability, carbon steel is frequently used in applications requiring high pressure and temperature resistance. 2. Stainless Steel Offering excellent corrosion resistance, stainless steel versions of PN10 flanges are preferable in environments that involve exposure to moisture or corrosive substances.

3. Alloy Steel For high-strength applications, flanges made from alloy steel provide enhanced mechanical properties while maintaining the necessary weight-to-strength ratio.

4. Ductile Iron This material is often used for water and wastewater applications due to its excellent mechanical properties and resistance to corrosion.

Key Features of EN 1092-1 PN10 Flanges

1. Dimensions EN 1092-1 specifies a range of dimensions for PN10 flanges, ensuring compatibility and interchangeability with other piping systems. This includes variations in face types, such as flat, raised, or even weld neck designs.

en1092 pn10

2. Bolt Circles The standard also outlines bolt circle diameters, which are critical for ensuring that the flanges fit securely with the mating flanges without any misalignment.

3. Surface Finishes To enhance sealing capabilities, PN10 flanges typically come with specific surface finish requirements, which can help achieve a tighter seal within pipelines.

4. Testing and Certification Flanges manufactured to EN 1092-1 PN10 standards undergo rigorous testing to ensure they meet the required strength, durability, and compatibility with the fluids they will convey. Certification ensures reliability and conformity.

Applications of PN10 Flanges

The applications for EN 1092-1 PN10 flanges are vast

- Water Distribution In municipal water systems, PN10 flanges are commonly employed in pipelines that transport drinking water or wastewater.

- HVAC Systems Heating, ventilation, and air conditioning systems utilize PN10 flanges for various components, including pumps and heat exchangers, where moderate pressure ratings are necessary.

- Industrial Processes Industries involved in chemical processing, petrochemicals, and food and beverage often use these flanges in their piping systems to maintain operational integrity under moderate pressures.

Conclusion

EN 1092-1 PN10 flanges are a vital component in modern piping systems, providing a reliable solution for medium-pressure applications in various industries. Their compatibility with multiple materials, stringent manufacturing standards, and versatility make them an essential choice for engineers and industry professionals. Understanding the specifications and applications of PN10 flanges ensures that the right materials and designs are selected, contributing to the efficiency and safety of industrial processes. With the continued evolution of material science and engineering, EN 1092-1 PN10 flanges will remain a staple in the design and fabrication of piping systems for many years to come.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024